There are numerous different criteria to classify IC engines. Depending on how many strokes they accomplish in a single combustion cycle they are classified as two-stroke and four-stroke engines.

In this article, we will go over two-stroke engines in detail, which will help to clear up any confusion regarding this topic.

In this article, we’re going to discuss:

- What is 2 stroke engine?

- Construction of 2-stroke engine:

- How does a 2 stroke engine work?

- Types of 2 stroke engine:

- 2 stroke engine port timing diagram:

- Advantages of two stroke engine:

- Disadvantages:

- Applications of 2 stroke engine:

- FAQs:

What is 2 stroke engine?

Two-stroke engines are IC engines in which a single combustion cycle completes within two strokes of the piston (One upward and one downward stroke) or within one complete revolution of the crankshaft.

The first 2 stroke engine was developed by the German inventor Karl Benz in 1879.

This IC engine produces power stroke during each revolution of the crankshaft (during each downward stroke); thus, it provides a higher power to weight ratio than a four-stroke engine.

The construction of these engines is less complex than 4 stroke engines as they use piston-controlled ports instead of valves.

In a two-stroke engine, the crankcase also takes part in an engine cycle. The fresh charge from the carburetor first enters the crankcase and then it is transferred to the combustion chamber.

This engine uses the ‘total loss lubrication’ method to lubricate the engine components in which the oil is previously added to the fuel. Thus, the oil directly enters the engine along with the fuel.

Construction of 2-stroke engine:

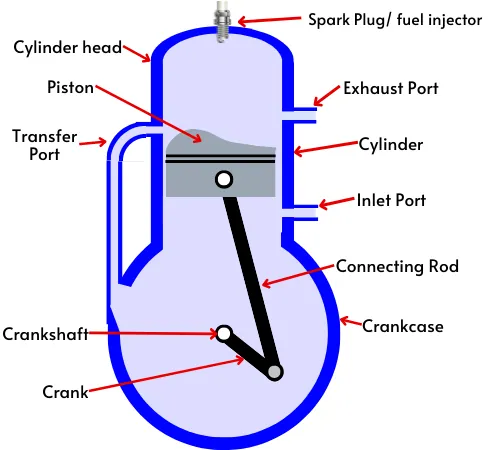

The two-stroke engine generally consists of the following parts:

1] Cylinder: Basically, an engine cylinder guides the movement of the piston and it also helps to form the combustion chamber along with the cylinder head and piston.

Other than these primary functions, the cylinder in two stroke engines also helps to exchange the gases in the combustion chamber.

It means that this cylinder has ports (inlet port, exhaust port, transfer port) to enter the fresh charge, expel the exhaust, and to transfer the fresh charge respectively.

2] Piston: The piston helps to convert the thermal energy of combustion products into mechanical work. In addition to this, in the two-stroke engine, the piston helps to cover and uncover the opening of ports.

Because there is no oil reservoir in the crankcase, the piston never has an oil control ring while it only has compression rings.

3] Crankcase: A crankcase is an enclosure made over the crankshaft that supports the crankshaft and protects it from dirt and shocks.

In a two-stroke engine, the crankcase performs a vital role to suck and transfer the fresh charge. For this purpose, an inlet port and transfer ports are connected to the crankcase.

A fresh charge/air enters the crankcase through the inlet port and then it is transferred to the combustion chamber through the transfer port.

The upward stroke of the piston creates a partial vacuum inside the crankcase to suck the fresh charge and the downward stroke forces the charge to move into the transfer port.

4] Cylinder head: Because of the absence of valves and camshaft, the cylinder head of a two stroke engine has a simple construction.

It forms the upper portion of the combustion chamber, as well as it also has provision to fit the spark plug or the fuel injector.

5] Connecting rod: The connecting rod along with the crankshaft helps to convert the reciprocating motion of the piston into the rotary motion of the crankshaft.

The small end of the connecting rod is connected to the piston with the help of a gudgeon pin and the big end is connected to the crankshaft.

6] Ports/Valves: The two-stroke engine has the following ports/valves.

(a) Inlet port/valve: The two stroke engine has a piston-controlled intake port or intake valve to suck the fresh charge into the crankcase.

The intake port is present on the cylinder wall at the lower side of the piston and its opening is controlled by the piston. If the engine is using an intake valve, then it is present on the surface of the crankcase.

(b) Exhaust port/valve: The exhaust port is the opening made on the cylinder surface that is connected to the exhaust manifold. The exhaust port is present above the transfer port, thus during downward stroke, it opens before the opening of the transfer port, and during upward stroke, it closes after the closing of the transfer port.

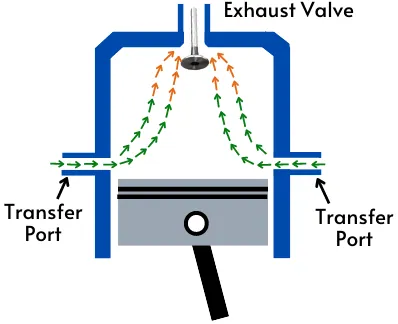

In the case of a uniflow scavenging system, the 2-stroke engine has an exhaust valve (instead of the exhaust port) which is fitted at the top of the cylinder head.

(c) Transfer port- The transfer port helps to transfer the fresh charge from the crankcase to the engine cylinder.

7] Spark Plug/ Fuel injector: A spark plug is necessary in two-stroke SI engines to ignite the air-fuel mixture while the fuel injector is necessary in the case of the two-stroke CI engines for injecting fuel into the compressed air.

How does a 2 stroke engine work?

The whole cycle of the 2 stroke engine completes within two strokes of the piston. i.e. upward stroke and downward stroke.

In this engine, the crankcase also takes part in an engine cycle, and it helps to suck and compress the fresh charge required for the next consecutive combustion cycle happening in the combustion chamber.

Due to these simultaneous processes happening in the crankcase and combustion chamber, it may be difficult to understand the working on the basis of the strokes.

Thus for easy understanding let’s see the working of the two-stroke engine based on ‘How working fluid for single combustion cycle travels in the engine’.

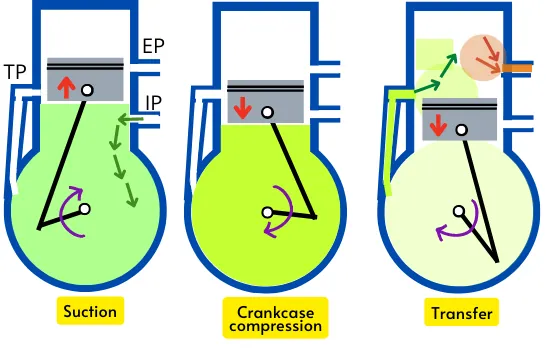

1] Suction:

It is carried out in the crankcase during the upward stroke of the piston. Due to the upward movement of the piston, a partial vacuum is created in the crankcase and as the piston uncovers the inlet port, the fresh charge/air enters the crankcase.

2] Crankcase compression and transfer:

During the downward stroke, as the intake port becomes closed, the charge in the crankcase starts to get compressed by the downward movement of the piston. But it only starts after the piston covers the transfer port and inlet port and ends when the piston uncovers the transfer port.

As the transfer port becomes open, the charge inside the crankcase is pushed into the cylinder through the transfer port because of the downward movement of the piston.

3] Compression:

During the upward stroke, when the piston covers the transfer port and exhaust port, the charge into the cylinder gets compressed by the piston.

4] Combustion and expansion:

When the piston reaches TDC, the spark plug/ fuel injector helps to ignite the mixture to start the combustion. The pressure developed by the combustion products pushes the piston in a downward direction.

5] Exhaust (and transfer):

The process of expansion ends when the piston uncovers the exhaust port during the downward stroke and the exhaust gases start to flow outside through the exhaust port.

Just after the opening of the exhaust port, the piston also uncovers the transfer port which helps for the better scavenging of the engine cylinder.

Here the one cycle of the two-stroke engine completes. In this manner, the two-stroke engine repeats the same sequence of processes to continuously generate mechanical work.

Types of 2 stroke engine:

Based on the different criteria, the 2 stroke engine can be classified as follows:

A] Based on the type of fuel used:

1) Two-stroke petrol engine:

These are SI engines that run on gasoline and it has a spark plug at the cylinder head.

2) Two-stroke diesel engine:

These are CI engines that use diesel as fuel and it has a fuel injector at the top of the cylinder head for fuel injection.

B] Based on the type of intake:

1) Piston controlled intake:

In this case, an intake port is provided on the lower side of the cylinder surface. Similar to the other ports, its opening is also controlled by the reciprocating piston.

2) Reed valve:

It is a unidirectional (One-way) valve fitted on the crankcase. It gets opened during the upward stroke of the piston and remains closed during the downward stroke.

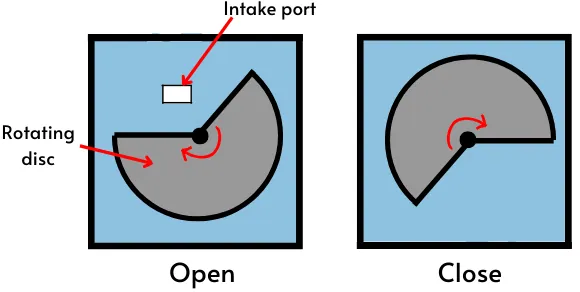

3) Rotary valve:

The rotary valve has a rotating component that covers and uncovers the opening in a crankcase.

The rotating component may be a disc or drum which gets power from the crankshaft.

C] Based on the method of scavenging:

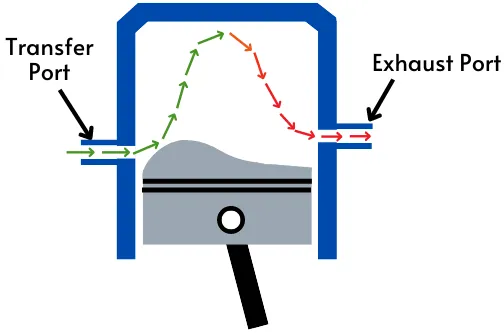

1) Cross-flow:

In cross-flow scavenging, the transfer port and exhaust port are constructed opposite to each other.

Due to the shape of the piston head, the fresh charge coming from the transfer port is directed toward the cylinder head which helps to effectively push the exhaust gases in a downward direction toward the exhaust port.

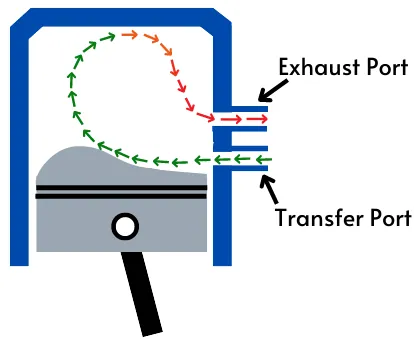

2) Loop scavenging:

In such engines, the transfer port is provided below the exhaust port on the same side. In this method, the fresh charge moves in a loop form.

3) Uniflow scavenging:

The engine with the uniflow scavenging method has an exhaust valve (instead of an exhaust port) at the cylinder head and it has two transfer ports on opposite surfaces of the cylinder.

Thus, in this case, the fresh charge and exhaust gases move in the same direction (upward direction).

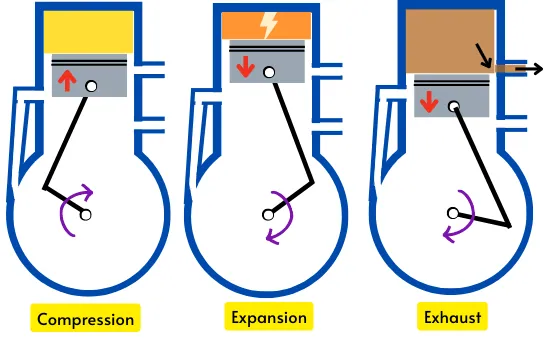

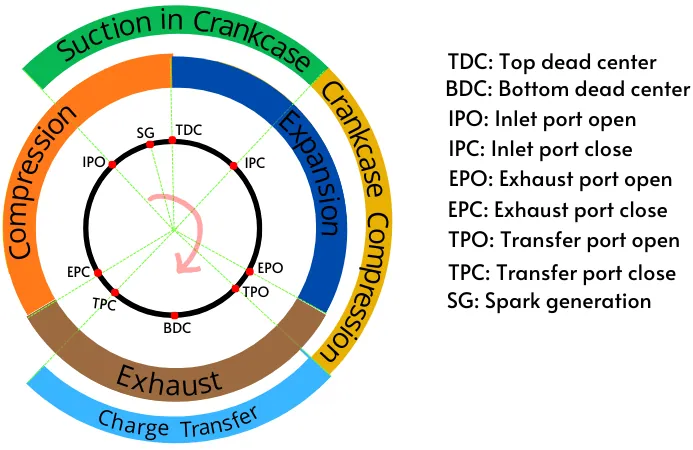

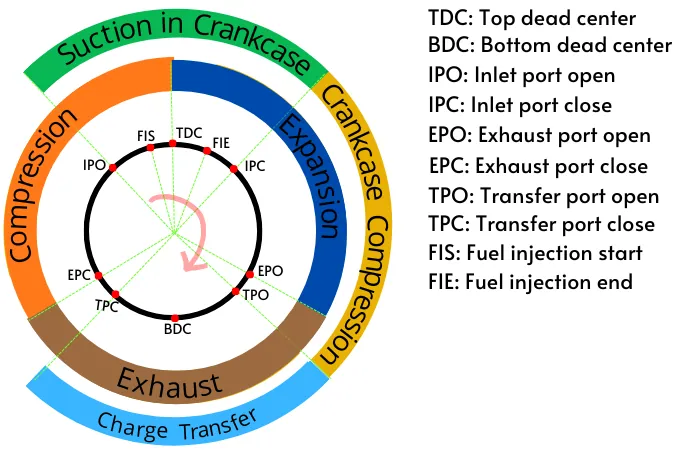

2 stroke engine port timing diagram:

The time of opening and closing of the ports with respect to the crank angle has a great impact on the performance of 2 stroke engine. The port timing diagram indicates the operating of the ports with respect to the crank angle.

Below fig. a shows the port timing diagram for the 2-stroke SI engine.

The above diagram provides an ease to understanding the sequences of the processes occurring during the combustion cycle.

The outermost arc shows the processes done in the crankcase and the middle circle indicates the processes happening in the cylinder or combustion chamber.

It shows that the exhaust port opens before BDC during the downward stroke and closes a few degrees after the BDC during the upward stroke. The transfer port opens a few degrees after the opening of the exhaust port and it closes a few degrees before the closing of the exhaust port.

The overlapping of the opening time of the exhaust port and transfer port helps to improve the scavenging effect.

The inlet port in the crankcase opens a few degrees before the TDC during an upward stroke and it closes a few degrees after TDC during the downward stroke.

The opening period of the inlet port indicates the suction in the crankcase and the period from the closing of the inlet port to the opening of the transfer port indicates the compression of the charge in the crankcase.

The SG in the above diagram indicates the generation of a spark to ignite the air-fuel mixture.

The below figure indicates a port timing diagram for 2 stroke CI engine. In this diagram, the FIS indicates the starting of the fuel injection and the FIE indicates the end of the fuel injection.

Advantages of two stroke engine:

Following are some of the advantages of a 2 stroke engine:

- High power output as it produces a power stroke during each crankshaft revolution.

- It provides quick acceleration because of a higher power.

- It has a higher power-to-weight ratio.

- Easy construction due to the absence of a complex valve actuating system.

- Maintainance is easier due to the absence of a lubricating system, and valve mechanism.

- Lighter in weight in comparison with 4- stroke for same power output.

- Lower maintenance cost.

- Lower setup cost.

- It uses a lighter flywheel as the distribution of turning moment is more uniform due to the fewer idle strokes.

- It occupies less floor area.

- The 2-stroke engine can work in any position (As the lubricant receiver is absent).

Disadvantages:

Following are some of the disadvantages or limitations of a two stroke engine:-

- It has less life in comparison with a 4-stroke engine.

- Higher wear rate due to the lack of a dedicated lubricating system.

- It uses more lubricating oil as the oil is mixed with the fuel.

- Poor scavenging as fresh charge also gets lost through the exhaust port.

- Less fuel efficiency and overall efficiency.

- The operation is noisier and creates more vibrations.

- Higher fuel consumption.

- The exhaust contains a higher extent of pollutants due to improper combustion.

Applications of 2 stroke engine:

Because of the requirement for a higher power-to-weight ratio, the two stroke engine is used in the following applications:-

- Chain saw

- Leaf blowers

- Dirt bikes

- Beach ATVs

- Jet skies

- Small AC generators

- Water pump

- Mopeds

- Minibikes

FAQs:

-

What does two strokes mean in the two-stroke engine?

The term ‘two strokes’ in a 2 stroke engine indicates that the one combustion cycle of this engine completes within two strokes of the engine.

-

Which one is the more effective 2- or 4-stroke engine?

The 4 stroke engines are more efficient than the two stroke engines.

-

Are valves used in two-stroke engines?

Most two stroke engine uses ports (intake port, exhaust port, and transfer port) while some engines use valve for the exhaust and crankcase intake.

-

Does a two-stroke engines require oil?

In two stroke engine the oil is added to the fuel to lubricate the engine components.

-

What are the uses of two stroke engines?

The two stroke engines are used in applications where a more power-to-weight ratio is necessary. Thus the 2 stroke engines are used in applications like chain saws, dirt bikes, AC generators, etc.

-

Why are 2-stroke engines so rarely used?

The two stroke engines have poor scavenging which causes the unburnt charge or incompletely combusted charge to escape through the exhaust. Thus the exhaust of 2 stroke engine contains more pollutants. Hence the use of a two stroke engine is rare in comparison with 4 stroke engines.

-

Why 2-stroke engines are considered more powerful than 4-stroke engines?

The two-stroke engine produces a single power stroke during each crankshaft revolution while the 4 stroke engine produces a single power stroke for every two revolutions of the crankshaft. Thus the 2-stroke engines produce more power in comparison with 4-stroke engines.

You may like this: