What is a Disc brake system?

Disc Brake is one of the types of braking systems that uses rotor disc and brake (friction) pads. The rotor is mounted on the wheel, thus it rotates with the wheel. To stop the wheel the disc is clamped between the brake pads.

The friction between the disc and brake pads creates braking force for the vehicle to stop.

The disc brake is a compact system and requires less effort to stop the vehicle.

Nowadays, the disc brake system is found in a wide range of vehicles.

In this article, we’re going to discuss:

- Disc brake working principle:

- Disc brake construction:

- Disc brake working:

- Disc brake advantages:

- Disc brake System applications:

Disc brake working principle:

The disc brake system works on the principle of Pascal’s Law.

Pascal's law:- A Pressure at any point in a static fluid is equal in all directions.

We know that the pressure is the ratio of force to the area and oil pressure (P) in hydraulic lines is constant.

Thus for constant pressure P, as the bore area of the master cylinder decreases, the force required to press the brake pedal also decreases.

Similarly, for constant pressure P, at the brake caliper as the area of the piston at the brake caliper increases, the braking force applied on the disc also increases.

Thus due to the smaller bore of the master cylinder and larger brake caliper piston, fewer efforts on the brake pedal can generate higher braking force at the disc.

Disc brake construction:

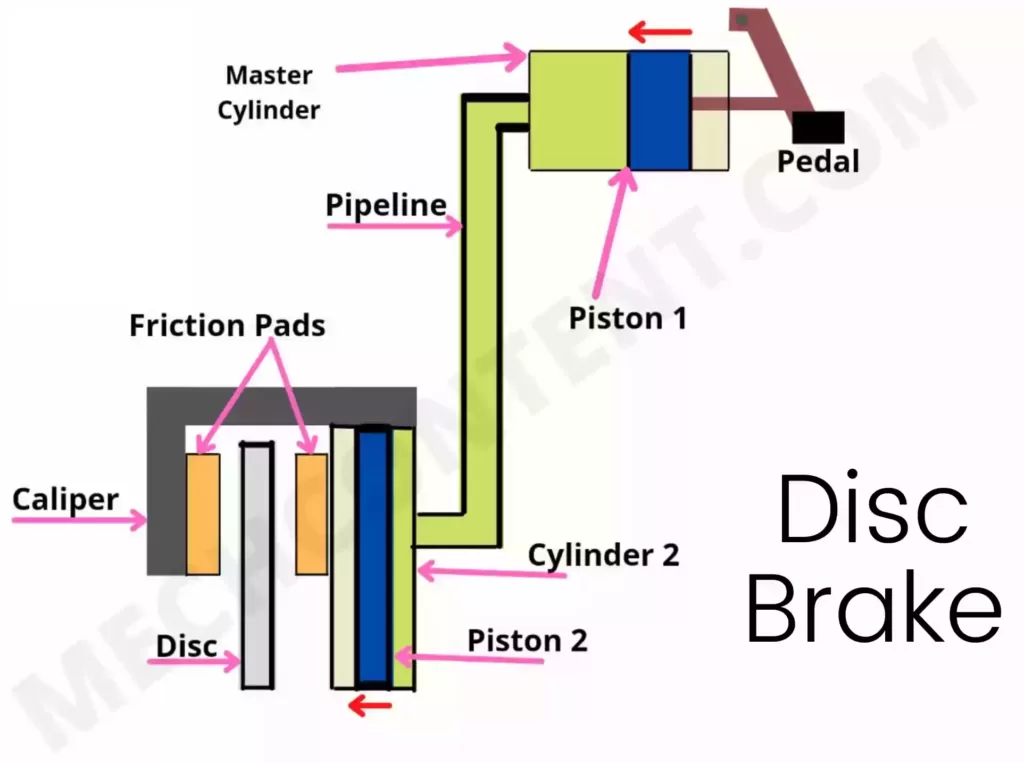

The below figure shows the basic structure of the disc brake system used in vehicles.

Following are the components of this braking system.

1) MASTER CYLINDER:- Master cylinder consists of piston 1 (see above figure), cylinder, reservoir, return spring.

The brake pedal is connected to piston 1. When the driver presses the brake pedal, the pressure is generated into the system brake fluid by piston 1.

2) FLUID RESERVOIR:- It is used to maintain the brake fluid level inside the system.

3) PIPELINE: A pipeline is used to flow the brake fluid from the master cylinder to cylinder 2. One end of the pipeline is connected to the master cylinder & another end is connected to cylinder 2.

4) DISC:- It is a circular metal disc. The disc is attached to the wheel hub. hence the disc also rotates with the wheel.

The disc has holes to dissipate the heat-generating during braking.

5) CYLINDER 2:- It consists of piston 2 (see above figure) to which the friction pad is attached. Therefore when the driver presses the brake pedal, due to pressure generated by piston 1, piston 2 moves forward & clamps the rotating disc.

6) CALIPER:- It is mechanism works in such a way that, when piston 2 presses the rotating disc, the caliper starts pressing the disc from the opposite direction. The caliper also has a friction pad to press the disc.

Disc brake working:

In a running vehicle, when the driver presses the brake pedal, piston 1 pushes the brake fluid. Therefore pressure is generated into the system brake fluid by piston 1.

The fluid flows from the master cylinder to cylinder 2 through the pipeline.

Due to brake fluid pressure, piston 2 moves and presses the friction pads over the rotating disc from one side & caliper also presses the friction pad over the disc from another side.

Hence due to the friction between both friction pads and the disc, the disc stops rotating and the vehicle stops.

When the driver releases the brake pedal, the pressure on the fluid gets removed. The return spring in the master cylinder pulls the fluid back to the master cylinder. Therefore piston and caliper come to their original position. Hence resulting in the brake getting released.

Disc brake advantages:

- Less braking time & braking distance.

- The heat generated is easily dissipated.

- Compact system

- Less effort is required to stop the vehicle.

Disc brake System applications:

The applications of the disc brake system are as follows:-

- Motorcycle

- Car

Read also: