The governors are used to maintain the mean speed of the engine. Here we are discussing the Hartnell governor, which was invented in 1875 by the scientist Hartnell.

Contents:

What is Hartnell Governor?

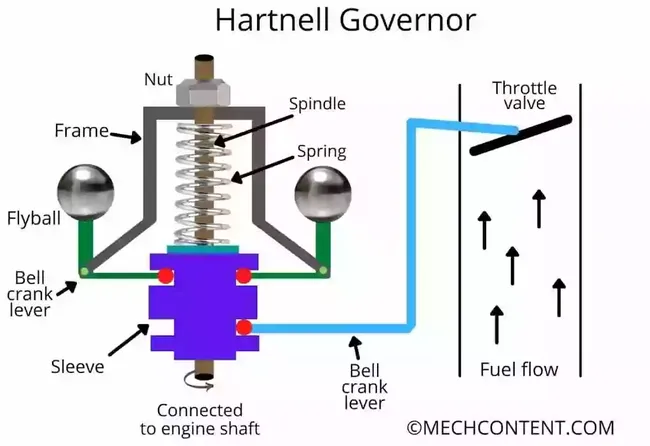

Hartnell governor is a type of spring-loaded centrifugal governor. In Hartnell governor, the downward force on the sleeve is applied by spring.

This downward force can be adjusted by applying compression to the spring by adjusting the nut on the frame (see below figure).

The spring in this governor performs the same role as the dead weight used in the porter governor.

It consists of a bell crank lever, pivoted to the frame. It has a flyball mounted on a vertical arm and a horizontal arm is inserted into the slot of the sleeve by means of a roller.

In this, the mean speed of the engine is adjusted by adjusting the load on the spring. While in the case of dead-weight-loaded governors, it is not possible to adjust the mean speed

Because of the adjustable spring load, the size of flyballs is also less compared to another governor. Due to this, it is smaller in size as compared to other governors.

Also, as it is spring-loaded, it doesn’t require gravitational force to return to the initial position after lowering of speed. The spring forces it to return to its initial state. Hence, it is possible to mount it in an inclined or horizontal position.

It uses rollers at the sleeve surface, hence it has less frictional resistance.

Construction:

It is consists of the following parts:

1] Bell crank lever: The bell crank lever is pivoted to the frame. It has a flyball mounted on the vertical arm and the horizontal arm is connected to the sleeve.

2] Flyball or Governor ball: These are mounted onto the vertical arm of the bell crank lever. The weight of flyballs is comparatively lower than other governors.

3] Spring & Nut: Spring is a helical coil spring that is enclosed into the frame. It is mounted onto the spindle between the frame & sleeve. It is used to apply downward force onto the sleeve.

The nut is mounted onto the frame to adjust the compression of the spring to apply load on the sleeve.

The downward force on the sleeve can be adjusted, by adjusting the nut on the frame. This helps in changing the mean speed of the governor.

4] Sleeve: It is the basic component of the governor that is mounted on the spindle of the governor.

The movement of the sleeve is used to adjust the supply of fuel to the engine. The horizontal arm of the bell crank lever is connected to the sleeve by means of a roller.

5] Frame: The frame is used to holds bell crank levers & spring.

Hartnell governor working:

Case 1: When the load on the engine increases

When the load on the engine increases, the speed of the engine decreases.

Because of the decrease in engine speed, centrifugal force on flyball decreases and flyballs moves inside. Hence, load on the spring decreases and the length of the spring extends.

It results in lowering of the sleeve on the spindle. Thus, the supply of fuel to the engine increases, and the speed of the engine increases to the mean speed.

Case 2: When the load on the engine decreases

When the load on the engine decreases, the speed of the engine increases.

Because of the increase in engine speed, centrifugal force on flyball increases and flyballs moves outside. Hence, load on the spring increases and the length of the spring decreases.

It results in the upward movement of the sleeve on the spindle, hence the supply of fuel to the engine decreases, and the speed of the engine decreases to the mean speed.