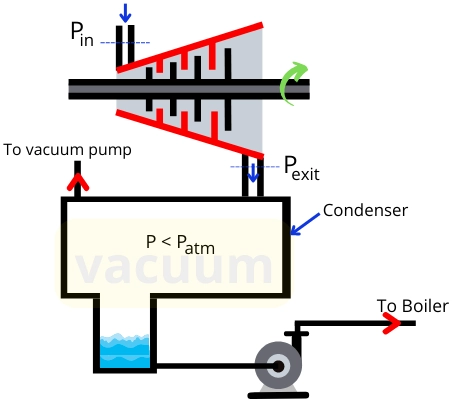

Vacuum is required at the end of the turbine to lower the pressure at the exit of the turbine. Thus the steam can be expanded more into the turbine and the maximum energy of the steam can be extracted to increase the power output.

Contents:

Why vacuum is required in steam turbine?

The steam turbine expands the steam from the boiler pressure (`P_{\text{in}}`) to the condenser pressure (`P_{\text{exit}}`) to raise the kinetic energy of steam which is utilized to rotate the turbine blades.

| `\DeltaP` = `P_{\text{in}}` – `P_{\text{exit}}` |

The term `\Delta P` indicates the total pressure drop inside the turbine and as the pressure drop (`\Delta P`) in a turbine increases, the kinetic energy supplied to the turbine also increases. And thus the power developed by the turbine also increases.

As per the above formula, the total pressure drop (`\Delta P`) in the turbine can be increased by lowering the pressure at the exit (`P_{\text{exit}}`) of the turbine which results in an increase in power developed by the turbine.

Hence the vacuum created in the condenser helps to lower the pressure (below the atmospheric pressure) at the exit (`P_{\text{exit}}`) of the turbine. Thus it helps to extract the maximum extent of energy from the steam.

Therefore the vacuum is useful to increase the power output in the turbine. Also, due to the increase in turbine power output, the specific steam consumption for the turbine gets decreases and the efficiency of the turbine gets increases.

How vacuum is created in condenser?

Developing the vacuum inside the condenser reduces the pressure at the turbine exits and increases the power output.

The vacuum in the condenser is developed by using the following methods:-

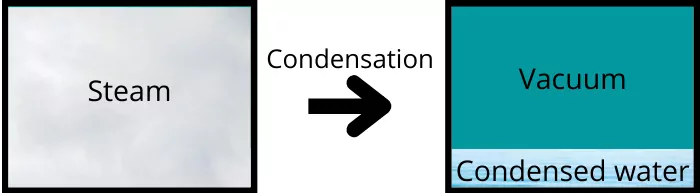

1] By condensation process:-

The condensation of steam creates a vacuum inside the condenser. During the condensation process, the water vapors lose their latent heat to the cooling medium and change their phase from vapor to liquid.

During this phase change, the volume of the steam is reduced by a large extent. Thus it creates free space or vacuum inside the condenser.

2] By use of vacuum pumps:-

The vacuum generation due to condensation does not start just after the start of the turbine. Therefore to develop the vacuum during the starting of the turbine, the vacuum pump is connected to the condenser.

The vacuum pump attached to the condenser also helps to remove the air and non-condensing gases from the shell of the condenser since the presence of air and non-condensing gases can affect the heat transfer process in the condenser and lowers the vacuum inside the condenser.

Effect of high vacuum in steam turbine:

The effects of a higher vacuum on the steam turbine are discussed below:-

1] Increased steam consumption:-

The higher vacuum inside the condenser draws more steam to the condenser. Therefore it increases the specific steam consumption of the turbine.

2] Increases the moisture content (Lowers the dryness fraction):-

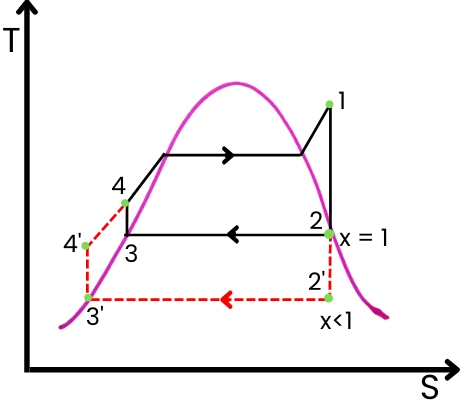

The above figure shows the Rankine cycle used for the steam power plant.

Process 1-2 in the above figure shows the steam expansion in the turbine with a normal vacuum and process 1-2′ shows the steam expansion with a higher extent of the vacuum.

During the expansion with a normal vacuum, the steam leaves the turbine with very less moisture content (high dryness fraction). Thus it never harms the turbine components.

As shown in the above figure, with the high amount of vacuum, the steam gets expanded up to a higher extent and enters in the saturation region. Thus it leads to an increase in the moisture content in the steam.

This moisture present in the high-velocity steam can damage the low-pressure section of the turbine.

Effect of low vacuum in steam turbine:

In the steam turbine, the lowering of the vacuum causes due to some of the following reasons: Failure in the condenser cooling system, Due to the presence of non-condensing gases, Because of the failure of the vacuum pump.

The low vacuum at the end of the turbines affects the turbine performance as given below:-

1] Decreased power output:

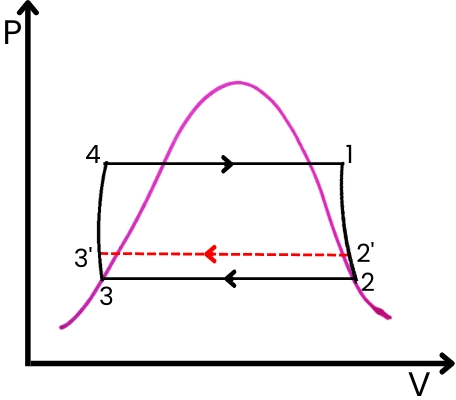

The lower vacuum inside the condenser increases the pressure at the exit of the turbine. This condition is also known as Back pressure in the steam turbine.

Thus it will lower the total pressure drop across the turbine and hence the steam will not get expanded up to the maximum extent. Resulting the turbine will not extract maximum energy from the steam. Therefore it will result in a lowering of turbine power output.

In the above figure, cycle 1-2-3-4-1 shows the Rankine cycle with a normal vacuum, and cycle 1-2′-3′-4-1 shows the Rankine cycle with a low vacuum.

As shown in the above figure due to the lowering of the vacuum, the area enclosed by the Rankine cycle decreases thus the net work done by the Rankine cycle also decreases.

2] Increases specific steam consumption:

Due to the lowering of vacuum, the work output from the turbine gets decreases thus the turbine needs more steam for the same amount of power generation. Hence it increases the specific steam consumption of the turbine.