The fuel injection pump is the heart of the fuel injection system in the diesel engine. For the proper combustion in the diesel engine, the fuel injection pump performs a vital role. Thus, in this article, we are discussing the fuel injection pump.

In this article, we’re going to discuss:

- What is Fuel injection pump?

- What is the function of fuel injection pump?

- Types of fuel injection pump:

3.1. Inline fuel injection pump:

3.2. Distributor fuel injection pump:

3.3. Continuous fuel injection pump: - How to tell if fuel injection pump is bad?

- What is phasing and calibration of fuel injection pump?

What is Fuel injection pump?

Fuel injection pump (FIP) is the device used in the diesel engine for pumping the fuel to the injectors and it also helps to distribute and meter the supply of fuel to all injectors.

The other function of the FIP is to pump the correct quantity of fuel at the right time (Just before the piston reaches TDC during compression stroke) and within a specified duration.

Along with this, some fuel injection pumps also help to distribute the fuel to all the cylinders of the multicylinder engine as per their firing sequence.

In ECU-controlled vehicles, the fuel injection pump is only used to pressurize the fuel line as the distribution of fuel is controlled with the help of electric injectors and ECU units.

In an IC engine, Fuel injection pump is driven with the help of a crankshaft or by the camshaft.

What is the function of fuel injection pump?

Following are some of the major functions of the fuel injection pump:

1] Pumping fuel at high pressure: It is the main function of it. The fuel injection pump draws fuel from a fuel tank and pumped it at high pressure to all injectors.

In an electronic fuel injection system, the fuel injection pump is used only for pressurizing the fuel line.

2] Metering of the fuel: The inline fuel injector pump helps to control the amount of fuel to be supplied to the injector.

3] Distribution of fuel: This is another important function of the fuel injection pump, to distribute the fuel to all the injectors at the exact time.

In inline fuel injection, the separate plunger and fuel barrel for each engine cylinder are used to supply fuel to all the injectors. In the distribution pump, the rotor helps to distribute fuel to all the cylinders.

4] Cooling of fuel injectors: The fuel injectors are directly subjected to the combustion process, thus the fuel injectors are subjected to a higher temperature. By pumping the low-temperature fuel into the injector, the fuel injection pump helps for the cooling of the fuel injectors.

Types of fuel injection pump:

Following are the different fuel injection pumps used in diesel engines:

- Inline fuel injection pump

- Distributor fuel injection pump

- Continuous fuel injection pump

Let’s see how each one of the above FIPs works.

Inline fuel injection pump:

The inline fuel injection pump uses a plunger and fuel barrel to pump the fuel. The pump uses the number of plungers equal to the number of fuel injectors and all are arranged in the same line.

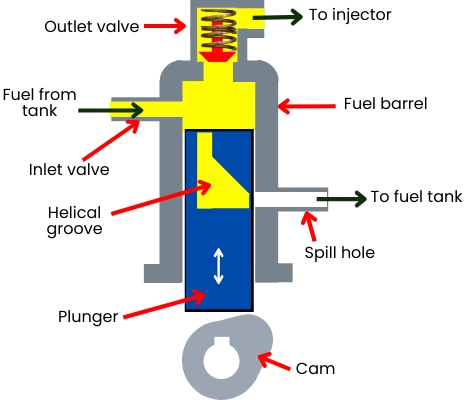

The schematic diagram for the inline fuel injection pump is shown below.

The inline fuel injection pump consists of the following major components:

- Plunger with a helical groove

- Fuel barrel

- Inlet valve

- Spill hole

- Outlet valve

The camshaft arranged below the plunger helps to reciprocate the plunger inside a fuel barrel.

The camshaft gets power from the engine crankshaft and it operates in such a way that the fuel will be injected at an exact time and for the exact duration.

When the plunger moves downward, the fuel is sucked inside a barrel through an inlet valve.

During the upward stroke, the plunger develops pressure on the fuel trapped inside a barrel.

This high-pressure fuel pushes the outlet valve against the spring to open and then the fuel moves to the injector.

The amount of fuel supplied is controlled with the help of a spill hole, a helical groove on the plunger, and a rack and pinion arrangement.

Distributor fuel injection pump:

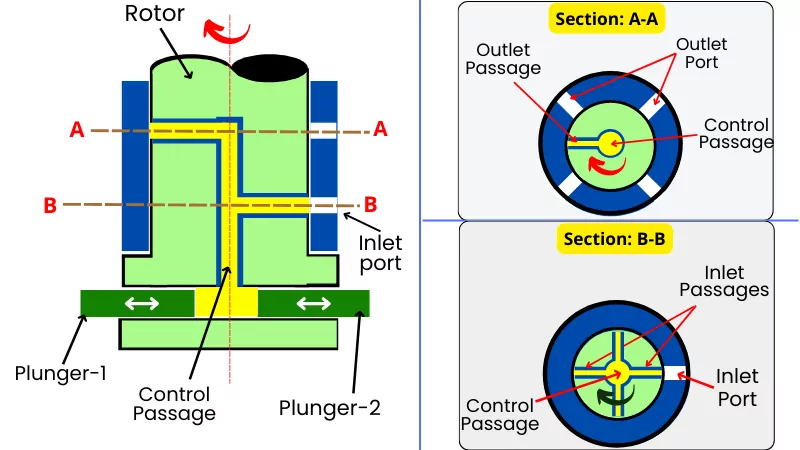

The distributor type pump uses a single pumping mechanism and uses a rotary distributor to distribute fuel to the multiple injectors. The schematic diagram of the distributor fuel pump is shown below.

As shown in the above figure, the distributor fuel injection pump consists of the following main components:

- Rotor with control passage

- Stator or body with inlet and outlet ports

- Two reciprocating plungers

The rotor of the distributor pump has vertical internal (control) passage. The rotor also has a number of suction passages and one discharge passage. The suction and discharge passage are made at different elevations.

The stator body of the distributor pump has a single suction port and a number of discharge ports.

The number of discharge ports in the stator body is equal to the number of fuel injectors in an engine. The rotor rotates inside a stationary body for the distribution of fuel.

When the suction port is aligned with the suction passage of the rotor, both plungers move away from each other, thus the fuel is sucked into the control passage.

When the discharge port aligns with the discharge passage, the plungers move toward each other. Thus the fuel inside a control passage is injected into the discharge ports. In this way alternately the rotor supplies fuel to all fuel injectors.

The plungers reciprocate inside a cylinder by use of the cam ring and it can deliver the fuel at a higher engine speed.

Continuous fuel injection pump:

The continuous pump helps to maintain pressure on the fuel lines. Unlike other pumps, it is not used to distribute or meter the quantity of the fuel.

It is used in an electronic fuel injection system, where the ECU controls the fuel injection.

How to tell if fuel injection pump is bad?

Some of the faulty fuel injection pump symptoms are as follows:

1] Engine splutters: The improper fuel injection because of the faulty fuel injection pump is one of the reasons for the sputtering noise of the engine. One can notice this sputtering noise while accelerating the vehicle or at a higher engine speed.

2] Whining noise: This is another symptom that you can hear a whining noise made by the fuel pump at the location of the fuel tank.

It may arise due to the faulty fuel injection pump or it may cause due to the insufficient amount of fuel in the tank, thus it becomes difficult for the pump to suck the fuel.

3] Lack of power when a vehicle is loaded: In some cases when the vehicle is in loaded condition, the fuel pump is not able to provide a sufficient amount of the fuel for the combustion, thus it feels like the engine is unable to produce a sufficient amount of power to move the load.

4] Difficult to start: Sometimes it becomes difficult to start the engine, as the fuel pump is not pressurizing the fuel line. In some cases, the engine gets started, and then it again stalls.

5] Smoky exhaust and less fuel economy: One of the reasons behind the smoky exhaust is that the fuel pump is supplying excessive fuel to the injectors.

Thus due to the improper combustion of the fuel, smoky exhaust gases are observed at the tailpipe or the fuel economy gets lowered.

What is phasing and calibration of fuel injection pump?

Phasing of the fuel injection pump is the procedure of adjusting the fuel injection timing to reduce the torque fluctuations. The phasing of the fuel injection pump is generally done before the calibration.

The timing of the fuel injection is adjusted with respect to the position of the crankshaft. The phasing helps to reduce the torque fluctuation; thus it also reduces the gear impact noise.

Calibration of the fuel injection pump is carried out to ensure the same quantity of fuel is delivered to all the cylinders of the multicylinder engine. The calibration is generally done after the repairing or rebuilding of the fuel injection pump.

FAQs:

-

What does a fuel injection pump do?

The fuel injection pump has following functions:

Pumps the fuel to all the injectors at high pressure

Control the quantity of fuel to be supplied

Distribute the fuel to all injectors -

What are the signs of a failing injector pump?

Following are some of the signs of a failing injector pump:

1] Spluttering noise from the engine

2] Whining noise near the fuel tank

3] Difficulty while starting the engine

4] Smoky exhaust