What is the Volumetric efficiency of IC engine?

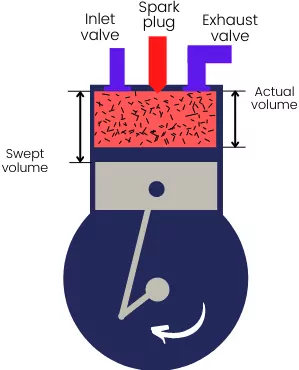

The volumetric efficiency is the ratio of the actual volume of air or air-fuel mixture sucked by the piston during the suction stroke to the swept volume of the engine.

OR

Volumetric efficiency is the ratio of the actual mass of charge drawn by the piston to the theoretical mass of charge drawn during suction stroke.

The formula of the volumetric efficiency is,

`\eta _{V} =\frac{\text{Actual volume}}{\text{Swept volume}}`

`\eta _{V} =\frac{V_{a}}{V_{S}}`

It can be also written as,

`\eta _{V} =\frac{V_{a}}{\frac{\pi}{4}D^{2}L }`

Where,

D = Bore diameter

L = Length of piston stroke

The value of this ratio is always less than 1 in the case of naturally aspirated engines.

The engine which has low volumetric efficiency results in improper combustion in the engine, since the low volumetric efficiency means the engine sucked less amount of air or air-fuel mixture.

In the naturally aspirated four-stroke engines, the volumetric efficiency varies between 85 to 90 % while in the naturally aspirated two-stroke engines, it varies between 70 to 80 %.

If engines have turbocharging or supercharging then volumetric efficiency is 100 % or more than that since in these systems turbochargers or superchargers devices forces the compressed air to the engines.

Therefore, the volumetric efficiency is very important since as engine volumetric efficiency increases, the engine power or torque output increases while if volumetric efficiency decreases, the engine power or torque output also decreases.

Why engines have low valumetric efficiency than 100%?

The naturally aspirated engines have low thermal efficiency due to the following reasons:-

1] When the piston moves from BDC to TDC to release the exhaust gases through the exhaust valve, at that time piston comes at TDC and the exhaust valve closes but still some amount of burnt gases remains at the clearance volume which pressure is more than atmospheric pressure.

So, after the exhaust stroke when the Inlet valve is open and the piston moves from TDC to BDC to suck the fresh charge, this fresh charge not enters in the chamber until the vacuum is created in the chamber since the vacuum is not created due to the presence of remaining pressurized burnt gases.

Hence after some piston movement from TDC to BDC, the vacuum forms and the charge enters into the chamber. But due to this delay, the actual volume of charge is less than the swept volume.

2] At the high speed of the engine, the piston moves fast inside the chamber due to which during the suction stroke the piston fastly moves from TDC to BDC, and the inlet valve closes. Therefore, only less amount of charge enters into the chamber.

Methods to improve the volumetric efficiency of IC engine

The following are the ways using which we can improve the volumetric efficiency of Internal combustion engine:

- Increasing the size of the intake valve which causes the more amount of air or air-fuel mixture will enters into the engine.

- Using the forced induction systems like supercharging, turbocharging which forces the compressed air or mixture inside the engine using the compressor as well as this systems increases the density of mixture which helps in entering more air or air-fuel mixture into the engine.

- Using the intercooler before the charge enters into the cylinder since intercooler increases the density of the charge which helps in entering more amount of charge in engine.

Read also: