Modern IC engines adopt a variety of techniques to enhance power production, decrease energy losses, and improve efficiency. Turbocharging is one of these techniques that helps to meet all the above requirements.

It helps to increase the power developed by the engine, recovers part of the energy from the waste exhaust gases, and increases the overall efficiency of the engine.

Thus in this article, we are going to discuss turbocharging in IC engine in detail.

In this article, we’re going to discuss:

- What is Turbocharging in IC engine?

- Turbocharger working principle:

- Turbocharger function:

- Turbocharger parts:

- How turbocharger works?

- What is turbo lag?

- How many types of turbocharger are there?

- What are the advantages and disadvantages of turbocharger?

What is Turbocharging in IC engine?

Turbocharging is the process of increasing the power output of the IC engine by forcing the extra compressed air into the intake manifold of the engine with the help of a turbocharger that runs on the kinetic energy of the exhaust gases. Thus the engine can burn extra fuel and develop more power than the same sized naturally aspirated engine.

A turbocharger is a turbine-driven compressor that recovers energy from the exhaust gas and utilizes it to power a compressor that delivers additional compressed air into the combustion chamber of the engine.

It feeds compressed air into the cylinder thus it increases the amount of O₂ molecules fed to the engine. Then by supplying more fuel the engine develops a higher amount of power. Thus the turbocharger helps to increase the power developed by the engine and to enhance its performance.

Like a supercharger, it never uses the power of the crankshaft to run the compressor. It uses the kinetic energy of the exhaust gases to run the compressor. Thus it helps to recover the energy from the exhaust gases and increases the overall efficiency of the engine.

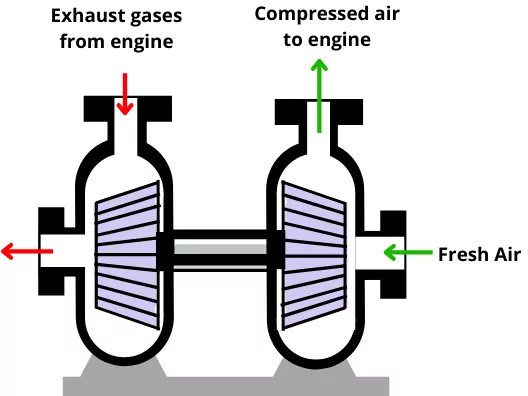

The turbocharger comprises two different components in a single unit which is the turbine and the compressor. Both compressor and turbine are mounted on the same shaft thus the power developed by the turbine is used to run the compressor.

What is the purpose of a turbocharger?

The naturally aspirated engine uses air at the atmospheric pressure as intake. Thus the engine uses a fixed amount of oxygen molecules and a fixed amount of fuel for combustion. It limits the power generation per power stroke of the engine.

The turbocharger helps to feed highly compressed air into the engine cylinder. The highly compressed air has a higher concentration of oxygen molecules.

By feeding this highly compressed air into the cylinder, the total mass of the oxygen fed to the cylinder increases. Thus by charging more fuel, the engine generates a higher amount of power.

Thus for the same size, the turbocharged engine generates higher power than the naturally aspirated engine.

Other than this the turbocharger uses the energy of the exhaust gases to run the compressor. Thus it increases the overall efficiency of the engine.

Turbocharger working principle:

The turbocharger uses the energy of the exhaust gases to feed the compressed air to the intake manifold of the engine. For this purpose, it uses two different components mounted on the same shaft which are a turbine and compressor.

The turbine utilizes some part of the kinetic energy of the exhaust gases to rotate the turbine shaft. As the shaft of the turbine and compressor are the same, the rotor of the turbine helps to rotate the rotor of the compressor.

Thus by using the exhaust gases, the turbocharger helps to feed the compressed air into the engine intake manifold.

Turbocharger function:

Following are the important functions of the Turbocharger for turbocharging in Internal Combustion engine:

1] Supplies compressed air to the engine:-

The turbocharger compresses air at high pressure to increase its density. By supplying this compressed air to the engine, the engine adds more fuel and develops more power. Thus the turbocharger provides a boost to the engine.

2] Recovers energy from exhaust gases:-

The turbocharger uses the kinetic energy of the waste exhaust gases to run the turbine. Thus it recovers some amount of energy from the exhaust gases and helps to increase the overall efficiency of the engine.

Turbocharger parts:

The turbocharger consists of the following important components:-

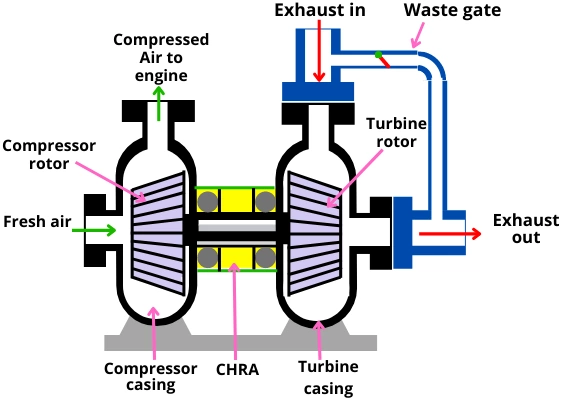

1] Turbine casing:-

The role of the turbine casing is to guide the flow of exhaust gases over the turbine blades thus the exhaust gases can rotate the blades of the turbine.

The casing of the turbine is consist of a single scroll or the twin scroll. In a single scroll casing, the exhaust pulses of the different cylinders can interfere with each other and reduce their strength.

The twin scroll casing has two scrolls or channel that helps to avoid the interference of the exhaust waves.

2] Turbine wheel/ rotor:-

The exhaust gases are passed over the blades of the turbine rotor. The high-velocity exhaust gases lose some amount of kinetic energy to move the rotor blades. Thus the rotor can achieve higher speed up to 1,00,000 rpm.

Due to the high exhaust temperature, the turbine rotor and casing are subjected to higher thermal stresses.

3] Wastegate:-

The wastegate helps to control the flow of exhaust gases entering the turbine.

At lower speed, the wastegate remains closed, but when the engine runs at higher speed, the higher flow of exhaust gases can Overspeed the turbocharger.

But during the higher speed, the wastegate becomes open and transfers the excess amount of exhaust gases further without entering into the turbine. Thus it helps to avoid the Overspeed of the turbocharger.

4] Compressor wheel/rotor:-

The compressor rotor is mounted on another side of the same shaft on which the turbine rotor is mounted. Thus the compressor rotor also starts to rotate along with the turbine rotor.

5] Compressor casing:-

The compressor casing helps to guide and compress the fresh air. The suction end of the compressor casing is connected to the air filter and the discharge end is connected to the intercooler.

6] CHRA (Center housing rotating assembly):-

The CHRA is the major component of the turbocharger that supports the bearing and shaft of the turbocharger.

How turbocharger works?

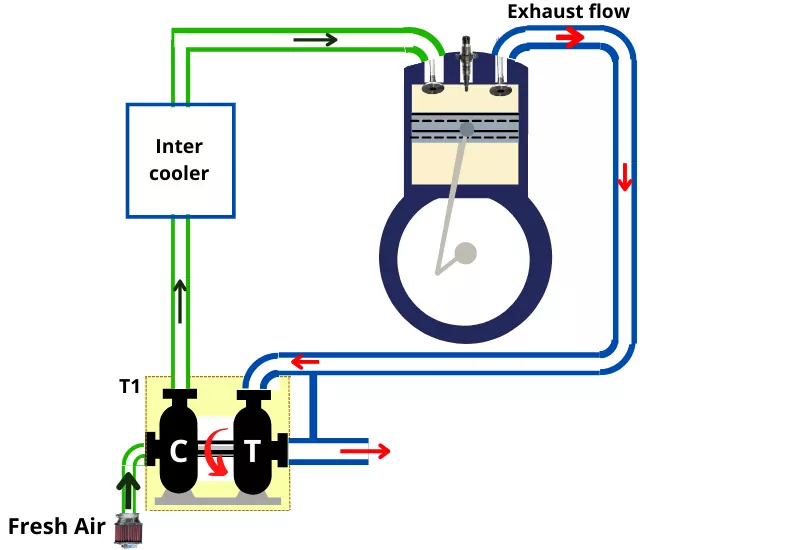

The turbocharger works as follows to boost the engine:-

1] As shown in the above figure, the exhaust gases from the engine enter the casing of the turbine. The scroll of the casing directs the exhaust gases flow over the turbine blades.

2] Here the exhaust gases lose some amount of energy to rotate the turbine rotor. The exhaust gases can rotate the turbine rotor up to 30 times the engine speed.

3] The compressor and turbine of the turbocharger have a common shaft thus the rotor of the compressor also starts to rotate along with the turbine rotor.

4] As the compressor starts to rotate, it draws clean air from the air filter at atmospheric pressure and compresses it above the atmospheric pressure to increase its density.

5] Due to the compression, the temperature of the air gets increases thus after compression the air is passed through the intercooler to lower the temperature of the air.

6] Then this highly compressed air is fed into the intake manifold of the engine.

7] The turbocharger also uses a waste-gate to bypass the exhaust gases at higher engine speed.

At higher engine speed, the higher flow of exhaust gases can Overspeed the turbocharger thus it can damage the turbocharger and engine components.

The wastegate controls the flow of exhaust gases entering the turbine and avoids the Overspeed and bursting of the turbocharger.

What is turbo lag?

Turbo lag is the time period between pressing the accelerator pedal and feeling a sudden power boost from the engine (Because of the turbocharger).

Turbo lag occurs because the exhaust gases at the lower engine speed are not sufficient to run the turbocharger. After pressing the accelerator pedal, the engine takes time to build a sufficient amount of exhaust pressure to run the turbocharger. This time taken for running the turbocharger is known as turbo lag.

Mostly the vehicles use single large turbochargers to meet power requirements at a higher engine speed. Therefore at lower engine speed, the exhaust flow is not sufficient to spool the rotor of such a turbocharger. To avoid these difficulties, the engine uses different arrangements of turbochargers so that the turbo lag gets lowered.

How many types of turbocharger are there?

Based on the construction and the arrangement, the turbochargers have the following different types:-

1] Single turbocharger:-

It is a simple type of turbocharging that uses a single turbocharger with a single scroll casing.

It provides a boost for the smaller RPM range and hence it has longer turbo lag than other types of turbochargers.

2] Twin turbocharger:-

In this, the engine uses two turbochargers for forcing more air into the intake manifold.

This type of turbine helps to avoid the drawback of using a single turbocharger. Instead of using a large-size single turbocharger, it uses two turbochargers of different sizes, thus it can run at a lower RPM also.

The twin turbochargers are classified further on the basis of their arrangements as follows:-

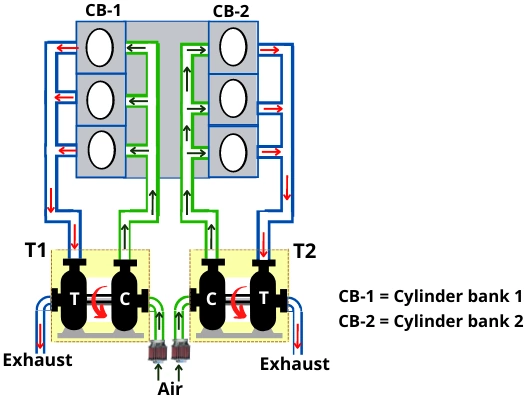

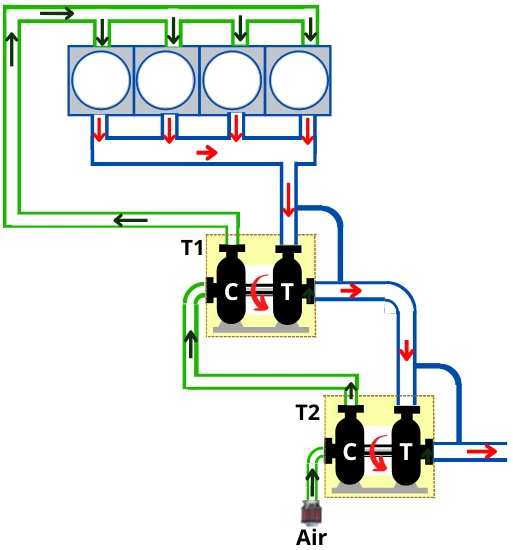

A] Parallel twin turbocharger:-

The parallel arrangement of the twin-turbo is used in V-engines. The engine uses a separate turbocharger for each cylinder bank. As shown in the above figure, the exhaust gases of the left cylinder bank (CB-1) is used to rotate the T1 turbocharger, and air compressed by its compressor is fed to all cylinder of the cylinder bank CB-1.

Similarly, the exhaust of the cylinder bank (CB-2) is used to rotate the T2 turbocharger, and the air compressed by its compressor is fed to all cylinders of the cylinder bank CB-2.

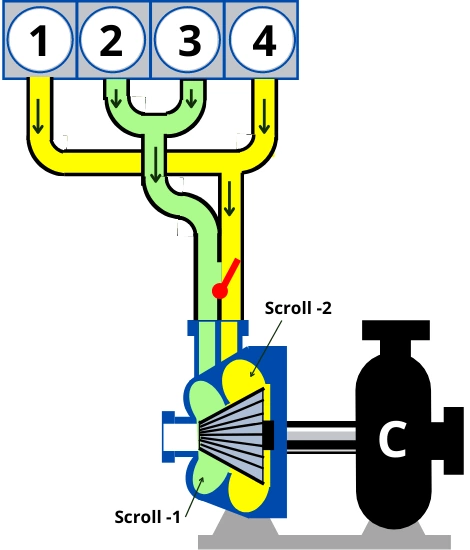

B] Sequential twin turbocharger:-

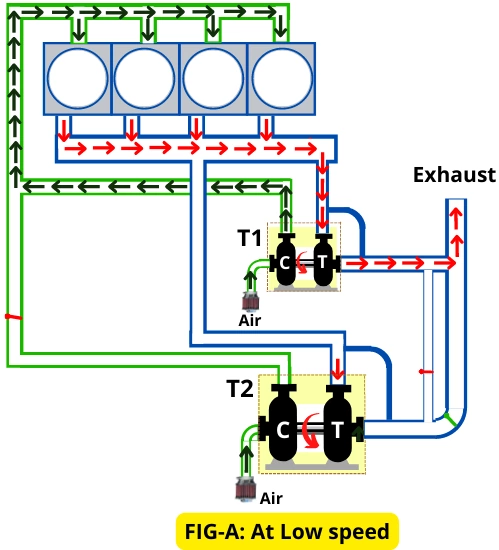

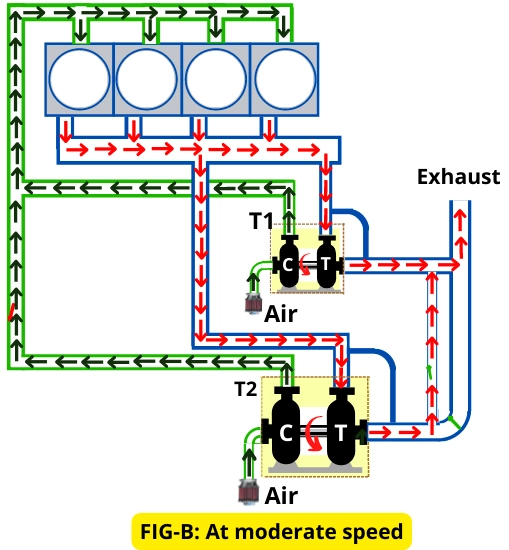

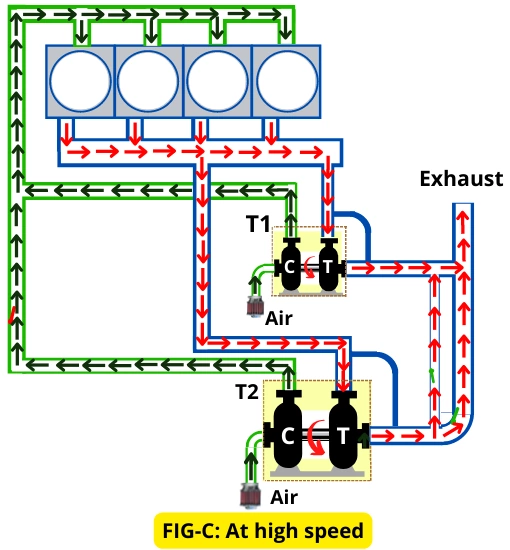

The sequential twin turbocharger uses one smaller turbocharger (T1) for lower engine speed and another bigger turbocharger (T2) for the higher engine speed. This arrangement of the turbocharger helps to reduce the turbo lag.

During the lower engine speed, a small turbocharger (T1) spools earlier and starts feeding compressed air in the intake manifold. And when the engine runs at a higher speed, the larger turbocharger (T2) starts to spin and increases the flow of compressed air to meet the high power requirement.

The below figure-A shows the turbocharger condition during lower engine speed when only a smaller turbocharger (T1) is running to feed the compressed air.

As shown in figure-B, at moderate engine speed, the larger size turbocharger (T2) is allowed to run at a slower speed along with the smaller turbocharger (T1).

Figure-C shows that during high engine speed, the larger size turbocharger (T2) is allowed to spin faster along with the smaller turbocharger (T1). Thus both turbochargers run together to meet the higher requirements of compressed air for the engine.

C] Series twin turbocharger:

In this arrangement of twin turbochargers, the compressed air output of one turbocharger is compressed by another turbocharger to supply highly compressed air to the engine.

The below figure shows a basic diagram for the series twin turbocharger.

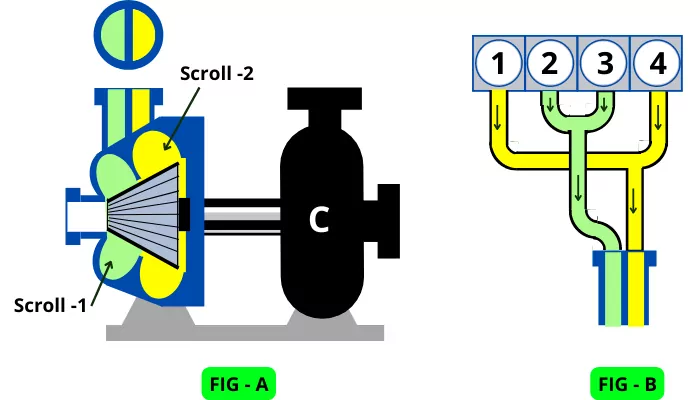

3] Twin scroll turbocharger:-

| Why twin scroll turbocharger? During the exhaust stroke, high-pressure waves are generated that are also known as exhaust pulses. The exhaust gases from each cylinder have to travel at different lengths from the exhaust port to the turbine inlet. Thus due to the uneven length of an exhaust manifold for each cylinder, the exhaust pulses developed by two consecutively fired cylinders can interfere with each other. This leads to the decreasing strength of the exhaust pulses. It also opposes the scavenging of these cylinders. The twin turbocharger separates the consecutive exhaust pulses thus they can’t interfere with each other. For the four-cylinder engine, if the firing order is 1-3-4-2 then the exhaust pulses of 1 and 3 can interfere with each other (Similarly for cylinders 3 & 4, 4 & 2, 2 & 1). Thus in the twin scroll turbocharger, the exhaust of cylinders 1 and 4 are connected to the one scroll/channel of the turbine, and the exhaust of cylinders 3 and 2 is connected to the other scroll of the turbine. Therefore the consecutive exhaust pulses get separated into the two different scrolls. Hence they do not interfere with each other and the maximum energy of the exhaust pulses gets utilized to move the turbine of the turbocharger. |

As shown in the above figure, the twin scroll turbocharger has two different scrolls or channels into the casing.

For the 4-cylinder engine having a firing order of 1-3-4-2, the exhaust of cylinders 1 & 4 is connected to the larger scroll (Scroll-2) and the exhaust of cylinders 2 & 3 is connected to the smaller scroll (Scroll-1).

The exhaust gases through smaller scroll hit the lower end of the rotor blades of the turbine to give the better performance during acceleration of the engine.

The exhaust gases through a larger scroll hit the upper end of turbine blades to spool the turbine at a higher speed.

The different sizes of the scroll work like two different sizes of turbochargers. Thus it can spool at lower as well as higher engine speeds. As well as it reduces the complexity of using two different turbochargers.

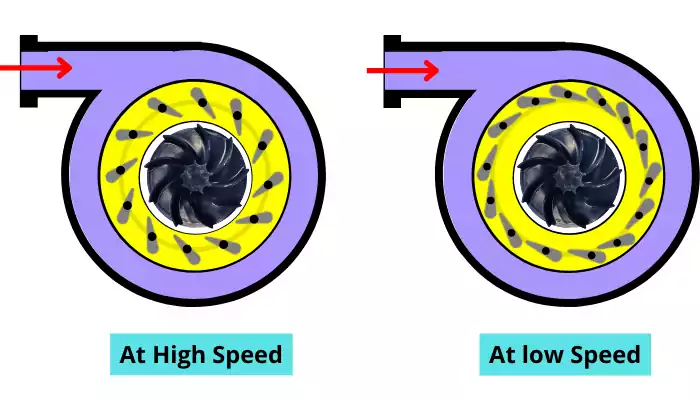

4] Variable geometry turbocharger:-

The variable geometry turbocharger is also abbreviated as VGT. The VGT uses a number of stationary vanes surrounded to the turbine rotor that changes the angle to control the flow of exhaust gases over the moving blades.

The opening between two adjacent vanes acts as nozzles and it is controlled by changing the vane angle. Thus as the angle of vanes changes, the pressure ratio of the opening between vanes also changes.

The variable geometry turbocharger works as follows:-

1] At lower engine speed, the flow of exhaust gases is insufficient to spin the turbine rotor. Thus at a lower speed, the vanes of the VGT come closer to decrease the opening between them and increases the pressure ratio.

After passing the exhaust gases through the vanes, the velocity of the exhaust gases increases and creates an impact on the turbine blades. Thus the turbine of the turbocharger can rotate to provide the required amount of boost at less engine speed.

2] At higher engine speed, the smaller turbocharger can Overspeed or the exhaust flow can get chocked.

To overcome these difficulties at high engine speed, the vanes of the turbine move away to increase the opening between them. It decreases the pressure ratio across the vanes opening, therefore the exhaust gases can pass over the turbine blades with less pressure. Thus it avoids the overspeeding of the turbocharger.

Thus according to the engine speed, the opening between the vanes gets adjusted and thus this turbocharger can provide a boost for a large range of engine speeds. Thus by using variable geometry turbochargers, the engine doesn’t require another auxiliary turbocharger.

As this turbocharger provides a boost for the larger speed range, it has less turbo lag than other turbochargers.

5] Variable twin scroll turbocharger:-

The variable twin scroll turbocharger is the combination of the variable geometry turbocharger and the twin scroll turbocharger. It comprises the advantages of a variable geometry turbocharger and a twin scroll turbocharger.

The variable twin scroll turbocharger uses a valve that controls the flow of exhaust gases in two scrolls of the turbine.

At low engine speed, the valve restricts the entry of the larger scroll-2. thus the exhaust gases only enter the smaller scroll-1 and passed over the smaller end of the turbine blades. Thus it provides a boost at low engine speed.

As the engine speed increases, the opening for the larger scroll also increases, and the flow of exhaust gases from cylinders 1 and 4 into the larger scroll-2 also increases. Thus the larger scroll-2 along with the smaller scroll-1 help to run the turbocharger. This helps to provide a boost at higher engine RPM.

At the higher engine speed, the valve fully opens the opening of the larger scroll-2, thus the exhaust gases from cylinders 1 and 4 enter into the larger scroll-2, and exhaust gases from cylinders 2 and 3 enter into the smaller scroll-1, thus both the scrolls are operated by separate exhaust lines. Hence at higher speed, the turbo operates at its high capacity.

6] Electric turbocharger:-

The electric turbocharger is used to avoid turbo lag during the lower engine speed.

At lower engine speed, the turbochargers are not able to spool the compressor of the turbine. To overcome these difficulties, these kinds of turbochargers have an electric motor attached that helps to run the turbocharger during the lower engine speed until the exhaust flow becomes able to run the turbine of the turbocharger.

Thus it helps to avoid the turbo lag and provides the boost for the broad range of the engine speed.

What are the advantages and disadvantages of turbocharger?

Turbocharging in ic engine advantages:-

The turbocharging in ic engine has the following advantages:-

- By using a turbocharger, more power/torque is obtained from the same swept volume.

- It decreases the size of the engine for the unit amount of power generation.

- It lowers the emission of harmful gases into the environment.

- It increases the overall efficiency of the engine.

- Provides better fuel economy.

- It partly recovers energy losses from exhaust gases.

Turbocharging in ic engine disavantages:-

The turbocharging in ic engine has the following disadvantages:-

- The turbocharger takes more space and it’s bulky.

- The turbocharger forcefully supplies the high compressed air which causes wear and tear of the engine and hence it reduces the life of the engine and increases the maintenance cost.

- It requires regular maintenance.

- It requires frequently oil replacement as it is subjected to higher temperatures.

- It is not suitable for single-cylinder engines as the flow of exhaust gases is not sufficient to run the turbocharger.

- It requires skilled personnel for its maintenance.

FAQs:

-

What is the working principle of turbocharger?

The turbocharger uses the energy of the exhaust gases to run the compressor which helps force the compressed air into the intake manifold.

-

What are the effects of turbochargers in IC engines?

The turbocharger forces more air into the engine, thus it helps to increase the power output, overall efficiency, and fuel economy.

-

How does a turbocharger affect performance?

The turbocharger increases the mass flow of oxygen into the intake manifold, thus the engine can burn more fuel to develop more power.

-

Where is turbocharger mounted?

The turbocharger is mounted after the exhaust manifold.

-

Do turbochargers increase fuel economy?

Yes, the turbochargers help to increase the fuel economy of the engine.

Final words:

Thus turbocharging in IC engine is a great invention in the history of the internal combustion engine that made the engines more efficient and powerful. It fulfills the need for extra horsepower from the small size engines, hence it also helped to reduce the size of the engine based on the power requirement. As well as it extracts part of the energy loss in waste exhaust gases, thus it is a more efficient method than supercharging.