What is rope brake dynamometer?

The rope brake dynamometer is the device that measures the power of the engine shaft by applying frictional resistance to the motion of the shaft by use of rope.

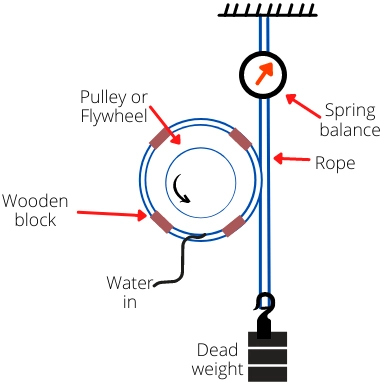

It simply consists of pulley and rope arrangement along with the spring balance to measure the tension in ropes.

The rope brake dynamometer measures the torque required to stop the shaft of the prime mover.

By using the torque and speed of the shaft we can calculate the power of the shaft of the prime mover.

Contents:

Working principle:

The rope dynamometer measures the power by absorbing all the energy of the engine or prime mover by means of frictional resistance.

Therefore, the shaft power is given by,

Shaft power = Frictional resistance

Parts of rope brake dynamometer:

The rope brake drum dynamometer consists of the following components:

1] Pulley or Flywheel: The pulley is mounted on the shaft of the prime mover whose power has to be measured.

2] Rope: The rope is wound over the circumference of the pulley. The rope generates frictional resistance to stop the brake drum.

One end of the rope is attached to the spring balance while another end is attached to the dead weight.

3] Wooden block: The wooden blocks are placed onto the rope to avoid the slip of the rope over the pulley.

4] Dead weight: The dead weight is mounted at the bottom of the rope that assures the tightening of the rope over the pulley.

5] Spring balance: The spring balance is connected to the upper end of the rope that is used to measure the tension in the rope.

6] Cooling water: The heat generated by the friction between rope and pulley is carried away by the flow of cooling water.

Working of rope brake dynamometer:

Following is the procedure to measure brake power using a rope brake dynamometer.

1] Connect the pulley of the rope brake dynamometer to the shaft of the engine or any prime mover.

2] Start the prime mover or the engine and check the engine rotates at a constant speed.

3] Measure the speed of the pulley (`\omega`) of the dynamometer by using a tachometer.

4] Gradually apply dead weights (W) at the end of the rope until the brake drum stops rotating.

5] Measure the dead weight (W) and the tension (t) displayed on the spring balance.

6] Now by using the equation for power calculation, calculate the power of the engine or any prime mover.

Rope brake dynamometer formula:

The brake power of the shaft of the prime mover is calculated by the using following formula:

`P = T \times \omega `

Where the frictional torque (T) and angular speed (`\omega`) is given by,

Frictional torque, (T) = (W – t) .`\frac{D+d}{2}`

Angular speed `\omega =\frac{2\pi N}{60}`

Where,

W = Dead weight (N or lb)

t = Tension in balance (N or lb)

D = Pulley diameter (m or ft)

d = Rope diameter (m or ft)

N = Engine speed (RPM)

Therefore, power of engine shaft is given by,

P = (W – t) `\times \frac{D+d}{2}\times \frac{2\pi N}{60}`

If the rope diameter is much less than pulley diameter,

P = (W – t) `\times \frac{D}{2}\times \frac{2\pi N}{60}`

P = `(W – t) \times ` R`\times \frac{2\pi N}{60}`

Advantages and disadvantages of rope brake dynamometer:

Advantages:

- It is easy to construct the rope brake dynamometer.

- It is easy to measure the power using a rope brake dynamometer.

- A less expensive method to measure power.

Disadvantages:

- Loss of power for the measurement.

- It does not measure the accurate power.

- It requires a coolant supply to carry away the heat generated.

Rope brake dynamometer uses:

The rope brake dynamometer is used to measure the power of,

- Engine

- Motor