What is a Cone clutch?

A Cone clutch is a type of friction clutch in which the two conical shape components are used for engagement and disengagement.

As compared to plate type clutch, In this type, the clutch flywheel changes to an outer cone and the pressure plate changes to an inner cone.

In this article, we’re going to discuss:

- Working principle:

- Construction:

- Cone clutch working:

- Cone clutch advantages:

- Cone clutch disadvantages:

- Application of cone clutch:

Working principle:

Cone clutch works on the Principle of friction.

The outer cone has a friction lining on its inner conical surface & Inner cone has friction lining on its outer conical surface.

Friction between these two cones is cause for the power transmission from the flywheel to the gearbox.

Construction:

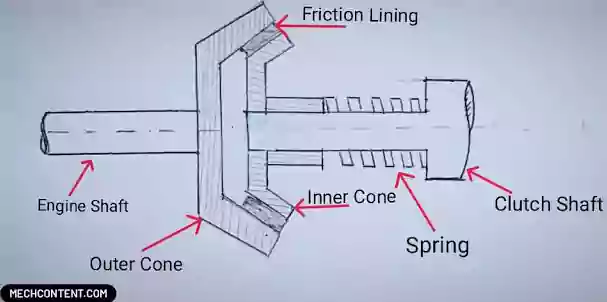

It consists of an Inner cone, Outer Cone, and Spring.

The outer cone has a friction lining on its inner conical surface & inner cone has a friction lining on its outer conical surface.

The Outer cone is connected to the input engine shaft & inner cone is connected to a clutch shaft. The Inner cone is operated by the clutch pedal through a linkage arrangement.

Cone clutch working:

The working of the cone clutch in the engagement and disengagement for power transmission from the engine to the gearbox is as follows:-

Engagement:-

In the normal position of clutch, When a vehicle is running, The inner cone is pressed inside the outer cone. Therefore due to the friction occurs between them, Power is transmitted from the input shaft to the clutch shaft, Hence the clutch is in Engage position.

Disengagement:-

When the driver presses the clutch pedal, The inner cone moves towards the right side against compressing spring (which means the inner cone comes outside from the outer cone), Hence there is no friction between the outer cone & the inner cone. Therefore no power transmission takes place from the engine to the gearbox. Hence in such a way, Clutch Disengages.

When the Driver releases the clutch pedal, The inner cone again returns towards the left side due to the expansion of the compressed spring. Hence Clutch is again Engages.

Cone clutch advantages:

The advantages are as follows:

- It has the advantage of higher power transmission capacity as compared to other plate types clutches since more surface area.

- Simple in construction.

Cone clutch disadvantages:

Cone clutch has the disadvantage that if cones have less cone angle then there becomes a difficulty in disengagement.

Application of cone clutch:

Currently, cone clutch is used in the following applications:-

- It is used in speed boats.

- It is used as a synchronizer in the synchromesh gearbox for clutch engagement.

- It is used in racing car’s transmission systems.

Read also: