What is bourdon tube pressure gauge?

Bourdon tube pressure gauge is a device used for sensing & measuring pressure. This device uses, bourdon tube as a pressure sensing element due to its elastic nature.

The bourdon tube is generally oval or elliptical in cross-section, with one end sealed & another end open for measurement of pressure. The tube is bend in C-Shape.

It was invented by Eugene Bourbon in 1849.

It can work for pressure limit up to 100000 psi. Hence, commonly used in many industrial applications.

Contents:

Working principle of bourdon tube pressure gauge:

The working of this gauge is based on the elastic nature of the bourdon tube.

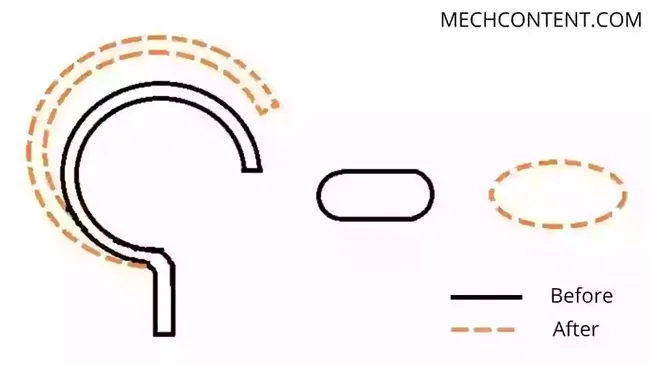

This tube has oval or elliptical shaped cross-section. When the tube gets pressurized, this elliptical shape tries to attain the circular shape due to hoop stresses onto the wall of the tube.

Due to this, C-shaped tube also tries to straighten. This causes displacement in the sealed end of the tube.

This movement of c-shape is magnified using gear sector & pinion arrangement to indicate the pressure.

Construction of bourdon tube pressure gauge:

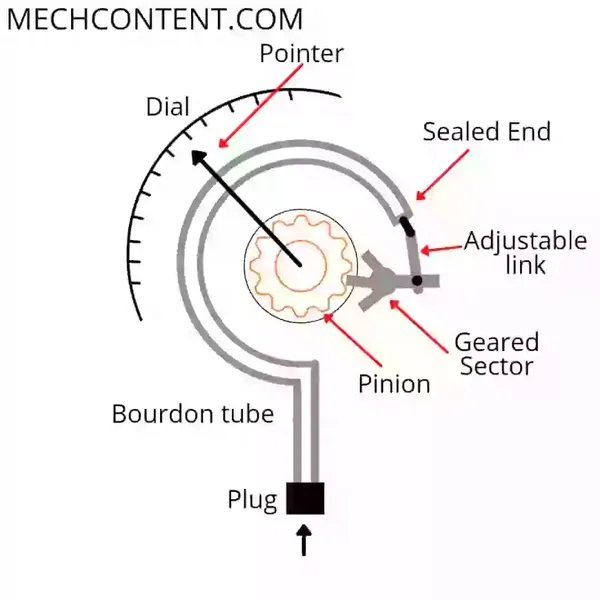

The below figure shows the basic structure of the bourdon tube gauge.

It generally consists of the following elements:

A) Bourdon tube :

Bourdon tube is oval or elliptical in cross-section of thickness between 0.01 to 0.05 inches.

It has one end sealed connected to a geared sector and pinion arrangement. The another end is open for pressure measurement & fixed into the socket. The socket has provision for attaching the gauge with equipment whose pressure has to measure.

The material of construction for the bourdon tube is stainless steel, phosphor bronze, etc.

Generally bourdon tube is made in three shapes, C-shaped bourdon tube, spiral shaped bourdon tube, helical bourdon tube.

C-shaped bourdon tube is widely used in industrial applications. The C-shaped bourdon tube is bend in circular are over an angle of 250 degree.

B) Geared sector & pinion arrangement:

The movement of the free sealed end is non-linear & smaller multiplication of movement of tip end is done by means of geared sector & pinion arrangement.

It is connected to the sealed end of the bourdon tube by means of an adjustable link.

C) Pointer and Dial : The pointer is mounted onto the spindle of the pinion wheel. The dial is circular arc-shaped fitted onto the housing.

Calibration of Bourdon tube pressure gauge is carried out by a deadweight tester.

Working of bourdon tube pressure gauge:

The open end of the bourdon tube is connected to the equipment or fluid transfer line whose pressure is to be measured.

When the fluid enters the bourdon tube, hoop stresses are generated into the tube, which tries to straighten the circular tube. This allows the sealed end of the tube to move in a non-linear manner.

This movement of the sealed end is magnified by a gear sector & pinion arrangement. It causes the pointer to move onto the calibrated dial.

When the pressure is removed, the bourdon tube regains its shape & it allows the pointer to move to its initial position.

Advantages of bourdon tube pressure gauge:

This pressure gauge has the following advantages:

- Simple in construction.

- It can be used for the wide pressure range.

- It gives high accuracy for high pressure.

- It is less costly.

- It gives very accurate results.

- It has good sensitivity.

- It gives continuous output.

- It can be used for the vacuum measurement.

Disadvantages of bourdon tube pressure gauge:

It has the following disadvantages.

- It is subjected to hysteresis.

- Slowly respond to changes in pressure.

- It is sensitive to shock & vibration.

Applications of bourdon tube pressure gauge:

Following are some of the applications where this pressure gauge is mounted:

- Pressure vessel

- Air tank

- Gas pipelines

- Material/Fluid pipelines

- Boilers

- Vacuum gauges

- High pressure reservoirs

- Fire extinguishers tank

Read also: