What is Pneumatic braking System?

The pneumatic braking system is one of the types of Automobile Braking System. This system uses compressed air for the actuation of the brake shoe for applying the brake.

It is also known as the Air braking system. It was invented by George Westinghouse in the 1860s.

The pneumatic brake is used in heavy vehicles. as the brake force produced by the hydraulic brake is not sufficient to stop the heavy vehicles.

The five basic components of a pneumatic or air brake system are the air compressor, storage tank/air reservoir, brake valve, brake chamber, and brake drum.

In this article, we’re going to discuss:

- Construction:

- How does the pneumatic braking system work:-

- Advantages of Pneumatic braking system:

- Disadvantages of pneumatic braking system:

- Applications of pneumatic braking system:

Construction:

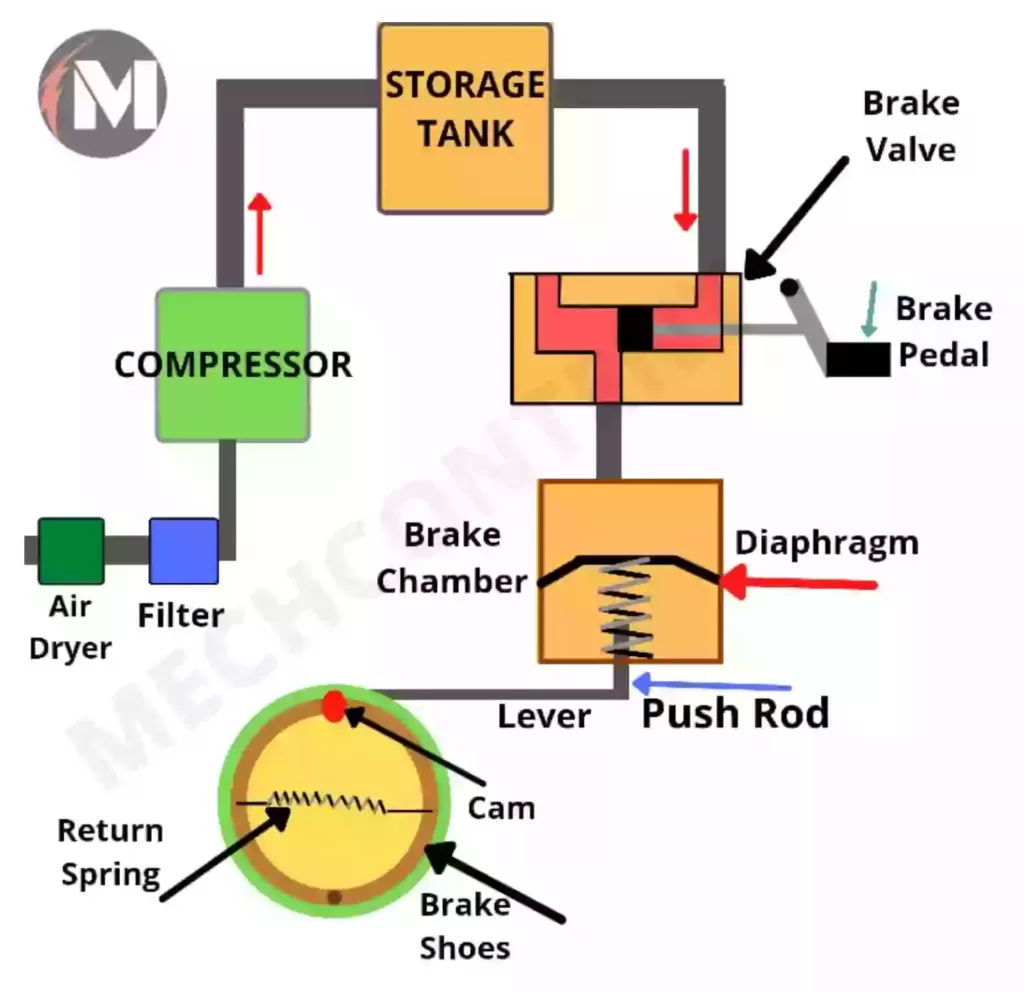

The below figure shows the basic structure of pneumatic braking.

It consists of the following components:-

1) Air Compressor: The compressor works on the engine power. The role of the compressor is to take air from the atmosphere, compress it, and send it to the storage tank.

2) Air Filter: An air filter is used before the compressor to remove the dust particles from the air, before entering into the compressor.

3) Air Dryer:- Air dryer is used before the compressor to remove the moisture from the air, before entering into the compressor. This is because the moisture can damage the compressor blades.

4) Storage Tank:- It stores the compressed air received from the compressor.

5) Safety valve / Pressure Regulator valve:- This valve is used on the storage tank to maintain the pressure inside the tank and to remove the excessive air from the tank.

6) Brake Valve:- This is used to regulate the airflow from the storage tank to the brake chamber.

It is controlled by the brake pedal. When the driver presses the brake pedal, the brake valve opens, Therefore air flows from the storage tank to the brake chamber.

When the driver releases the brake pedal, the brake valve closes, Therefore air stops flowing from the storage tank to the brake chamber.

7) Brake Chamber:- It consists of the diaphragm, and return spring. The diaphragm is connected to the push rod & the push rod and lever and the lever is connected to the cam.

When the driver releases the brake pedal, the return spring returns the diaphragm to its original position.

8) Brake Drum:- It consists of two brake shoes, a cam, return spring. One end of both shoes is hinged and the other ends are connected to the cam.

When the cam rotates, the brake shoes expand inside the brake drum.

The outer surface of the brake shoes has a friction lining. Therefore when the brake shoes expand, due to friction between the shoes and brake drums, the wheel stops.

The shoes are connected with the return spring. Therefore when the driver releases the clutch pedal, the shoes come to their original position due to the spring tension.

How does the pneumatic braking system work:-

When the engine starts the compressor starts feeding air to the reservoir to maintain the required pressure in the storage tank.

Let’s understand, how this system works during applying the brake and releasing the brake

When Brake applied:-

When the driver presses the brake pedal, the brake valve opens, and the air flows from the storage tank to the brake chamber.

In the brake chamber, the air pushes the diaphragm, which causes the push rod to move out. Then the push rod actuates the adjustable lever to rotate the cam.

While rotating, the cam pushes the brake shoes out to expand inside the brake drum. Due to friction between the shoes and the brake drum, the wheel stops.

When Brake release:-

When the driver releases the brake pedal, the brake valve closes. Hence, the air stops flowing from the storage tank to the brake chamber.

The return spring pushes the diaphragm to its original position. Through the push rod and adjustable lever, the cam again rotates in the opposite direction to come to its original position.

Due to cam movement, the spring pulls the shoes inside. Hence again the wheel starts rotating.

Advantages of Pneumatic braking system:

- It is faster in operation than Mechanical & Hydraulic Brake.

- Less braking distance and braking time.

- It requires less effort.

Disadvantages of pneumatic braking system:

- It has a noisy operation.

- Possibility of air leakage, which may result in braking failure.

- It has a high maintenance cost.

Applications of pneumatic braking system:

It is used in a heavy-duty vehicles, where higher braking force is required. Below of some of them:-

- Trucks

- Bus

- Air Brake System in Train.

Read also: