What is Abrasive jet machining?

Abrasive Jet Machining (AJM) is the process in which machining is done with the help of Abrasive particles and High-pressure air. The high-velocity abrasive particles strike the workpiece to remove the material from the workpiece.

It is one of the types of non conventional machining process used for hard materials.

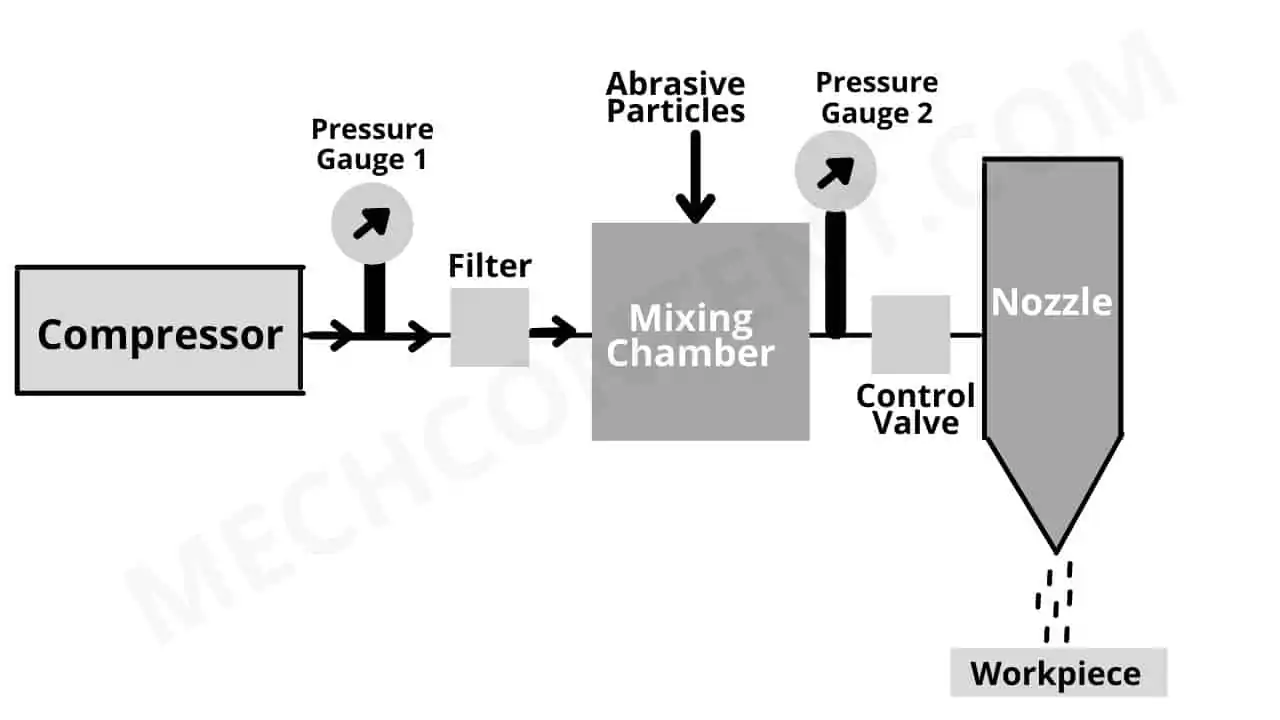

The below figure shows the basic block diagram for abrasive jet machining.

This machining method uses a jet of abrasive particles for the machining. These abrasive particles are of diamond dust, aluminum oxide, silicon carbide, etc.

The high-velocity jet of this abrasive particle strikes on the workpiece.

Contents:

Working principle:

This machining process uses the Kinetic energy of the compressed air with abrasive particles.

When high-velocity particles strike the workpiece surface, they remove the material from the surface of the workpiece.

Construction:

The Abrasive Jet Machining (AJM) consists of the following components:-

1) Compressor:- The Compressor is used to supply high-pressure air to the system. The compressor takes air from the atmosphere & compresses this air to high pressure.

2) Abrasive Particles:- The abrasive particles used in this process are diamond dust, aluminum oxide, silicon carbide, etc. The size of these particles is 10-40 microns.

The abrasive particles are strikes on material with a velocity of around 140-280 m/s.

3) Pressure Gauge 1:- The pressure gauge 1 helps in indicating the outlet pressure of the compressed air from the compressor. This helps to get the desired pressure on the system.

4) Filter:- The filter helps in removing dirt, and contaminants from the compressed air.

5) Mixing Chamber:- In this chamber the compressed air from the compressor and abrasive particles are mixed. This mixer chamber has two inlet pipes, one for compressed air and one for abrasive particles.

6) Pressure Gauge 2:- After the mixing chamber, the mixture flows through the control valve and pressure gauge 2 to nozzle. The pressure gauge 2 indicates the mixture pressure.

7) Flow control valve:- The flow control valve helps to control mixture flow as per requirement.

Working:

The compressed air from the compressor passed through the filter to the mixing chamber. The purpose of the filter is to remove dirt and contaminants.

In the mixing chamber compressed air and abrasive particles with each other. The mixing chamber has a vibrating device that helps in the proper mixing of the compressed air and abrasive particles.

This mixture leaves the mixing chamber and flows to the nozzle through the control valve. The operator uses this control valve to achieve the desired pressure at output.

The nozzle increases the velocity of the mixture so that the mixture can strike the workpiece with high velocity (Around 140-280 m/s).

The high-velocity mixture causes the material on the surface of the workpiece to be removed.

Advantages:

Abrasive jet machining has the following advantages:-

- Obtains high surface finish

- Accuracy up to 0.5mm

- Less power consumption

- It has the capacity to drill holes with intricate shapes in brittle & hard material.

- Less capital cost

Disadvantages:

Abrasive jet machining has the following disadvantages:-

- High nozzle wear due to the flow of abrasive particles.

- Less material removal rate.

- No contact between the tool and the workpiece.

Applications:

The applications of abrasive jet machining are as follows:

- Frosting of glass tubes.

- It is widely used in cutting and drilling.

- In the cleaning of brittle & hard objects.

- In paint removal of colored objects.

- In making high-quality surface parts.

FAQ:-

-

What is the principle of abrasive jet machining?

In abrasive jet machining high-velocity abrasive particles are hitted on the workpiece surface to remove the material.

-

What is abrasive jet machining used for?

Abrasive jet machining is widely used in cutting, and drilling hard material objects and in making high-quality surface parts.

-

What are the components of abrasive jet machining (AJM) ?

The abrasive jet machining setup mainly consists of a Compressor, Pressure gauge, Filter, Mixing chamber, Control valve, and Nozzle.

-

What are the disadvantages of abrasive jet machining?

The abrasive jet machining has the disadvantage of high nozzle wear and less material removal rate.

Read also: