What is Laser beam machining (LBM)?

Laser beam machining is the machining process in which the heat energy produced by the laser is used to remove the material from the workpiece surface.

But what is laser?

Laser is the amplification of light. The full form of laser is Light amplification by stimulated emission of radiation. It means the laser is the photons that are emitted from the energized electrons.

It is the type of non conventional machining process commonly used for brittle material.

Continue reading further to know its working principle, construction, working, advantages, and much more.

Contents:

Working principle:

Laser beam machining works on laser produced by the ruby crystal for the machining.

When the laser falls on the work-piece surface, the heat energy produced by this laser melts and vaporizes the material on the surface.

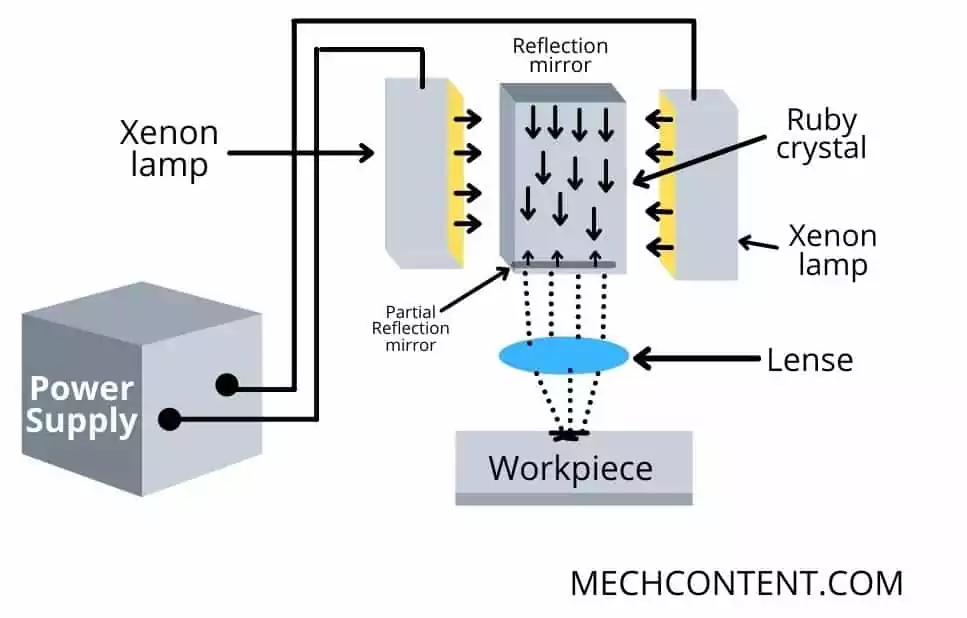

The below figure shows the apparatus for the laser beam machining.

Construction:

This setup mainly consists of the following components:

1) Power supply: The power supply supplies the high voltage power (Around 1Kw-10Kw) to the xenon lamps to produce light.

2) Xenon lamps:- Xenon lamps take power from the power source and produce light. This light from the xenon lamp energizes the electrons of the crystal atoms.

3) Ruby crystal:- The ruby crystal produces the laser by absorbing the light from xenon lamps. This crystal consists of a large number of atoms. When light from xenon lamps falls on the crystal, electrons in the crystal get energized and produce photons or light energy.

4) Focus Lens:- In the laser beam machining process, the lens is used to focus all light energy or photons that come from the ruby crystal on the workpiece.

Working of Laser beam machining:

As the high-voltage power source turns on, Xenon lamps start producing light. This light from the xenon lamps is absorbed by the electrons in the crystal atoms.

Due to light, electrons get energized to a high energy level from the ground state and then start emitting more photons to come again to their ground state.

The upper reflected mirror reflects all these photons to the crystal, and the lower partial reflected mirror reflects some photons and releases remaining photons throughout itself.

The photons from the ruby crystal fall on the lens. The focus lens focuses all the photons and produces a laser on the workpiece.

When this laser falls on the workpiece, due to the laser heat, the workpiece surface melts and vaporizes.

Hence, in such a way, laser beam machining is used for the machining.

Advantages of LBM:

The advantages of this machining process are as follows:-

- A very good surface finish can be obtained.

- No tool wear.

- Can machine complex shapes.

- No direct contact between the tool and workpiece.

- High accuracy of machining.

Disadvantages of LBM:

The disadvantages of this machining are as follows:-

- It has a limitation of thin sheets, which means it can’t drill deep holes.

- Very less material removal rate

- Xenon lamp has less life period

Applications:

- It is used for drilling, and cutting purposes in automobile, aerospace, and many other industries.

- It is used in drilling small-sized holes.

Difference between electron beam machining and laser beam machining:

| Sr. No. | Electron beam machining | Laser beam machining |

|---|---|---|

| 1 | It uses heat energy produced by high velocity, focused electron beam for the machining. | It uses heat energy produced by the laser beam for machining. |

| 2 | An electron gun is the source of the electron beam. | Xenon lamp is the source of the laser beam. |

| 3 | The material removal rate is low. | Comparatively, high material removal rate. |

| 4 | X-rays are generated during machining, which are dangerous for the operator. | X-rays are not generates during machining. |

| 5 | This machining process is carried out in a vacuum chamber since if electrons comes in contact with particles in atmospheric air then electron will loose their energy. | No need for a vacuum chamber for machining. |

| 6 | High-skilled operators are required. | Less skilled operators can handle it. |

Read also: