A centrifugal clutch is a type of clutch that operates using centrifugal force, requiring no manual operation.

It is commonly used in vehicles with continuously variable transmissions, it engages and disengages automatically based on engine speed, providing simple construction and low maintenance.

In this article, we’re going to discuss:

- What is a Centrifugal clutch?

- Construction:

- Working of Centrifugal clutch:

3.1. Engagement:

3.2. Disengagement: - Advantages of Centrifugal clutch:

- Disadvantages of Centrifugal clutch:

- Application of Centrifugal clutch:

What is a Centrifugal clutch?

Centrifugal Clutch is one of the friction type clutch. This type of clutch works on the Centrifugal Force. No manual operation is required to operate a clutch.

It is used in fixed (preset) speed applications and in vehicles with continuously variable transmission (CVT) system. No Gearbox is used in such types of vehicles.

Construction:

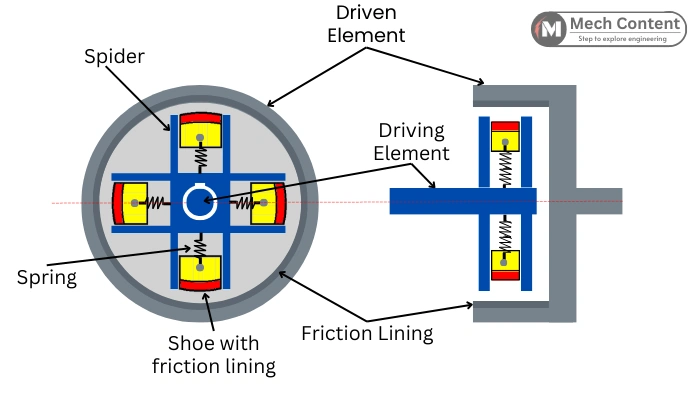

It consists of a Driving element, a Driven element, Spider, Shoes, & Spring.

The spider is located on the driving element. In the spider, Shoes (which have a friction lining on their outer surface) are connected to the driving element with the help of spring as shown in the above figure. These shoes expand radially in the way provided by a spider.

The spring can be adjusted for the expansion limit to set the vehicle speed limit.

The driving element is connected to the engine crankshaft & driven element is connected to the transmission system.

The driven element has a friction lining at the inner surface.

Working of Centrifugal clutch:

Engagement:

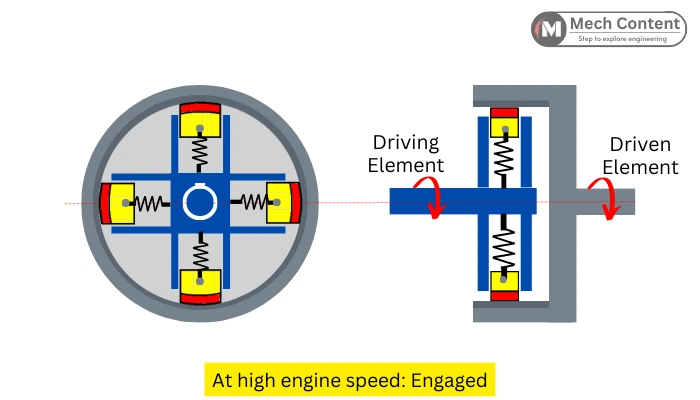

When the vehicle engine starts, the driving element starts rotating with a crankshaft.

When the driving element starts rotating, the shoes expand radially due to centrifugal force.

When the driving element achieved preset speed, the friction starts between the shoes & driven element. Hence due to friction, the driven element starts to rotate at the speed of the driving element. So such a way clutch gets Engaged.

Disengagement:

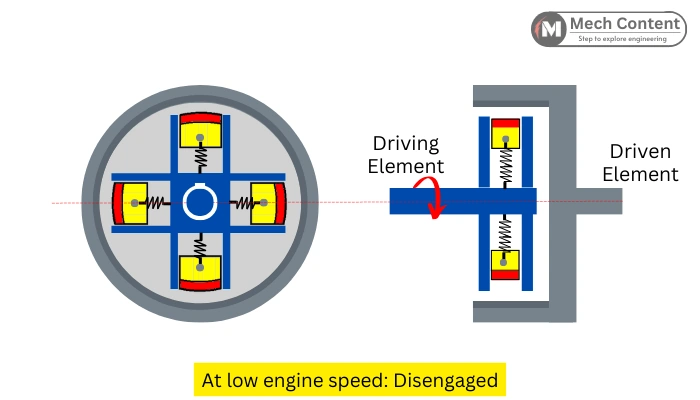

When the vehicle engine stops, the driving element stops rotating. Hence shoes come inwards the spider. Hence in such a way clutch gets Disengaged.

Advantages of Centrifugal clutch:

The advantages are as follows:

- Simple in construction.

- Less maintenance is required due to simple construction.

Disadvantages of Centrifugal clutch:

The disadvantages are as follows:

- Slip occurs between shoes & driven element.

- Low power transmission capacity due to slip occurs.

Application of Centrifugal clutch:

This kind of clutch is used in the following vehicles:

- Mopeds

- Scooters.

Read also: