Are you looking for a perfect wrench for your work, but you are confused about how many types of wrenches are and which one should you choose? or want to study the different kinds of wrenches then take the help of this article which will answer your almost all questions regarding wrenches.

There are hundreds of types of wrenches that come in different shapes and sizes which are manufactured for performing specific applications. So as per different uses, there are different Wrenches like for instance to loosen pipes there is a pipe wrench that helps in completion of our work effectively and quickly.

So, In this article, we will introduce you to many types of wrenches as well as their applications.

By the end of this article, you will have learned ample knowledge about different types wrenches. so let’s start with our topic.

Wrenches types & their uses:

The different kinds of wrenches names are as follows:

- Open-ended wrench

- Box ended wrench

- Combination wrench

- Torque wrench

- Allen wrench

- Impact wrench

- Crowfoot wrench

- Lug wrench

- Drum key

- Dog bone wrench

- Tap wrench

- Strap wrench

- Torx key wrench

- Ratching wrench

- Bung wrench

- Die stockholder wrench

- Spoke wrench

- Tension wrench

- Bionic wrench

- Oil filter wrench

- Socket wrench

- Fan clutch wrench

- Pedal wrench

- Hammer or Striking wrench

- Armorer’s wrench

Adjustable wrenches types:

The detailed information, functions, uses, and pictures about the above all Wrenches are as follows:

1] Open-ended wrench:

The open-ended wrench is a commonly used wrench. It has open ends made up of two jaws which helps to hold the head of the fasteners firmly from two sides.

These wrenches come in many standard sizes and there are set of open-ended wrenches of different sizes available in the market. The open-ended wrench can be used for the hexagonal as well as square head fasteners.

In the case of a double open-ended wrench (as shown in above figure), both ends are open-ended, and in the such wrench, both ends have different size open ends.

2] Box ended wrench:

This wrench has a closed ring shape head and there are points on the inner circumference of the closed ring shape head which are helps to hold the fastener firmly.

Box-ended wrench holds the fastener head from all sides. It helps to hold or lock the corners of the fastener head, therefore it has fewer chances of rounding off the fastener head which happens in the case of an Open-ended wrench.

The box-ended wrenches can be used for hexagonal as well as square head fasteners.

The disadvantage of the box-ended wrench is that it can be used for loosening or tightening operations only if there is enough space around the fastener to install a wrench.

3] Combination wrench:

The combination wrench means a combo of two different wrenches which are Open-ended wrench and Close-ended wrench. So, we can take advantage of two different wrenches using this one wrench.

The benefit of using such a wrench is that closed-end helps in loosening the stuck bolt or tightening the bolt firmly while Open-end helps to quickly loosen or tighten the bolt.

4] Torque wrench:

The torque wrench is the wrench in which we can set how much torque should apply for a tightening of the fastener.

The preset value of torque helps from the over-tightening or improper tightening of the fastener.

There are six different types of torque wrench which are as follows:-

- Dial torque wrench

- Beam torque wrench

- Hyadraulic torque wrench

- Digital torque wrench

- Micrometer torque wrench

- Click torque wrech

Such a wrench plays a significant role in the automotive industry where during the assembly of vehicles, fastener requires to tighten up to the recommended value.

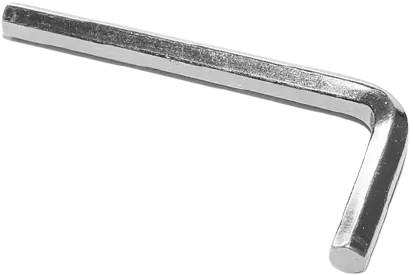

5] Allen wrench:

Allen wrench is the ‘L’ shaped tool having a hexagonal cross-section. It is also known as the Allen key or hex key.

Allen wrenches come in different sizes which helps us in using them for different applications.

As the Allen wrench has a hexagonal cross-section, it can only use for tightening or loosening of a fastener having hexagonal shaped recess on the head.

The Allen wrench is used in plumbing work for joining parts, in automobile work to tighten or loosening of parts, etc.

6] Impact wrench:

An impact wrench is an electric or pneumatic powered wrench that offers high torque for loosening or tightening fasteners with less effort and time.

The technology used in the impact wrench applies high torque to remove or tighten fasteners quickly.

The different sizes of sockets can use on the impact wrench to firmly hold the fasteners of different sizes as per the required application.

The impact wrench is usually seen in vehicle garage where it is used to remove or tighten log nuts during changing car wheels as well as it is also used in machines maintenance works, the automobile industry for assembling automobiles, etc.

7] Crowfoot wrench:

Crowfoot wrench is similar to an open-ended wrench but it doesn’t have a long handle. The crowfoot wrench has a square-shaped space below the jaws to attach the square drive of the socket wrench (Discussed below).

The crowfoot wrench can be used for loosening or tightening fasteners that are located at the difficult place where normal wrenches can’t use.

8] Lug wrench:

The lug wrench is a cross-shaped and circular cross-section wrench with different standard size sockets having hexagonal recess at each end.

As name suggests, this wrench is specially designed for the tightening or loosening of automobile wheel lug nuts.

The lug wrenches are also in the form of L-shaped having only two ends, which comes with hexagonal recess socket at the one end and a flat tip on another end.

9] Drum key:

The drum key is the ‘T’ shaped wrench which applications found in the maintenance of musical instruments.

In musical instruments like drums, this wrench is used to adjust tension rods as well as adjust the cymbal stand.

10] Dog bone wrench:

Dog bone wrench is the kind of socket wrench and as name suggests, it looks like a dog bone.

In this wrench, there are eight sockets, from which four joined sockets at the first end and the remaining fours are at another end. These all 8 sockets are of different sizes which is the advantage of this wrench means one dog bone wrench can do work of 8 different standard sizes wrenches.

Thus it is easy to carry and fast in operation and saves time from choosing particular size Socket or Box-ended wrenches from all sets.

The dog wrench applications are found in many works like in assembling or maintenance of vehicles.

11] Tap wrench:

The tap wrench is the wrench that is used to hold the threaded tool/tap and helps for producing internal threads inside the present hole on the workpiece surface.

There are two kinds of tap wrench which are ‘T’ shaped wrench (as shown in the above figure use collet to hold tool/tap) and double-end adjustable tap wrench (use clamps to hold tool/tap and produce external thread on workpiece).

12] Strap wrench:

A strap wrench is a tool that is rarely used during work. It uses the rubber strap to tighten or loosen elements. The strap wrench uses the rubber strap which holds the element and using the handle element is tightened or loosened.

The strap wrench applications are found in plumbing and household work.

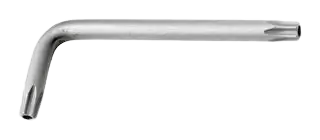

13] Torx key wrench:

Torx key wrench is the ‘L’ shaped wrench that is used on the fastener’s which have star shape recess on head.

The Torx key wrench is also recognized as the Star key. The ends of this wrench are of star shapes cross-section while the remaining body is of circular cross-section.

The Torx key wrench comes in different sizes having different torque handling capacities.

14] Ratching wrench:

A ratcheting wrench is a wrench that has a ratcheting head at one side and an open-end at another side.

The advantage of using a ratcheting wrench is that because of the ratcheting mechanism, it works in only one direction. Hence no needs to, again and again remove the wrench and then reset. Thus it is faster in operation.

Some ratcheting wrenches also comes with a swivel head which makes them able to use a wrench at any angle.

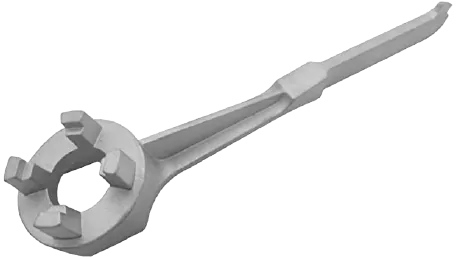

15] Bung wrench:

Bung wrench is a simple to use wrench that has 4 lugs at the head which helps to tighten or loosen the plugs.

Most bung wrenches are made from cast aluminum. The bung wrenches are lightweight hence there are easy to carry. The bung wrenches are used in many kinds of applications such as removing the steel or plastic cap and plugs of the drums.

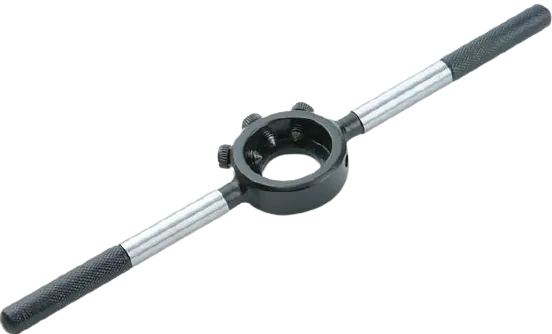

16] Die stockholder wrench:

Die stock-holder is the wrench used for holding the standard size dies and rotating with dies to cut external threading on the workpiece. The die stock-holder is made from cast iron while handles are made from mild steel.

The applications of the die stock holder wrench are found in producing threads onto the metal shafts.

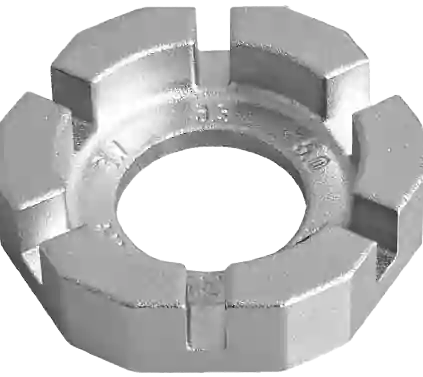

17] Spoke wrench:

The spoke wrench is a small hand tool that is used to tighten or loosen the bike spokes. The spoke wrenches come in many kinds as per sizes (in millimeters).

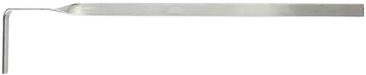

18] Tension wrench:

The tension wrench is a metal strip of flat shape that comes in both short and long sizes. The tension wrench comes in an ‘L’ shape in which the log flat end is used as a handle to rotate it.

The tension wrench is used for the lock picking.

19] Bionic wrench:

A Bionic wrench is a kind of adjustable wrench used to tighten or loosen fasteners. The bionic wrench head consists of six pins that firmly hold the fastner and apply equal forces on the fastener head along circumference.

The bionic wrench is made of steel and the grip is made up of plastic. The advantage of using the bionic wrench is that it can use for many sizes of fasteners.

This type of wrench is also helpful for loosening stuck bolts.

20] Oil filter wrench:

An oil filter wrench is a hand tool used to loosen or tighten a vehicle oil filter. This wrench uses a rubber strap that has an antiskid grip to hold the oil filter firmly without slipping.

The rubber strap oil filter comes in two different sizes. The handle of this wrench is made of plastic and the strap is made of reinforced rubber.

21] Socket wrench:

The socket wrench is a widely used and helpful wrench. This wrench consists of the ratcheting mechanism (located in the head) and square drive connected to the head.

There are different kinds and sizes of sockets that can be attached to the square drive of the socket wrench as per the required applications.

The ratcheting mechanism used in this type of wrench helps in working the wrench only in one direction. Therefore no need to, again and again remove and reset the wrench on the fastener.

22] Fan clutch wrench:

A fan clutch wrench is is flattened in shape. The fan clutch is used for the loosening or tightening of the fan clutch (engine cooling fan) in the vehicle.

Therefore fan clutch wrench applications are found in the automobile industry and auto garages.

23] Pedal wrench:

The pedal wrench is a wrench for the installation or removal of the bicycle pedal. The pedal wrench is made up of the flattened head and circular cross-section handle.

There are one or two ‘U’ shaped slots on the head which are help to tighten or remove the pedals on the cycle cranks.

Therefore pedal wrench applications are found in the bicycle manufacturing industries and in bicycle garages.

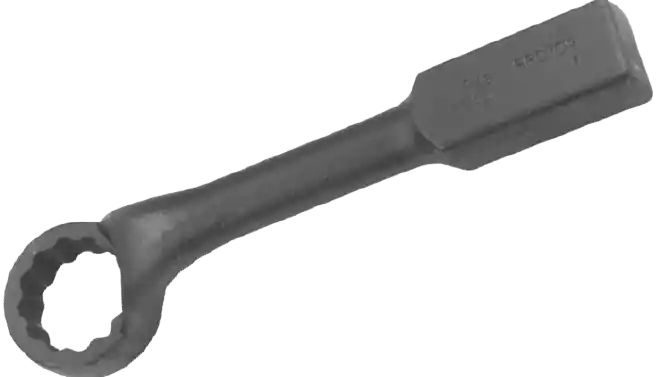

24] Hammer or Striking wrench:

The hammer wrench is the wrench that helps to provide extra effort to tight or loosen the stucked or tighten nut/bolt. One side of the hammer wrench has an open or close-end wrench and another side of the wrench has a large and heavy handle which is provided to apply force with a hammer.

Applying effort with hammer provides high torque on bolt/nut which helps in loosening or tightening of Nut/bolt.

Using a hammer wrench we can remove the stuck bolts.

25] Armorer’s wrench:

Armorer’s wrench is a multi-function tool used by armorers for many kinds of weapons repair or maintenance works. The armorer’s tool is thick and flat shape which is made from stainless steel.

It has many wrenches features such and it is used for Barrel nut, Flash hider, Cocket, Butterstock tube, Castle nut, Compensator and Muzzle devices, etc.

Adjustable wrenches:

1] Crescent Wrench:

An Crescent Wrench is the widely used kind of wrench, which is useful for loosening or tightening operation in almost all works.

As its name suggests, this wrench jaws can be adjusted for a variety of required applications. It consists of the worm screw and two jaws from which one jaw is fixed and the other is adjustable means the adjustable jaw can move horizontally as per the movement of the worm screw.

Thus when we turn the worm screw by thumb, the adjustable jaw moves horizontally, So as per the head size of the fastener, we can set an Crescent Wrench for their tightening or loosening.

So, it is a better choice to have an Crescent Wrench rather than choosing a particular standard-size wrench from a big set of wrenches. It is very commonly used in plumbing as well as garages.

2] Pipe wrench:

The pipe wrench is a kind of adjustable wrench that is used for the tightening of loosening circular pipes which are connected by threaded joints.

The pipe wrench is made up of two steel jaws having serrated teeth on them to hold the pipe firmly. From two jaws, the lower one is fixed to the body while the upper one is adjustable (Can move in an up and down direction).

The upper adjustable jaw (having external teeth at the end) can adjust with the help of the Adjustment Nut (having internal teeth).

Because of the ability of serrated teeth to inserts on the pipe surface to hold firmly, a pipe wrench is also used to loosen the stuck bolts which are difficult to remove by the open or close-ended wrenches.

Read here: Difference between Pipe wrench and Monkey wrench

3] Basin wrench:

The basin wrench is the hand tool that is used in home plumbing work. A Basin wrench is consists of a spring-loaded jaw at one end and a handle at the another end of the body.

The basin wrench is used for the loosening or tightening of kitchen or home pipeline fasteners that are located in narrow spaces where other wrenches can’t use.

4] Plier wrench:

The plier is a commonly used wrench that has the capacity to operate on wide sizes fasteners. As per the sizes of the fastener, the jaws of the plier wrench can be adjusted with the push button.

The plier wrench has double teeth engagement to adjust the jaws. The plier wrench is used in plumbing applications, fitting square as well as hexagonal head fasteners, etc.

5] Alligator wrench:

An alligator wrench is a wrench with two jaws at both side from which one side has one serrated jaw and a flat jaw while the other side has one fixed jaw and adjustable jaw.

This wrench is recognized as an alligator wrench since its head looks like an alligator head. The alligator wrench has self-ratcheting action because of threaded and flat jaws. Hence there is no need to, again and again remove and install it.

Along with a hexagonal head fastener, this wrench can also be used for a square head fastener.

6] Monkey wrench:

Monkey wrench is a rarely used wrench which was largely used at the time of 19th as well as some time in 20th century.

This wrench is now replaced by the kinds of adjustable wrenches which are light-weight and easy to use rather than bulky and thick monkey wrench.

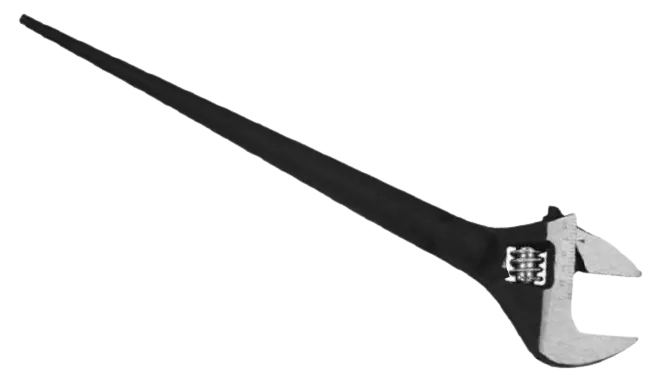

7] Spud wrench:

A spud wrench is a hand tool that has an adjustable wrench (as shown in above figure) or close-end wrench at one side and the other side has a tapered spike. The Spike side of this wrench is used to align the holes of parts at the time of fitting.

The spud wrench application is found in the ironworker’s job during construction where they use it for aligning girder and beam holes for joining them.

FAQs:

-

What are the Wrenches that are mostly used?

The most common wrenches people widely use are Crescent Wrenches, Socket wrenches, Pipe wrenches, Plier wrenches, and Combination wrenches.

-

What things should I consider before choosing Wrench?

There are a lot of commonly used and special-purpose wrenches available in the market which comes in different standard sizes.

So, first of all, you have to know which is suitable for your work and then choose the perfect size wrench that will be fitted properly.

Last words:

So, friends These are all the different types of wrenches which are used in work from which some are commonly used while some are for the special application. That’s all for this article. I hope you have totally learned about the different kinds of wrenches.

And, before reading this article, if you were in trouble for finding the required wrench, then I think you may have decided the perfect one for you.

If are you looking for some wrench that is not included in the article as well as if you want to know detail about any of the wrench mentioned above, then don’t be hesitate to comment on this article, we will answer them in this article.

Media credits:

- Crowfoot wrench image by Amazon

- Lug wrench image by grainger

- Drum key image by Amazon

- Dog bone wrench image by Joom

- Tap wrench image by User:Omegatron, CC BY-SA 3.0, via Wikimedia Commons (Modified)

- Strap wrench image by Amazon

- Basin wrench image by Oxtools

- Torx key wrench by element14

- Ratcheting wrench image by lowes

- Bung wrench image by Amazon

- Tension wrench image by Lockpicking center

- Oil fillter wrench image by Amazon

- Monkey wrench image by ebay

- Armorer’s wrench image by Gero Gun

Thanks for taking the time to write this I just bookmarked this site so I can stay updated.

I love plumbing thanks for the posts