What is Quick return mechanism?

In Quick return mechanism, the movement of the reverse stroke is faster than the forward stroke. The mechanism is generally used in applications where the velocity of the tool at return stroke is not considerable.

Therefore, the faster movement of the ram, during reverse stroke helps to reduce the total machining time.

It is the inversion of a single slider crank chain. This mechanism has a different velocity of ram in the forward stroke and in reversed stroke.

Continue reading to know about its construction, principle, and applications.

Contents:

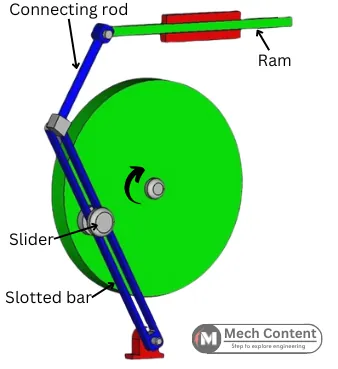

Components of Quick return mechanism:

The Quick return mechanism consist of the following key components:

1] Crank: The crank is connected to the pinion wheel or motor and rotates with a uniform angular velocity.

2] Slider & Slotted bar: The slider is pivoted at the end of the crank. This slider moves freely into the slotter bar. This component is used to convert the circular motion of the crank into the oscillating motion of the slotted bar.

3] Connecting rod: The purpose of the connecting rod is to convert the oscillating motion of the slotted bar into the reciprocating motion.

4] Ram: The ram reciprocates in the horizontal direction along the line of stroke.

Construction of Quick return mechanism:

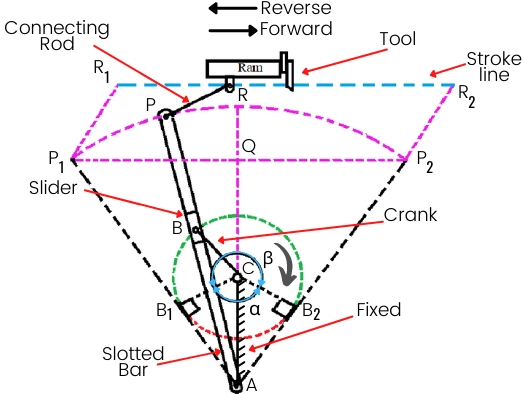

As shown in the above figure, the link ‘AC’ is fixed. The crank ‘BC’ is pivoted at the end ‘C’ and rotates with constant angular velocity.

The slider ‘B’ is connected at the end of the crank & it rotates along with crank ‘BC’.

The slotted lever ‘AP’ is pivoted at the end ‘A’. As the slider ‘B’ reciprocates in a slotted bar, the slotted bar performs oscillatory motion in the circular arc from ‘P1’ to ‘P2’.

The one end of connecting rod ‘PR’ is connected to the slotted bar and another end is connected to the ram ‘R’. The ram ‘R’ reciprocates from ‘R1’ to ‘R2’.

Working principle of quick return mechanism:

The working of the Quick return mechanism consists of two strokes: Forward and Reverse stroke.

Forward stroke:

For forward stroke, the crank ‘B’ has to move from point ‘B1’ to ‘B2’ in a clockwise direction. In above figure, the forward path of crank ‘B’ is denoted by a green dotted line.

At the same instant, the end of the slotted bar moves from ‘P1’ to ‘P2’ in clockwise direction. And the ram ‘R’ moves from position ‘R1’ to ‘R2’ in forward direction.

Reverse stroke:

For return stroke, the slider ‘B’ moves from position ‘B2’ to ‘B1’ in a clockwise direction. In above figure, the return path for crank ‘B’ is denoted by a red dotted line.

At the same instant, the end ‘P’ of the slotted bar moves from position ‘P2’ to ‘P1’ in an anticlockwise direction. And the ram ‘R’ moves from ‘R2’ to ‘R1’ in the backward direction.

Relation between time for forward stroke and return stroke:

1] For the completion of the forward stroke of ram from ‘R1’ to ‘R2’, the slider ‘B’ has to move from position ‘B1’ to ‘B2’ with an angle of ‘β’.

Therefore, we can say that,

Time for the forward stroke = Time to cover angle β by crank

2] For the completion of the return stroke of ram from ‘R2’ to ‘R1’, the slider ‘B’ has to move from ‘B2’ to ‘B1’ with angle ‘α’.

Therefore, we can say that,

Time for the return stroke = Time to cover angle α for the crank.

But from the above figure, as β > α and the crank has constant angular velocity.

Therefore, it can conclude that

Time for forward stroke > Time for return stroke

Now the relation between time for the forward stroke and time for return stroke is given by,

`\frac{\text{Time for forward stroke}}{\text{Time for return stroke}}=\frac{\beta }{\alpha }=\frac{\beta }{360-\beta }`

Quick return mechanism advantages:

The advantages of the Quick return mechanism are as follows:

- Rapid movement while return stroke.

- It is useful for conversion of rotary motion in reciprocating motion.

- The faster return stroke helps to minimize total working time of machines in which material removal is carried out only in forward stroke.

Quick return mechanism applications:

Some of the applications of the this mechanism are as follows:

- Shaper machine

- Slotting machine

- Mechanical actuators

- Rotary internal combustion engine

- Mechanical cutter

- Air compressors

- Power saws

FAQ’s:

-

Which machine uses quick return mechanism?

The quick return mechanism is used in the following machine’s:

Shaper machine, slotting machine, mechanical actuators, mechanical cutter, air compressor, power saw, etc. -

Why is the return stroke faster in quick return mechanism?

In the case of return stroke, for the movement of slotted bar the crank has to complete minimum angular displacement in comparison with forward stroke, therefore the return stroke is faster in quick return mechanism.

If you have any doubts then please put them in the below comment box. We will answer you as soon as possible. So if you found this article helpful don’t forget to share it with buddies through social networks.

Read also:

Whitworth quick return mechanism

References: