Hello friends, Today we will discuss the failure in cutting tool during machining processes.

Contents:

Cutting tool failure:

The cutting tool is said to be failed when it becomes unable to perform satisfactory cutting operation. The tool failure can occur suddenly by fracture of cutting edges or wear slowly.

The failure of the cutting tool can be identified by the following observations:

- Breakage in tool tip

- Fracture at cutting edges

- Rise in vibration & cutting forces

- Wear exceeds over limits

- High power consumption

- Higher noise & vibration

- Poor surface finish

- Abnormal chip formation

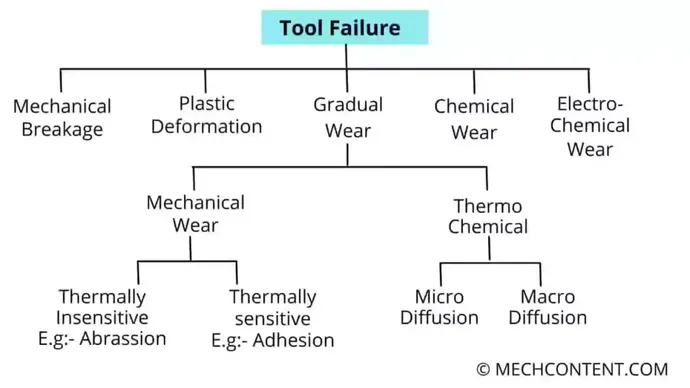

Types of Cutting tool failure:

Following are the different failures occurs in cutting tools:

A] Mechanical Breakage:

Mechanical breakage occurs due to excessive forces & shocks, which directly damage cutting edges of the tool.

B] Plastic deformation:

Plastic deformation occurs due to high stresses & higher temperature. Hence, the tool material looses its hardness & plastic deformation occurs.

C] Gradual wear:

Wear failure occurs due to gradual wearing of flank & rake surface of tool. It can be further classified as:

i] Mechanical wear:

The mechanical wear also has two types.

The mechanical wear which occurs due to change in thermal conditions are known as thermally sensitive wear. E.g. Adhesion, fracturing.

And the mechanical failure which is not depended on change in thermal conditions are known as thermally insensitive wear, E.g. Abrasive, Chipping.

ii] Thermo-Chemical wear:

It occurs when two material got mutual affinity or mutual solubility. The constituent material of tool starts diffusing from tool to chips of work-piece.

If the diffusion occurs in bulk, then the diffusion is macro diffusion. If the diffusion is done atom by atom then it is known as micro diffusion. The rate of diffusion wear increases with increase in temperature.

D] Chemical wear:

It occurs when tool material is not chemically inert. If the tool material has chemical affinity with cutting fluid or working environmental conditions, then this type of wear occurs.

It can be eliminated by choosing proper tool material, or cutting fluid, hence increasing the tool’s life.

E] Electro-chemical wear:

When at the tool chip interface the heat is generated, this causes generation of electric current by thermocouple effect.

FAQ:

-

When you can say the cutting tool is to be failed?

Due to some following causes, we can say that cutting tool is to be failed:-

High power consumption than normal

Increased noise and vibration.

Surface finish becomes poor.

Increase in cutting forces.

Damaged tool tip.