What is Stereo-Lithography process (SLA)?

The stereolithography process is one of the Rapid Prototyping processes in which liquid polymer is used as material for layer-by-layer 3-D part building. It is done with the help of a Laser for the solidification of liquid resin.

Contents:

Stereolithography working principle:

In the Stereolithography process, As per the action of the laser beam, a layer of liquid resin gets solidified on the platform. This solidification of the liquid layer is used to build the part.

Construction:

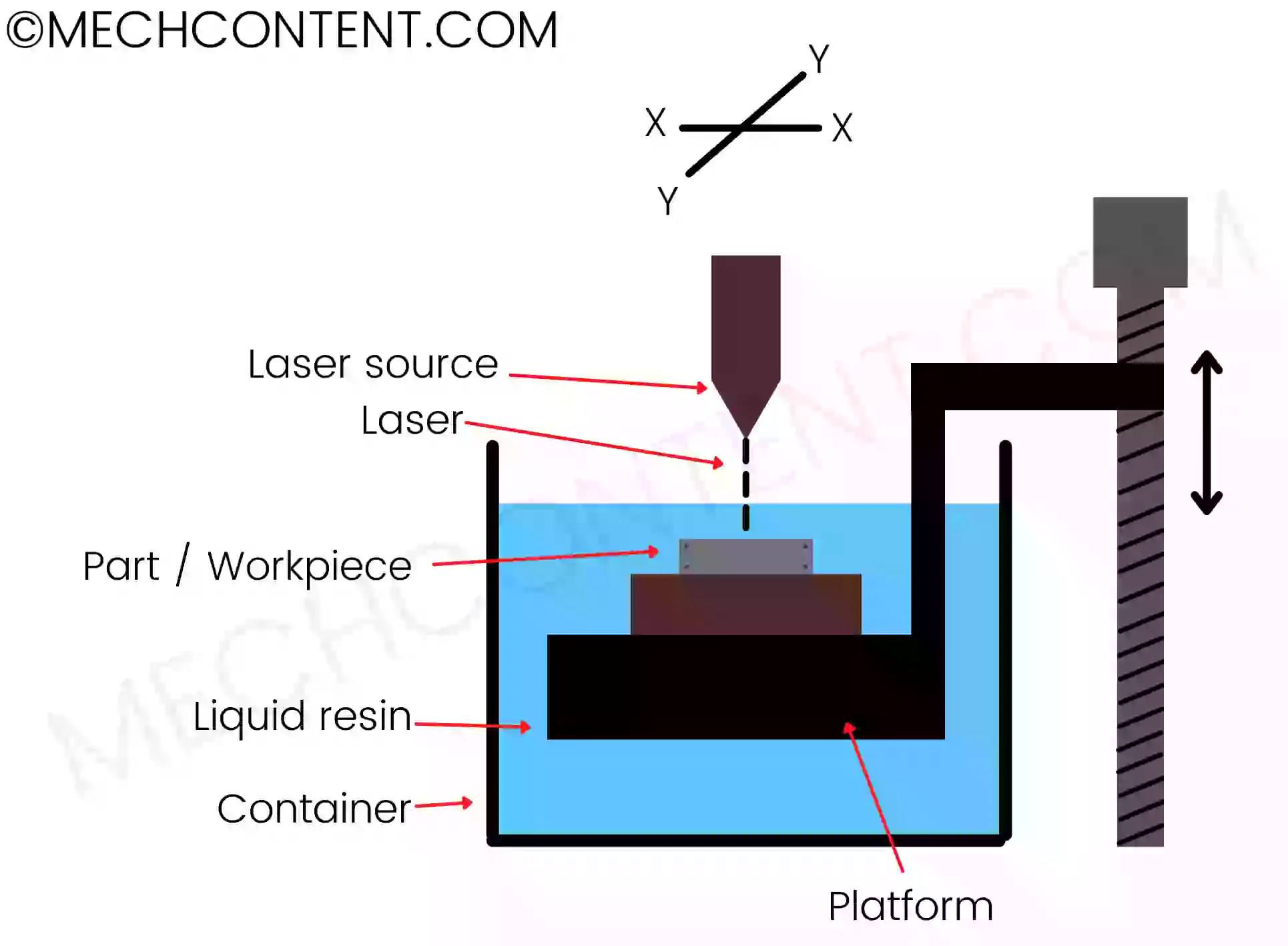

Stereo-Lithography machine consists of the following components:-

1) Laser source: A laser source is used to supply a laser to solidify liquid resin to build the part in layers.

2) Container: The container is filled with the liquid resin, When the laser falls on the liquid resin, the liquid resin gets solidified.

3) Platform:- Platform helps in the part building. The platform can move in an upward and downward direction. Therefore during part building, the Platform moves downwards so new layers of liquid resin get solidified on the old solidified layer.

Stereolithography process working:

When the laser source gets on, the Laser falls on the liquid resin above the platform.

Hence due to the laser, the Liquid resin layer above the platform gets solidified.

Therefore Platform moves downwards and a new solidified layer of liquids forms on the old solidified layer. In such a way, the platform moves downwards, and the Product builds on the platform in layers.

Advantages and Disadvantages:

Advantages:-

- Less material waste

- Part with high precision as well as smooth finish can be produced.

Disadvantages:-

- The process requires more time.

- High initial investment.