What is constant mesh gearbox?

Constant mesh gearbox is one type of manual transmission gearbox in which lay shaft gears constantly mesh with output shaft gears. Hence there is no sliding of the gears for meshing as in a sliding mesh gearbox.

In this gearbox, helical and double helical gears are used for the power transmission.

All the gears on the output shafts are mounted on the output shaft using bearings. Thus output gears freely rotate on the output shaft without affecting the speed of the output shaft.

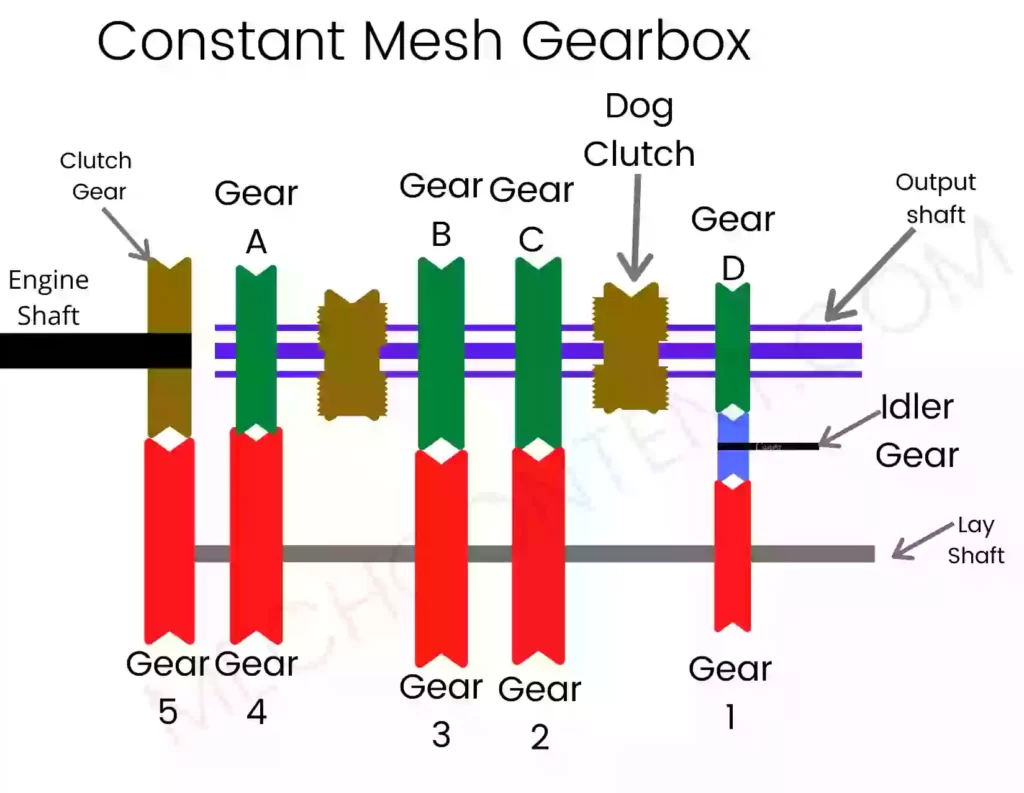

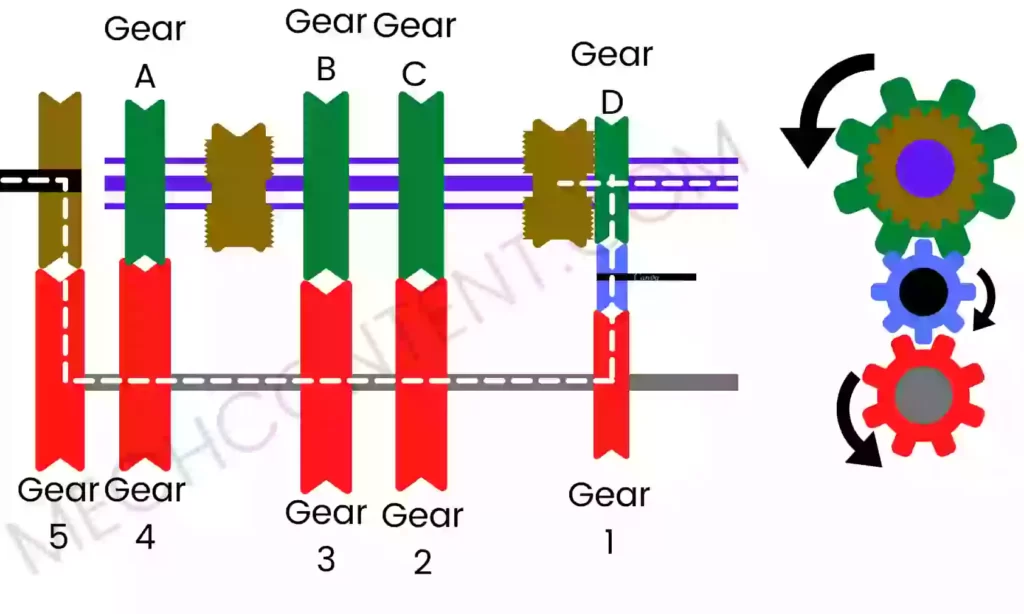

The below figure indicates the basic structure of a constant mesh gearbox.

The dog clutch is used in this gearbox, As per the action of the gear pedal, this dog clutch slides on the main shaft and meshes with the desired output shaft gears.

The dog clutch rotates with the output shaft. When the dog clutch engages with any gear on the gearbox, it causes the output shaft to rotate at the speed of the engaged gear.

In this article, we’re going to discuss:

- Constant mesh gearbox construction:

- Constant mesh gearbox working:

- Double declutching in constant mesh gearbox:

- Advantages of constant mesh gearbox:

- Application of constant mesh gearbox:

- FAQ’s:

Constant mesh gearbox construction:

Constant mesh gearbox consists of the following key components:-

A) ENGINE SHAFT: The engine shaft has a clutch gear fixed on one end. Another end of the engine shaft is connected to the clutch. When the clutch engages, power receives at the Engine shaft from the Engine.

Clutch gear meshes (engages) with gear 5 on the lay shaft, hence power transmits from the engine shaft to the lay shaft.

B) LAY SHAFT: The lay shaft has 5 fixed gears (gear 1, gear 2, gear 3, gear 4, gear 5).

Lay shaft gears are constantly meshed with output shaft gears. Hence power transmits from the engine shaft to output shaft gears through lay shaft gears.

C) OUTPUT SHAFT:– It is a spline shaft. It has four gears ( gear A gear B, gear C, gear D ). These gears freely rotate on the output shaft using bearings.

There are two dog clutches on the output shaft. These dog clutches have internal splines hence they can easily slide on the spline of the output shaft and rotate with it.

- Read here: Synchromesh gearbox

E) OUTPUT SHAFT GEARS:-

These gears freely rotate on the output shaft. When the Dog clutch meshes with gears, power transmits from the engine shaft to the output shaft through the lay shaft.

F) DOG CLUTCH:-

The output shaft has two dog clutches. One is between Gear A and Gear B and another one is between Gear C and Gear D.

Dog clutches are internally splined, hence they can slide on the output shaft and rotate with it. When the dog clutch meshes with gears on the output shaft, power transmits from the engine shaft to the output shaft through the lay shaft.

G) GEAR SHIFTING MECHANISM:-

The gear-shifting mechanism is used to move dog clutches (either in the left direction or right direction) on the output shaft.

One end of this mechanism is connected to the gear pedal and another end is connected to dog clutches.

Therefore, when the driver shifts the gear pedal to achieve the desired gear, through the gear shifting mechanism, the dog clutches on the output shaft slides to mesh (engage) with output shaft gears.

H) GEAR PEDAL:-

The Gear pedal is connected to dog clutches through a gear-shifting mechanism.

I) IDLER GEAR:-

It is a Separate Gear used in this gearbox. The idler gear is used in the gearbox, to achieve reverse gear.

When the Gear on the lay shaft meshes (engages) with gears on the output shaft, both rotate in opposite directions, which means the vehicle runs frontward.

The purpose of using the idler gear is to change the direction of the output shaft to achieve the reverse gear.

Constant mesh gearbox working:

In a constant mesh gearbox, the gears on the lay shaft and output shaft are constantly meshed. In this gearbox gear ratios are obtained by moving the 2 dog clutches. Here we can obtain four different gear ratios.

In the neutral position, dog clutches do not mesh with any gear, hence output shaft gears freely rotate on the output shaft.

Based on the movement of dog clutches on the output shaft, four gear ratios can be obtained as follows:

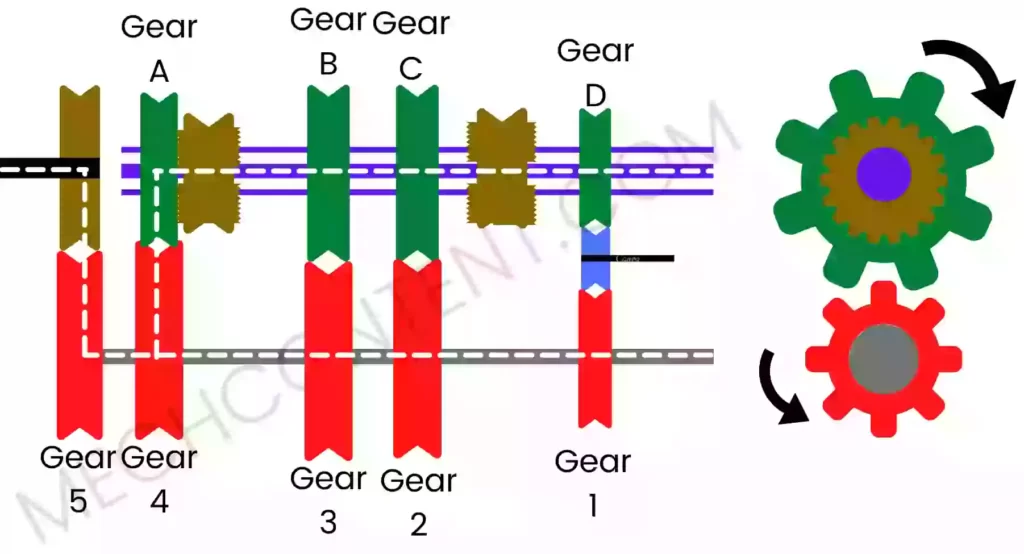

1] FIRST GEAR:-

When Dog Clutch 1 moves towards the left and meshes with gear A, the Dog clutch starts to rotate with gear A and it also rotates the output shaft.

Therefore In first gear, the power transmission takes place as follows:

Engine shaft -> Clutch gear-> gear 5->lay shaft->gear 4->gear A->output shaft

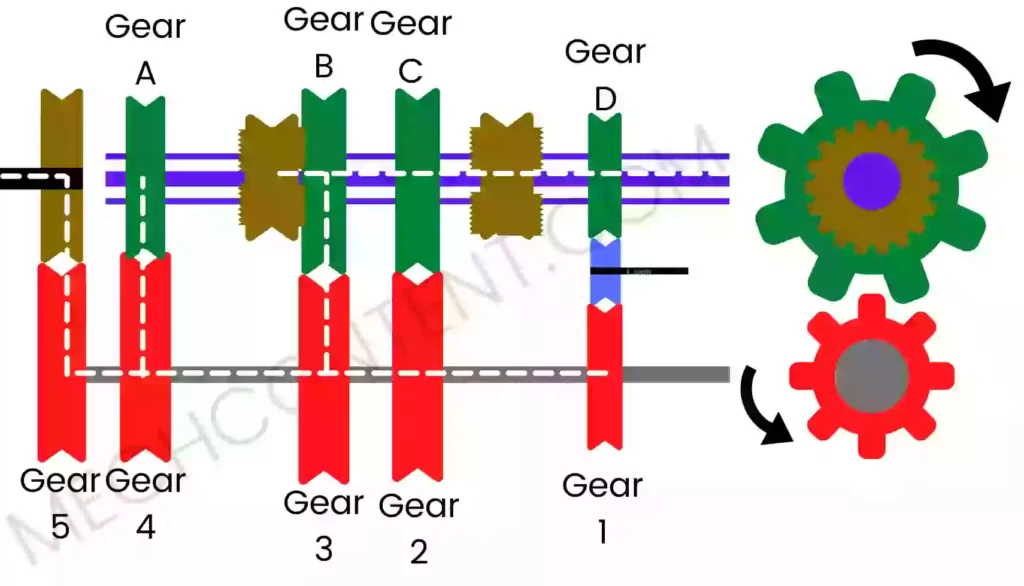

2] SECOND GEAR:-

When Dog Clutch 1 moves towards the right and meshes with Gear B, the Dog clutch starts to rotate with Gear B and it also rotates the output shaft.

Therefore In second gear, the power transmission is as follows:

Engine shaft -> Clutch gear-> gear 5->lay shaft->gear 3->gear B->output shaft

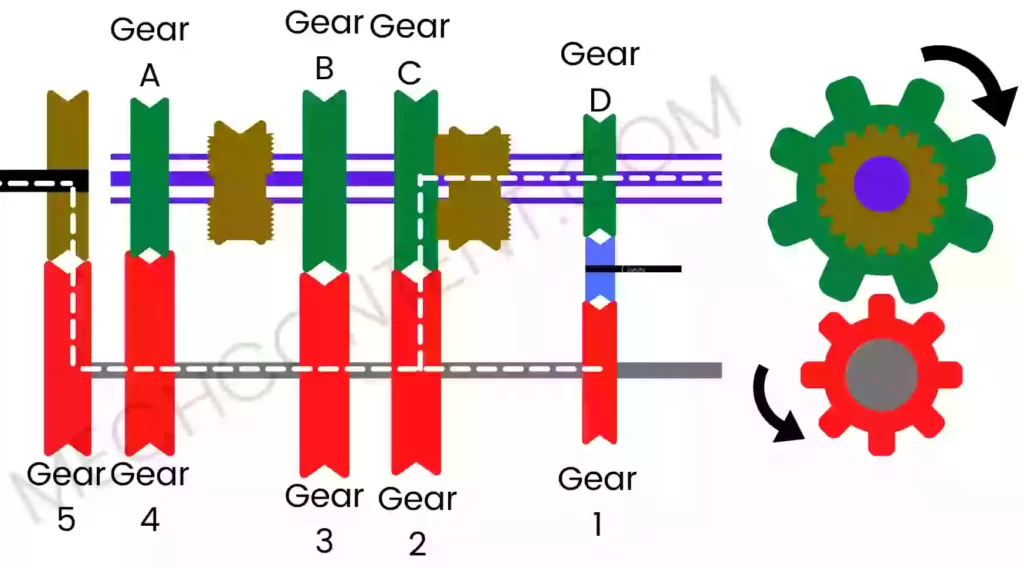

3] THIRD GEAR:-

When Dog Clutch 2 moves towards the left and meshes with gear C, Dog Clutch starts to rotate with gear C and it also rotates the output shaft.

Therefore in third gear, the power transmits as follows:

Engine shaft -> Clutch gear-> gear 5->lay shaft->gear 2->gear C->output shaft

4] REVERSE GEAR:-

When Dog Clutch 2 moves towards the left and meshes with Gear D, the Dog clutch starts to rotate with gear D and it also rotates the output shaft.

Therefore in reverse gear, the power transmits as follows:

Engine shaft -> Clutch gear-> gear 5->lay shaft->gear 1->Idler gear -> gear D->output shaft

Double declutching in constant mesh gearbox:

In a constant mesh gearbox for smooth engagement of the dog clutch and output shaft gears, it is necessary that the speed of both (dog clutch and gear) should be the same. For this purpose, while shifting the gear in such a gearbox double declutching is used.

Double declutching means to change/shift gear, the driver needs to press the clutch pedal two times.

Let’s see, how it is done with the help of the following examples.

Double declutching to change/shift gear from 3rd to 4th (Increase):-

- First clutch pedal is pressed.

- Shifting the gearbox from 3rd gear to a Neutral position.

- Clutch pedal is released.

- The driver needs to wait till the output shaft gear speed reduces to sufficient to mesh with the dog clutch.

- Again clutch pedal is pressed and the gear shifts from Neutral to 4th.

- Again clutch pedal is released. In such a way, gear shifts from 3rd to 4th by double declutching.

Double declutching to change/shift gear from 4th to 3rd (Decrease):-

- First clutch pedal is pressed.

- Shifting gearbox from 4th gear to Neutral position.

- Release the clutch pedal.

- Press the accelerator to increase the speed of the output shaft gears to match the speed of the dog clutch.

- Again press the clutch pedal then shift gear from neutral to 4th.

- Again release the clutch pedal. In such a way, gear shifts from 4th to 3rd by Double declutching.

Advantages of constant mesh gearbox:

The advantages of a constant mesh gearbox are as follows:-

- It is compact in size as compared to a sliding mesh gearbox.

- Smooth engagement.

- Silent in operation due to the use of helical and double helical gears.

Application of constant mesh gearbox:

Constant mesh gearbox was used in the following vehicles.

- Farmer trucks

- Two wheeler

- heavy duty machinery

FAQ’s:

-

Which types of gears are used in a constant mesh gearbox?

Helical types of gear are used in constant mesh gearboxes for power transmission.

-

What does constant mesh mean in the constant mesh gearbox?

Constant-mesh means the gear on the lay shaft and output shaft are constantly meshed (Engaged) with each other.

-

What is double declutching used for?

Double clutching is used for equalizing the speed of the dog clutch and output shaft gears for their smooth engagement.