What is Multi plate clutch?

Multi plate Clutch is one of the Friction type plate clutches.

In this clutch, multiple friction plates are used as compared to a single-plate clutch.

Due to the presence of multiple plates, it has a higher capacity of torque transmission as compared to a Single plate clutch, because due to the presence of multiple plates, friction surface increases.

Contents:

Multi plate clutch parts/components:

Parts of Multi plate clutch are as follows:-

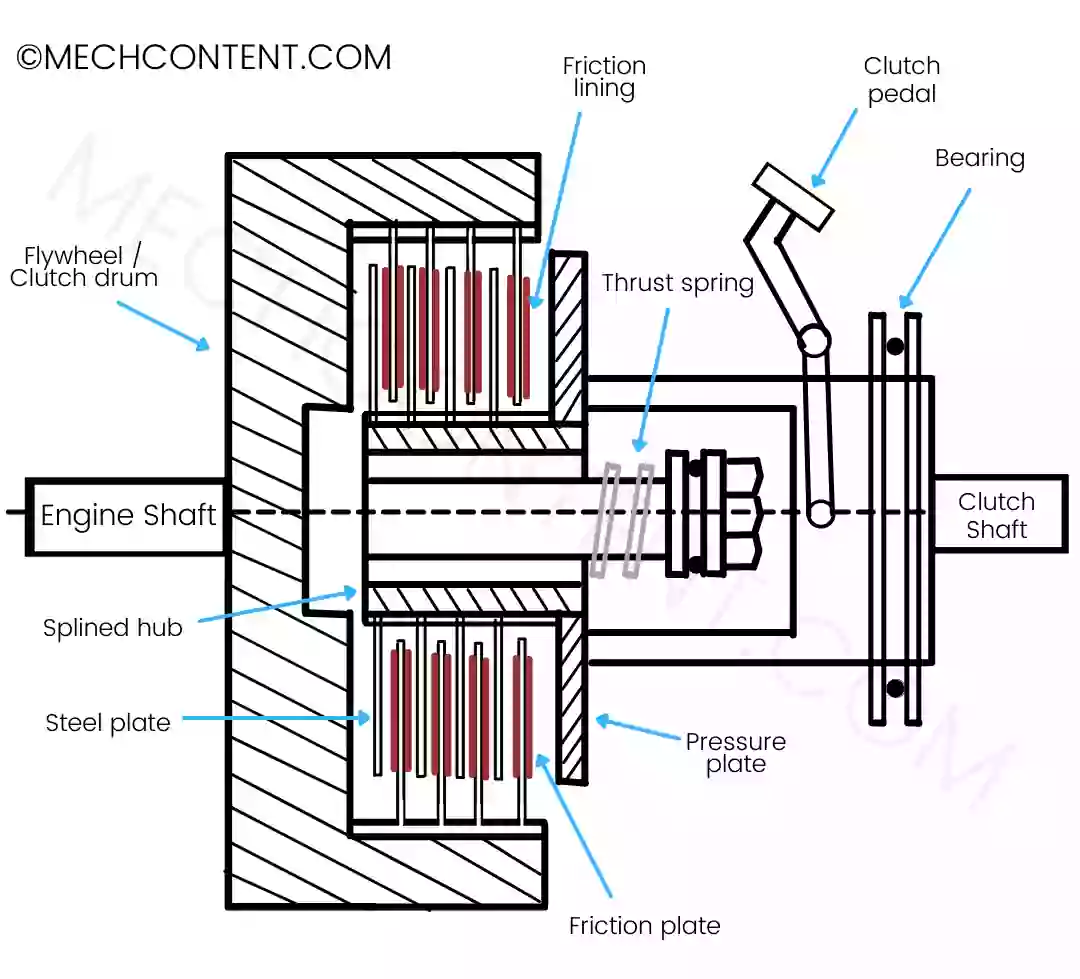

1] Clutch drum:-

Clutch drum is connected to the engine shaft. It rotates continuously as the engine shaft rotate. The clutch drum has slots on its circumference so that the externally threaded friction plates can slide into the clutch drum.

2] Splined inner hub:-

The hub is connected to the gearbox shaft. It rotates with the speed of the gearbox. The inner hub is splined so that the internally toothed steel plates can slide on it.

3] Clutch pack:-

The clutch pack consists of two types of round plates: Friction discs and steel plates.

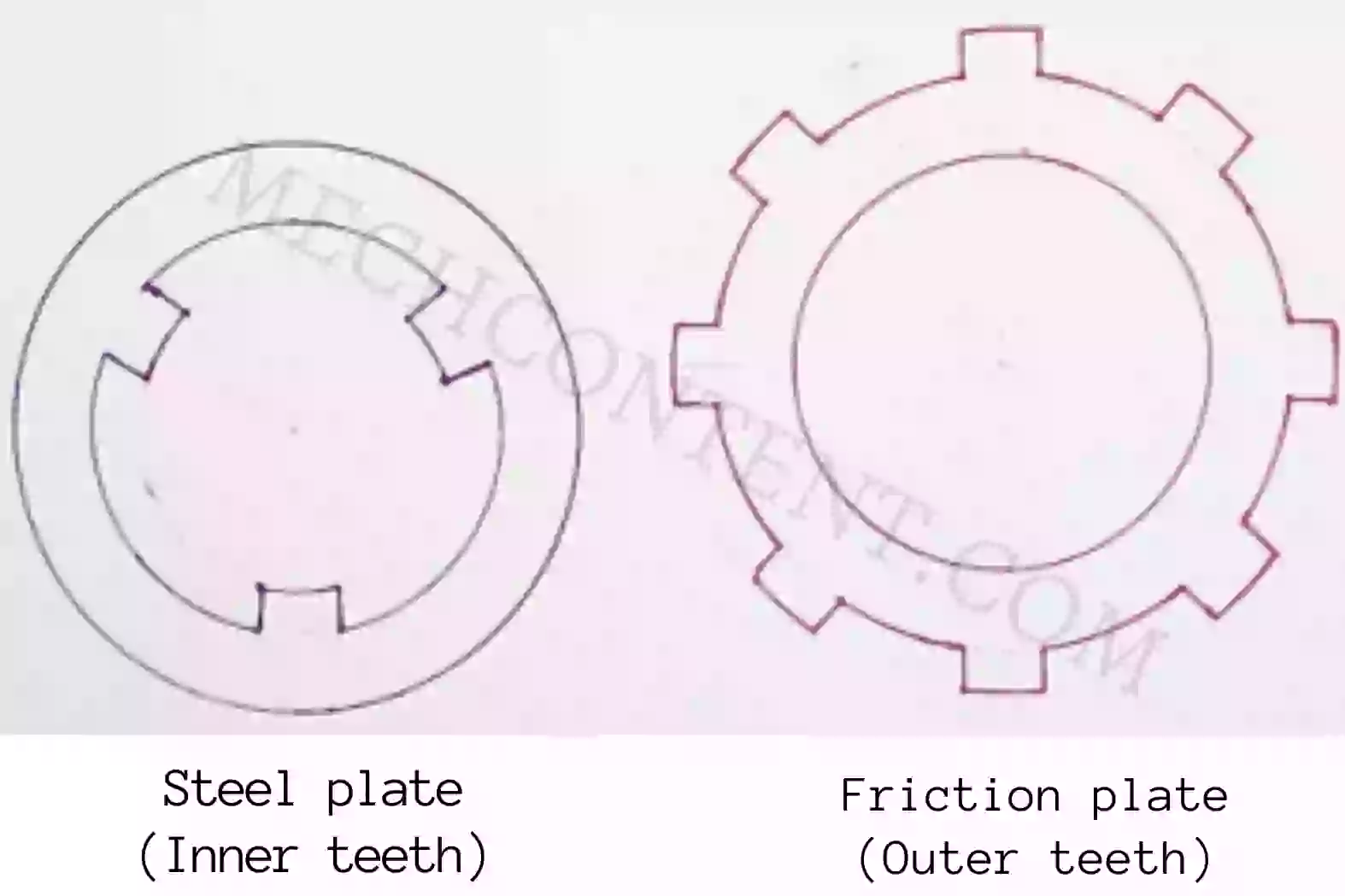

4] Friction disc:-

It is also known as friction plate. It has asbestos lining for frictional contact. The friction plates are externally toothed and these plates are mounted into the clutch drum.

The friction plates can easily slide into the slots of clutch drum.

5] Steel plate:-

These plates are internally toothed and mounted on inner splined hub. These plates are rotates with the speed of the gearbox.

6] Pressure plate:-

Pressure plate is generally observed in all types of clutches.

The main aim of pressure plate is to apply pressure on to the friction plates so that the friction plates on clutch bucket and steel plates on inner hub are hold firmly together and start to rotate as single unit.

The pressure plate is mounted on inner hub with the use of sleeves. The pressure plate can easily move on sleeve for engagement and disengagement. The motion of pressure plate is operated by pedal and thrust spring.

7] Thrust spring:-

The aim of the thrust spring is to keep the friction plate and steel plate in firm contact so that they can rotate together.

A thrust spring is attached behind of pressure plate.

8] Clutch pedal:-

This is the part of the clutch which is operated by the operator for engaging and disengaging the clutch.

The aim of the clutch pedal is to operate the movement of the pressure plate hence it helps in the engagement and disengagement of the clutch.

Construction:

1) The clutch drum is connected to the engine shaft.

2) Splined inner hub is connected to the gearbox shaft.

3) The externally toothed friction plates are mounted into the slots of the clutch drum and the friction plate can easily slide into the slots of the clutch drum.

4) The internal toothed steel plates are mounted on splined inner hub and can easily slide on it.

5) As shown in the above figure, both types of plates are arranged in one by one manner.

6) All the plates are pressed together by means of a pressure plate.

7) Thrust spring is mounted behind of pressure plate which pushes the pressure plate to hold the friction plates together.

8) The pedal is used for the movement of the pressure plate for engagement and disengagement.

Multi plate clutch working:

The working includes the engagement and disengagement of the clutch which is discussed below:-

Engagement of clutch:-

1) The clutch is generally in engaged condition.

2) The friction plates are mounted into the clutch drum which is further connected to engine shaft.

3) The steel plates are mounted on inner hub which is connected to gearbox shaft.

4) Hence to transmit power from engine shaft to gearbox shaft it is necessary to hold friction plate and steel plate together. This is done by a pressure plate. The pressure plate holds both types of plates together by means of thrust spring.

5) Hence friction plate and steel plates rotate together as a single unit and transfer power from engine to gearbox.

Disengagement of clutch:-

1) For Disengagement of clutch, an operator has to press clutch pedal.

2) As we press the clutch pedal, the pressure plate is moved in backward direction.

3) It results in removal of pressure on set of friction plate and steel plate.

4) Now the frictional contact between these two plates is loosen.

5) lt breaks the contact between engine shaft and gearbox shaft.

6) This condition is known as disengaged condition.

7) Now if we release the pedal again then the thrust spring again pushes the pressure plate on friction plates which will result in the engagement of the clutch.

Advantages:

The multi plate clutch has the following advantages:-

- Less effort requires to operate this clutch.

- It is compact in size and hence requires less space.

- It has a high power transmission capacity.

Disadvantages:

The multi plate clutch has the following disadvantages:-

- It uses many numbers of plates hence more heat generates in this type of clutch.

- It is heavier in weight.

- It is costlier.

Applications:

The multi plate has wide applications such as follows:-

- Motorcycle

- Cars

- Scooter

Multi plate clutch formula:

Maximum torque transmitted by multi plate clutch for uniform pressure:-

`T=n \times \frac{2}{3} \times \mu \times W[ \frac{ ( R_{1}^{3}-R_{2}^{3} )}{ ( R_{1}^{2}-R_{2}^{2} )} ]`

Where,

n = Number of plates

W = Axial thrust on plates

μ = Coefficient of friction

R2 = Inner surface of the friction surface

R1 = Outer radius of friction surface

Maximum torque transmitted by multi plate clutch by uniform wear theory:-

`T= n \times \frac{1}{2} \times \mu \times W(R_{1}+R_{2})`

Difference between single plate clutch and a multi plate clutch:

| Sr. No. | Single plate clutch | Multi plate clutch |

|---|---|---|

| 1 | This type of clutch is made up of a single friction plate. | This type of clutch is made up of multiple friction plates. |

| 2 | It takes more space. | It is compact in size hence it takes less space. |

| 3 | It does not allow smooth engagement. | It allows smooth as well as gradual engagement. |

| 4 | It has less frictional loss due to the use of a single plate. | It has more frictional loss due to the use of a number of plates. |

| 5 | It has applications in Jeep and Truck. | It has applications in motorcycles and scooters. |

FAQs:

-

What are the advantages of a multi plate clutch?

The multi plate clutch has the advantage that it is compact in size.

-

What are the disadvantages of a multi plate clutch?

The multi plate clutch has the disadvantage that it is costly and heavier in weight.

Read also these articles: