Hello friends, In the last article we have gone through the discussion on the steam turbine. As there are different methods used to improve the performance of the steam turbine, thus in this article, we will look at one among them: Compounding of steam turbine.

The compounding of steam turbine is done to reduce the speed of the rotor by arranging the number of stages of the turbine on a single rotor. As a result, the energy of the steam is taken partially by each stage of the turbine, resulting in a reduction in turbine speed.

Contents:

What is Compounding of steam turbine?

Compounding is the multi-staging of the steam turbine to reduce the speed of the rotor.

The expansion of steam in a single-stage turbine results in a very high speed of the rotor. The too-high speed attained by a single-stage turbine can create high vibrations and also has other drawbacks. To avoid these disadvantages of the single-stage turbine, the compounding is done in steam turbines.

The compounding of a turbine is achieved by arranging a number of stages on the same rotor shaft where each stage consists of sets of moving blades, fixed blades, and nozzles. In a compounded steam turbine, the energy of the steam is partly extracted by each stage so that the rotor can run at a slower speed.

The compounding of impulse steam turbines can be done by using these different methods:-

- Velocity compounding

- Pressure compounding

- Pressure- velocity compounding

Necessity of compounding of steam turbine:

The compounding of steam turbines is necessary to reduce the speed of the turbine rotor, thus it helps to overcome the disadvantage caused by the very high speed of the turbine.

When the high-pressure steam gets expanded into the ring of nozzles, the steam gains very high velocity.

If this high-speed steam is passed over a single set of rotor blades then the rotor can attain a very high speed.

This higher speed of the rotor causes very high vibrations in the turbines as well as it also creates high centrifugal force into the rotating components, which can damage the turbine.

Also, the kinetic energy of the steam does not get completely utilized by the single rotor. Thus a lot of energy gets losses in the exhaust steam.

Thus the compounding of the steam turbine is necessary to overcome these disadvantages, in which the energy of the high-pressure steam is utilized in multiple numbers of stages mounted on the same rotor.

Different types of compounding in steam turbine:

The different methods of compounding of a steam turbine are as follows:-

1] Velocity compounding of steam turbine:

It is a method of compounding the steam turbine in which the velocity of steam is dropped in a number of stages.

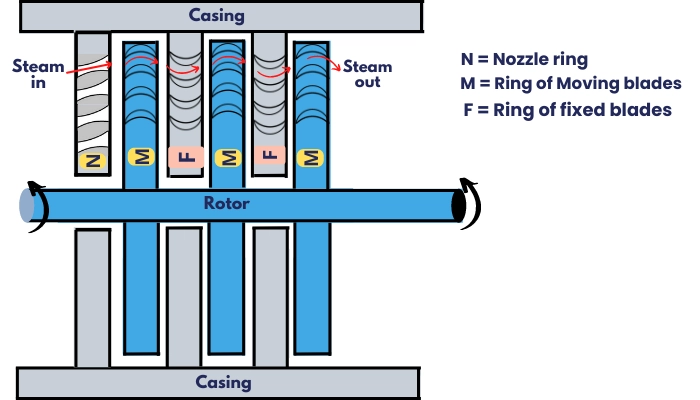

The velocity compounded steam turbine consists of the following components:-

- A single set of the nozzle at the first stage.

- Sets of moving blades mounted on a rotor.

- Sets of fixed blades mounted on the casing.

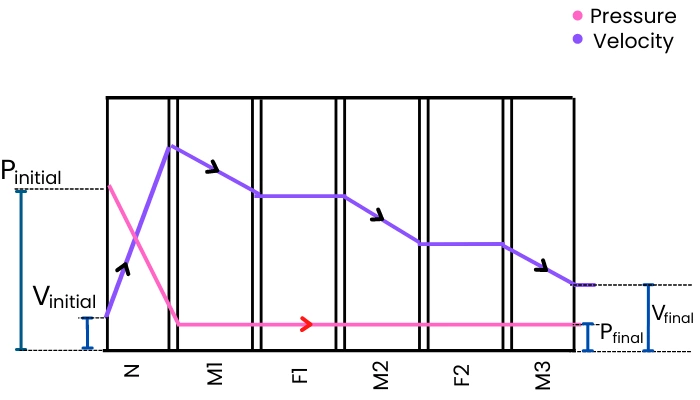

The below figure shows the variation of the pressure and velocity during the expansion of steam in a velocity compounded steam turbine.

In the above figure, N represents a set of nozzles, (M1, M2, M3) represents a set of moving blades, and (F1, F2) represents a set of fixed blades.

The velocity compounded turbine works as follows:-

1] The high-pressure steam from the boiler is expanded into the set of nozzles (N). While passing through the nozzles, the total pressure of the steam is dropped to increase the kinetic energy.

Thus in the nozzle, the pressure of the steam gets decreases and the velocity gets increases.

2] Now this high-velocity steam is passed over the 1ˢᵗ set of moving blades (M1). At the 1ˢᵗ set of moving blades, some part of the velocity of steam is utilized to rotate the moving blades.

3] After that steam is passed over the set of fixed blades (F1). The fixed blades change the direction of the steam so that the steam can easily glide on 2ⁿᵈ set of moving blades.

4] After leaving the set of fixed blades (F1), the steam is passed over the 2ⁿᵈ set of moving blades (M2). At this stage, the moving blades utilize some part of velocity to rotate the rotor, and then steam is further sent to the next stage.

5] In this manner, the velocity of the steam gets dropped in step by step manner in a number of stages until it reaches the exhaust velocity.

2] Pressure compounding of steam turbine:

It is a method of compounding the steam turbine in which the total pressure drop is divided into a number of stages.

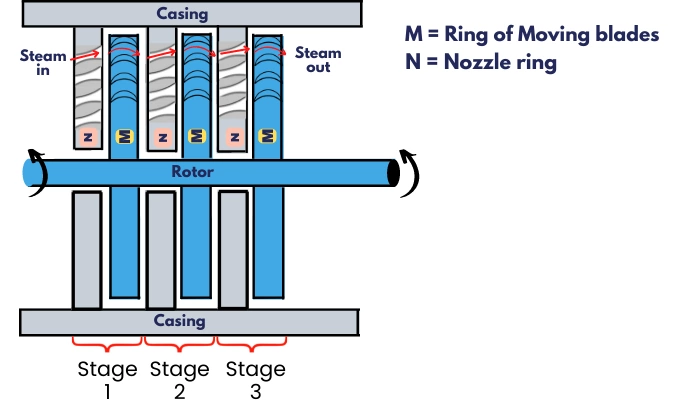

The pressure compounded steam turbine consists of the following components:-

- Sets of nozzles rings

- Sets of moving blades

The below figure shows the arrangement of the pressure compounded steam turbine.

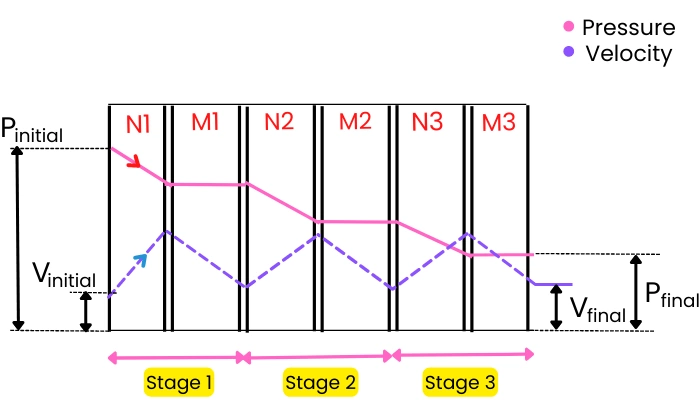

The pressure and velocity variation for the pressure compounded steam turbine is shown below:-

In the above figure, M1, M2, M3 represent the set of moving blades, and N1, N2, N3 represent the set of nozzles.

The pressure compounded turbine works as follows:-

1] After entering the steam into the turbine, the high-pressure steam gets partly expanded into the 1ˢᵗ set of nozzles (N1), thus the pressure of steam gets decreases and the velocity of steam gets increases.

2] Further this high-velocity steam is passed over the first set of moving blades (M1) where the kinetic energy of the steam is utilized to rotate the moving blades.

3] After escaping from the first set of moving blades (M1), the velocity of the steam gets reduced.

4] Now this low velocity and high-pressure steam is passed over the 2nd set of the nozzle (N2). Thus the pressure of steam is again partly reduced to raise the velocity of steam.

5] Again this high-velocity steam is passed over the 2ⁿᵈ set of moving blades (M2) to give momentum to the moving blades to rotate the rotor.

6] In this way, the pressure of the steam is partly utilized in each stage until the pressure of steam reduces to the condenser pressure.

3] Pressure – Velocity compounding of steam turbine:

This method of compounding steam turbine has both advantages of pressure compounding and velocity compounding. In other words, it is the combination of pressure compounding and velocity compounding.

The pressure drop in this turbine is done in a number of stages and each stage in this turbine acts like a velocity compounded turbine.

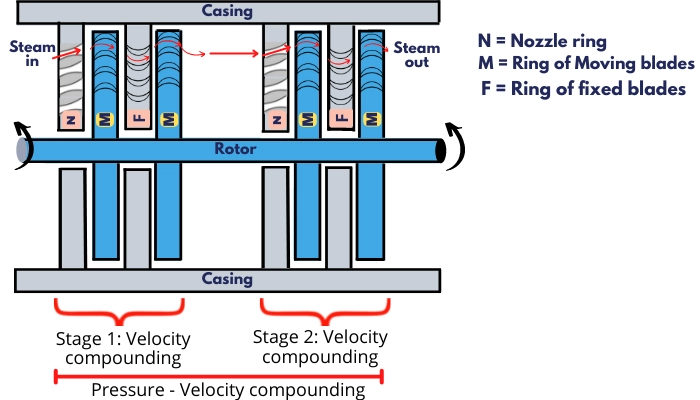

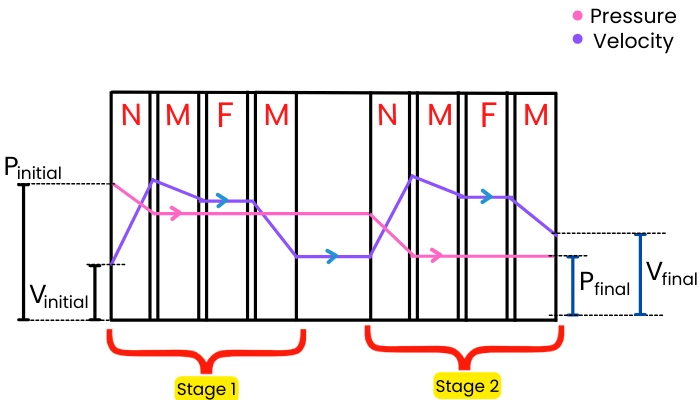

The schematic diagram of the pressure velocity compounded steam turbine is shown below:-

As shown in the above figure, each stage in this turbine acts as a velocity compounded turbine and all stages together act as a pressure compounded turbine.

Each stage in this turbine consists of the following components:-

- Set of a nozzle

- Sets of moving blades

- Sets of fixed blades.

The variation of pressure and velocity of steam in this turbine is shown below:-

The pressure-velocity compounded turbine works as follows:-

1] The high-pressure steam enters into the set of nozzles (N) of the first stage. Here the high pressure of steam is partly dropped to raise the velocity of steam.

Now, this high-velocity steam is passed over a set of moving blades (M). Here velocity of steam is partly reduced to rotate the moving blades.

After getting velocity partly reduced, the steam is passed over the fixed blades (F) where it is redirected over the next set of moving blades.

In this manner, the steam is alternately passed over fixed blades and moving blades until the velocity of steam is completely reduced to a minimum.

2] After leaving the first stage, the steam is passed over a set of nozzles of 2ⁿᵈ stage where the pressure of steam is again reduced to raise the velocity.

After getting high velocity, the steam is passed through the set of moving blades and fixed blades where the velocity of steam is partly utilized in each set of moving blades to rotate the rotor.

In this manner, the pressure of the steam is partly utilized in each stage of the turbine.

Advantages of compounding of steam turbine:

The advantages of compounding of a steam turbine are discussed below:-

- The compounding helps to reduce the speed of the rotor.

- It reduces the vibrations in the turbine.

- The compounded steam turbine requires less floor area.

- The power loss in a single-stage turbine is reduced by using compounded steam turbine.

- Increases the life of the components of the steam turbine.

FAQs:

-

What is compounding in impulse steam turbine?

Compounding is the method of reducing the rotor speed by expanding the steam in multiple stages of the turbine that are mounted on the same rotor.

-

What are the advantages of compounding steam turbines?

The compounding of the steam turbines helps to reduce the speed of the rotor as well as helps to extract the maximum energy from the steam to increase the power output.

-

What are the types of compounding of steam turbine?

The different types of compounding of steam turbines are as follows:

1] Velocity compounding

2] Pressure compounding

3] Pressure – velocity compounding