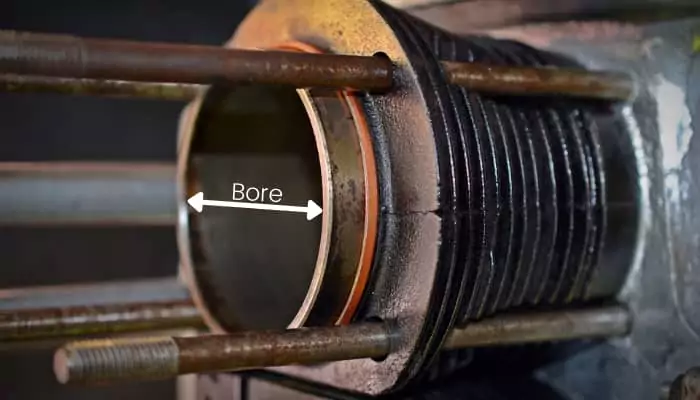

What is Bore in IC engine?

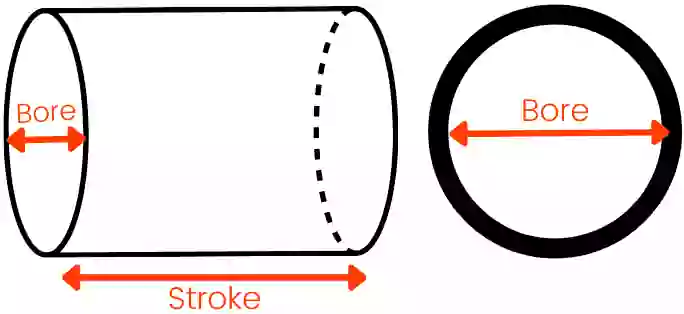

The Bore in the IC engine is defined as the internal diameter of the engine cylinder. It is one of the important term related to the IC engine.

As per the Bore and stroke of the engine, there are three different types of engine that are oversquare, square, and undersquare. Using the Bore and stroke, we can calculate the volume displaced by the piston inside the engine’s cylinder.

The formula of the engine bore is,

Bore =`\sqrt{\frac{ED\ (\text{CC})}{\frac{\pi }{4}\times L\times N}}`

Where,

ED (CC) = Engine displacement in Cubic centimeter

L = Stroke length in centimeter

N = Number of cylinders

In this article, we’re going to discuss:

- Bore vs stroke:

- Big bore or long stroke which is better?

- Why engine bore is measured?

- How is engine bore measured?

Bore vs stroke:

| Bore | Stroke |

|---|---|

| It is the internal diameter of the engine cylinder. | It is the distance travel by piston from TDC to BDC. |

| Big bore than stroke increases the engine power output. | A longer stroke than a bore increases the efficiency of the engine. |

Big bore or long stroke which is better?

The Big bore helps in increasing the horsepower of the engine as compared to the Long-stroke while if high engine efficiency is required then the Long stroke is considered.

The engine which has a big bore than stroke resulting in the crankshaft rotating at a higher speed. Hence due to an increase in engine speed, high horsepower is obtained at the output.

The engine which has Long-stroke than bore resulting the less surface area to dissipate heat from the engine and uses this heat to push the piston that makes the engine more efficient.

Hence both have their advantages and disadvantages.

Why engine bore is measured?

The engine bore is measured during the engine assembling because the changes in cylinder dimensions over time can cause a decrease in power output as well as an increase in fuel consumption.

The engine bore is measured to check for Taper, Out of round, and oversize of the bore.

- Taper: Due to the wear inside the cylinder over time, the different bore is obtained at the top and bottom of the cylinder as shape like Taper.

- Out of round: Newly installed cylinder is round shape but after the time it becomes the oval shape.

- Oversize/Undersize: The cylinder becomes oversized or undersized.

The most common gauges used for the engine bore measurements are the Bore dial gauge and Micrometer gauge.

How is engine bore measured?

The engine bore is measured as per the following steps:-

- Check the bore (Consider 15mm) as per the engine specifications manual.

- Set the 15mm size extension rod to the Bore dial gauge.

- Set the 15mm in the micrometer and Hold the Bore dial gauge head between the anvil and spindle of the micrometer.

- Adjust zero in the bore dial gauge for the maximum reading.

- Place the head of Bore dial gauge inside the cylinder and check the deviations of gauge pointer from zero. If the pointer stops at after the zero (Clockwise), it indicates the bore is over than 15 mm while If the pointer stops at before the zero (Clockwise), it indicates the bore is under the 15mm.

- Place the gauge at different locations and note down the reading.

After the bore measurement, if the cylinder is not as per the standard size then it is rebored at the workshops and the suitable size piston is used with that.