The crankshaft position sensor (CKP) is used to determine the position of the crankshaft and the position of the piston of the engine which is necessary to manage the operation of fuel injectors and spark plugs. It is one of the major sensors that help to manage the operating time of the spark plug and the fuel injector.

Let’s get a deep dive into the Crankshaft position sensor.

In this article, we’re going to discuss:

- What is the Crankshaft position sensor?

- How does the crankshaft position sensor help to control the engine running?

- Different types of Crankshaft position sensors:

3.1. Hall effect sensor:

3.2. Inductive crankshaft sensor:

3.3. Optical crankshaft position sensor: - Symptoms of faulty crankshaft position sensor:

- Why engine never start after the crankshaft position sensor becomes faulty?

- Final words:

What is the Crankshaft position sensor?

The crankshaft position sensor is an electronic device that is used to decide the position of the crankshaft and the position of the piston.

It plays a vital role in multicylinder engines in which all the pistons have variable ignition timing.

The crankshaft position sensor is located near the crankshaft or flywheel or near the camshaft.

How does the crankshaft position sensor help to control the engine running?

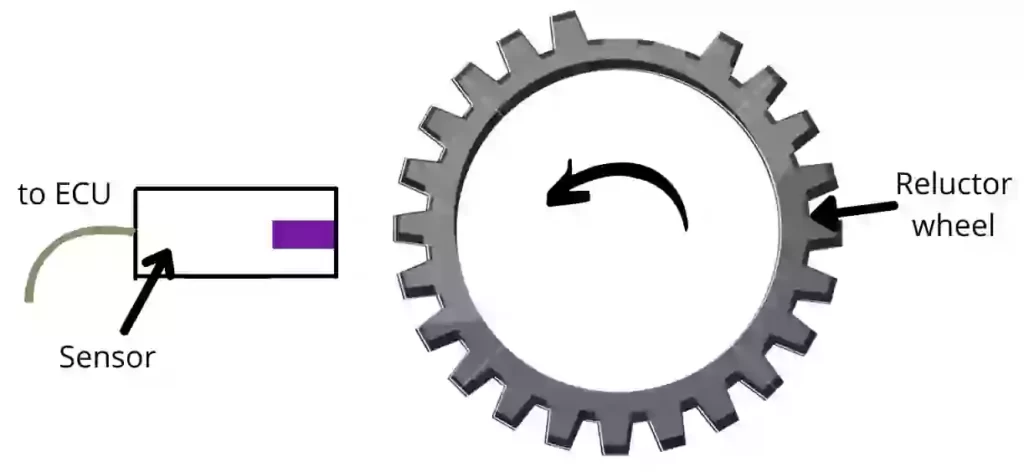

As shown in the image, the reluctor wheel has the teeth on the circumference but at the specific location, it has a few missing teeth which are kept intentionally.

This reluctor wheel is mounted on the crankshaft of the engine and it rotates with the rotation of the engine.

The sensor is mounted near the teeth of the reluctor wheel. The sensing element of the sensor is under the magnetic field of a permanent magnet. As the reflector starts to rotate, the teeth of the reflector disturb the magnetic field of the sensing element. This change in magnetic field fluctuates the resistance of the sensing element and these fluctuations help to generate a voltage pulse signal.

When the no teeth portion of the reluctor wheel is in front of the sensor, the sensor never generates a pulse signal.

At the no pulse region of the pulse signal the position of the piston is arranged in such a way that, it is near to the TDC.

This pulse signal generated by the crankshaft position sensor is provided to the ECU.

Therefore from this data, the ECU knows the exact position of the piston. Therefore from this data, the ECU supplies current to the spark plug and fuel injector for the ignition. This data is also used to measure the RPM of the engine.

Different types of Crankshaft position sensors:

Some of the different sensors used to sense the crankshaft position are given below:

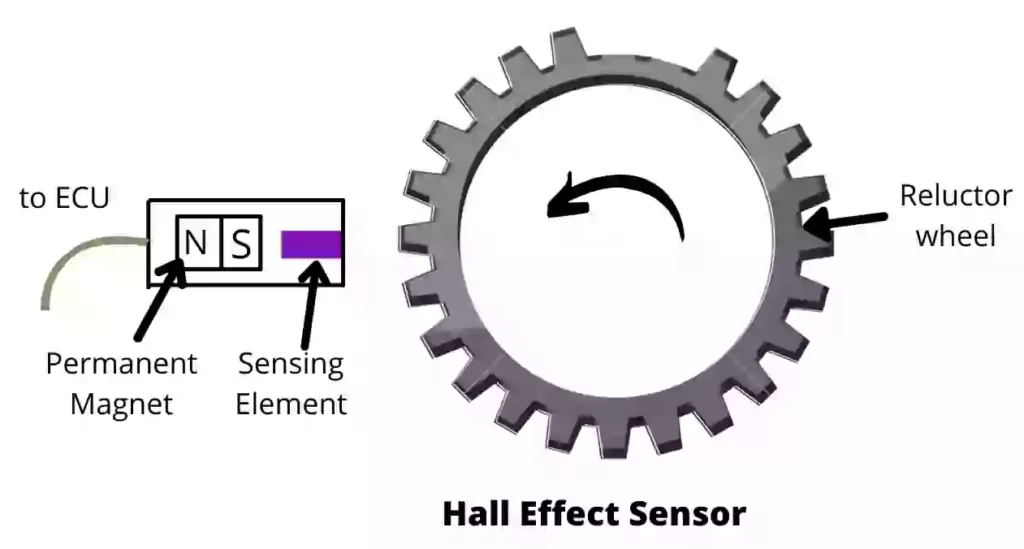

1) Hall effect sensor:

It consists of the permanent magnet along with the sensing element. The sensing element is under the magnetic field of a permanent magnet. When the teeth of the relative will disturb the magnetic field, the resistance of the sensing element also changes. This fluctuation in resistance is used to create a pulse voltage signal.

2) Inductive crankshaft sensor:

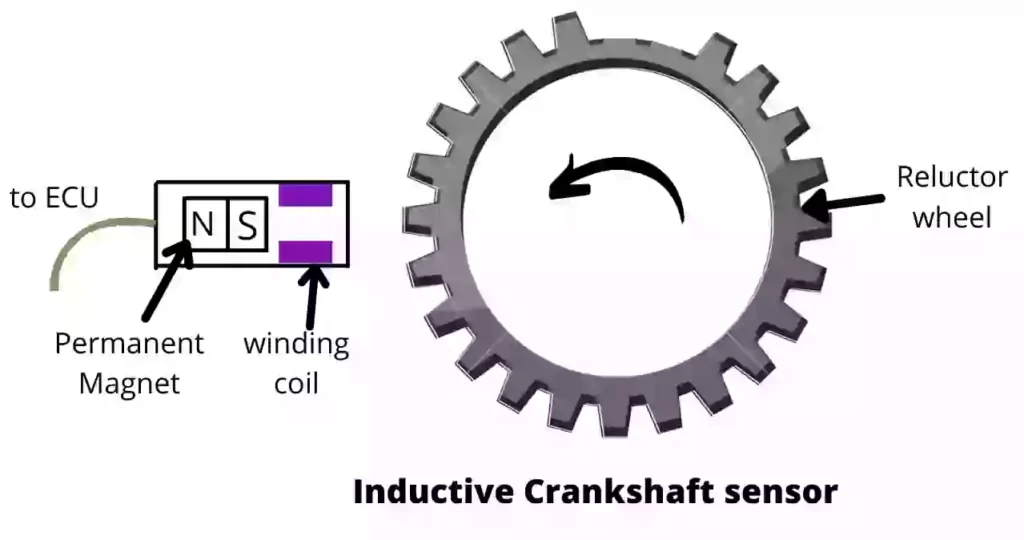

In this type of sensor, the sensor consists of a permanent magnet and winding coil.

When the reluctor wheel is in stop condition, two winding coil is under a constant magnetic field of the permanent magnet. But when the reluctor wheel starts to rotate the teeth of reluctor disturb the magnetic field. Therefore due to the change in a magnetic field, the EMF is generated inside of the winding coil which is used to generate a pulse signal.

3) Optical crankshaft position sensor:

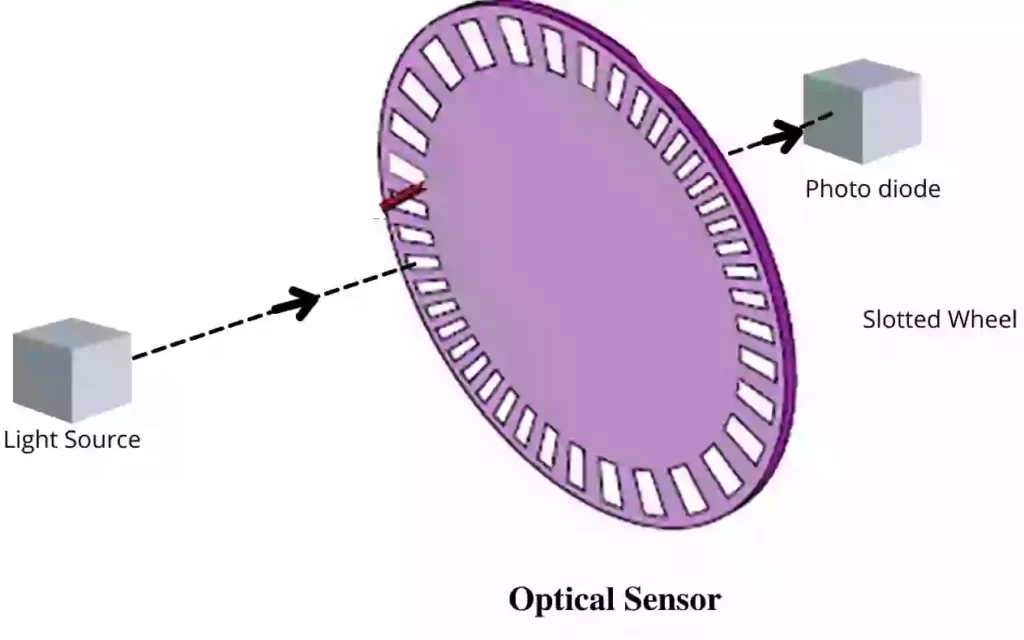

As shown in the figure, the slotted wheel is mounted on the crankshaft. The light source and photodiode are arranged on either side of the slotted wheel. All these three components are arranged in such a way that when the slot on the slotted wheel comes between the light source and photodiode, the light will incident on the photodiode.

The resistance of the photodiode varies with the change in intensity of incident light. Hence when the slotted disc starts to rotate, then due to the fluctuations of the photodiode, the pulse signal is generated by the sensor. This pulsating signal is provided as input to the ECU.

Symptoms of faulty crankshaft position sensor:

The crankshaft position sensor can become faulty because of overheating or electrical problems. We have mentioned the following symptoms which will help you to identify that, the crankshaft position sensor needs to be checked:

- The ‘Check engine’ indicator becomes on.

- The engine may not start: As the sensor becomes faulty, it never sends input to the ECU. Hence the ECU never starts the ignition and fuel injection.

- Suddenly engine stops in running condition: as the sensor provides an even input to the ECU the engine may be stopped while in running condition or the vehicle may face the issue of uneven acceleration.

Why engine never start after the crankshaft position sensor becomes faulty?

The crankshaft position sensor sends the data to the ECU about the position of the piston in the cylinder. when the piston is nearest to the TDC, the ECU provides current to the spark plug and fuel injector therefore the engine starts its working.

But if the crankshaft position sensor never sends the signal to the ECU then the ECU will never control the functioning of the spark plug and fuel injector, therefore, the engine will remain in a stopped condition.

Final words:

The ECU is one of the major sensors that help to operate the functioning of spark plugs and fuel injectors. The engine will never start if this sensor never sends the signal. The crankshaft position sensor helps to increase the fuel economy of the engine.

Thanks for reading this article. If you have any queries regarding this article, drop them in below comment box.

Read also: