Superheated steam is used in turbines because, in comparison with saturated steam, superheated steam gives higher power output, increases efficiency, and increases the life of the steam turbine.

Before we get into it, let’s take a quick look at superheated steam.

Superheated steam:

At particular pressure, when the temperature of the steam rises above the saturation temperature then the steam is said to be lies in the superheated region.

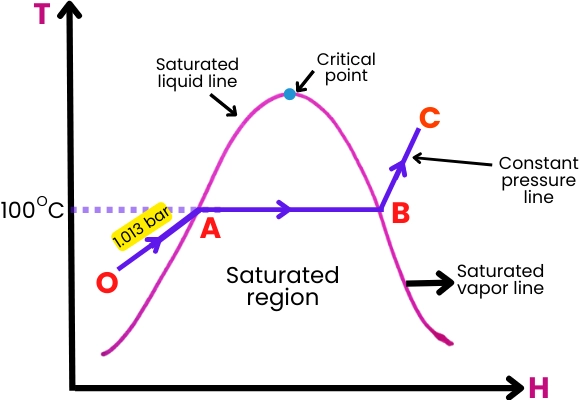

Example: At a pressure of 1.013 bar, the saturation temperature of the steam is 100 °C.

The profile O-A-B-C shows the formation of superheated steam at a constant pressure of 1.013 bar.

As shown in the above figure, at point B, the steam becomes saturated, and because of further heating, the temperature of the steam rises ahead of the saturation temperature. Thus, we can say that the steam enters into the superheated region. The profile BC in the above figure shows the superheating of steam at a pressure of 1.013 bar.

Why is superheated steam used in turbines?

Following are the reasons behind the use of superheated steam in steam turbines:

1] Turbine output increases:

The superheated steam can expand up to a higher extent without entering into the saturated region.

The use of superheated steam in the turbine increases the total pressure drop across the turbine which increases the kinetic energy gained by the moving steam. This increased kinetic energy increases the output work of the steam turbine.

Thus, by use of superheated steam, the turbine can extract more energy from the steam and we can get increased power output from the turbine.

2] Suitable for multi staging:

The highly superheated steam can be expanded through multiple stages of the turbine without causing condensation of the steam.

Thus, the multiple stages of the steam turbine can extract maximum energy from the steam and convert it into the output work.

3] No harm to the turbine:

The use of highly superheated steam in the turbine lowers the chances of the formation of water droplets in the low-pressure region of the turbine.

Thus, no damage will occur to the turbine components by the water droplets. Thus, by use of superheated steam, the components of the turbine can last longer.

4] Turbine exhaust can be used as process steam:

The saturated steam at the exhaust of the turbine can be used as process steam for heating in process plants.

Thus because of these reasons, superheated steam is used in the turbine.

What happens if saturated steam is used to rotate the turbine?

The use of saturated steam in steam turbines can create the following difficulties:

1] Low power output:

The saturated steam can’t be expanded to a higher extent as more expansion leads to the condensation of steam.

Thus, we cannot utilize the maximum enthalpy of steam to rotate the turbine. Therefore, it will give less power output.

2] Not suitable for multi staging:

As condensation in saturated steam starts earlier, it is not suitable for expansion in multiple stages of the turbine.

3] Damage to the turbine components:

The saturated steam starts the condensation earlier during the expansion into the turbine. These condensed water droplets along with the high-speed steam impact on the intermediate and low-pressure blades with high kinetic energy. This causes erosion of the turbine blades.

Thus the saturated steam can’t be used to rotate the turbine since it accelerates the damage of turbine components.

Thanks for sharing your know how on Superheated Steam use. I enjoy reading topic on Physical Chemistry!