Deep drawing is a combination of sheet metal operation and metal forming process. Let’s see more about it.

Contents:

What is Deep drawing?

Deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. This process is the combination of metal forming process and sheet metal process.

If the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. If the ratio is less, then it’s called shallow drawing.

`\frac{h}{d_{p}}\geq 0.5`

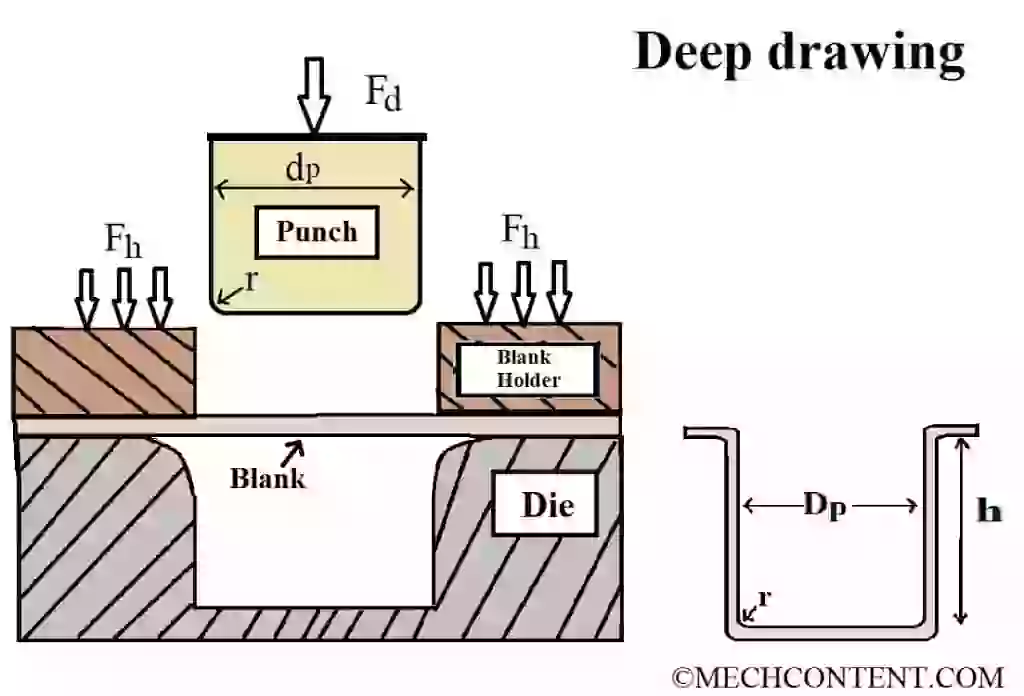

The setup used for this process, basically consists of die, punch, blank holders.

After the application of drawing force, the blank of material forms and takes shape of the punch or shape made onto the punch. To avoid frictional resistance between blank and die, the lubricant is used.

The applications of deep drawing process are kitchen utensils, cylindrical containers, fire extinguishers etc.

Construction:

The setup used for this process consists of following components:

1) Blank: It is a work-piece on which drawing operation is done. It is a blank/piece of sheet metal which is placed onto the die hole.

The diameter of the blank is denoted by Db and thickness is denoted by ‘t’. After application of drawing force, the material of blank form and take shape of punch.

2) Punch: Punch is used to apply drawing force on blank material. The shape of product depends upon the shape of punch.

The punch pushes the blank material into the die cavity. The diameter of the punch is denoted by Dp.

3) Die: It is generally made of cast iron or tool steel. The blank bend over the circular shape of the die.

The clearance between the die and punch should be enough to allow drawing and to avoid shearing failure in material. The corners of the die should have fillets to avoid shearing.

4) Blank holders: Blank holders are used to hold the blank onto the die surface by applying optimum force.

If the applied force is greater than the optimum limit, it results in shearing at die corners. And if it is lower thank optimum limit then it will result in wrinkling defect at flange surface of product.

The optimum holding force is one third of the drawing force.

`F_{h}= frac{F_{d}}{3}`

Working:

The process is making the products using deep drawing process is as follows:

The blank of sheet metal is placed onto the surface of the die. The blank holders hold the blank onto the die.

The punch moves downward into the die. Due to which, the blank material will form and take the shape of punch or shape on punch.

In some cases, single stroke drawing will not give required height to the product. Hence, in this case, drawing operation is done in number of stages.

Deep drawing calculation:

A] Diameter of blank (Db):

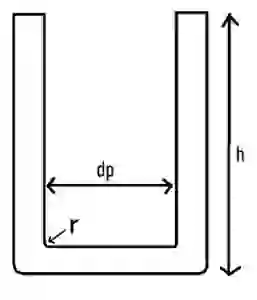

For cylindrical shape:

Here,

dp = Inner diameter of cylinder

h = height of cylinder

r = Corner radius

Considering surface area of blank and inner surface area of cup are equal.

One side surface area of blank = Inner area of cup

`frac{pi }{4}D_{b}^{2}= frac{pi }{4}D_{p}^{2}+pi d_{p}h`

`D_{b}= sqrt{d_{p}^{2}+4d_{p}h}`

For considering corner radius (r) the blank size is given by,

Case 1: When `frac{D_{p}}{r}geq 20`, The effect of corner radius is neglected.

`\mathbf{D_{b}= sqrt{d_{p}^{2}+4d_{p}h}}`

Case 2: When `15< frac{D_{p}}{r}< 20`

`\mathbf{D_{b}= sqrt{d_{p}^{2}+4d_{p}h}-0.5r}`

Case 3: When `10< frac{d_{p}}{r}< 15`

`\mathbf{D_{b}= sqrt{d_{p}^{2}+4d_{p}h}-2r}`

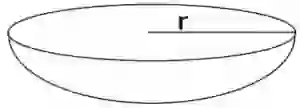

For hemispherical shape:

In this case, equating surface area of blank & hemisphere.

`frac{pi }{4}d^{2}= 2pi r^{2}`

`d_{b}= sqrt{8}r`

B] Maximum drawing force (Fd):

The maximum drawing force applied onto the punch for drawing operation is given by,

`F_{d}= pi d_{p}t+sigma _{ut} [ frac{D_{b}}{d_{p}}-0.7 ]`

Where,

dp = Punch diameter

t = Thickness of sheet

`sigma_{ut} ` = Ultimate tensile stress of blank material

Db = Diameter of blank

0.7 = Correction factor for friction.

C] Blank holding force:

The blank holding force should be sufficient to avoid wrinkling defect and to avoid shear failure. Generally, it equals to one third of drawing force.

`F_{h}= frac{F_{d}}{3}`

D] Clearance between die & punch:

The clearance between the die and punch should be optimum to avoid shear failure in the blank.

The clearance is 10% more than the thickness of sheet metal.

Clearance, (C) = (1.1) x t

Deep drawing defects:

The defects occur in material of blank are as follows:

A] Shearing: It is the shearing failure of blank material at corners of die and at corners of punch. It occurs when the stresses in blank material overcomes ultimate stresses.

B] Wrinkling/Earing: When the blank holding force is less than optimum holding force, then it will result in wrinkling of the collar of the product.

Advantages:

The advantages of deep drawing process are as follows:

- It is quick operation.

- Skilled operators are not required.

- It is a simple process.

- It requires less setup cost.

Application:

The applications of deep drawing process are as follows

- Kitchen utensils

- Cylindrical and hemispherical shaped containers.

- Fire extinguishers cylinders.

FAQ:

-

What is the difference between deep drawing and bar drawing?

Deep drawing is a sheet metal forming operation in which the blank of material is formed into cylindrical or hemispherical container, while bar drawing is a process of reducing the diameter of a cylindrical bar.

-

What is clearance in deep drawing?

Clearance is the distance between the die and punch, and it should be optimum to avoid shear failure in the blank.

-

How do you prevent wrinkles in a deep drawing?

To prevent wrinkles defect in deep drawing, the holding pressure onto the blank should be optimum.

-

What is the drawing ratio in deep drawing process?

It is the height (H) to Diameter (D) ratio of the product. If it is greater than 0.5 then this drawing operation is called deep drawing.

-

What is the cause of earing defect in deep drawing?

It occurs due to the presence of a gap between blank and blank holder. If the holding pressure is optimum, then this defect will not occur.

-

What are the primary defects of deep drawing operation?

The primary defects occur in deep drawing products are wrinkling/earing and shearing.

-

What is the importance of blank holding force in deep drawing operation?

The blank holding force is required to hold the blank onto the die surface. If the holding force, then it results in wrinkling defect. If the force is more than the required limit, then it results in shear failure at the corners.