The engine is an assembly of many essential components and mechanisms, each of which plays a unique role in powering the vehicle. In this article, we’ll go through the engine crankcase in detail, which is one of the most significant components of the engine.

Contents:

What is an Engine Crankcase?

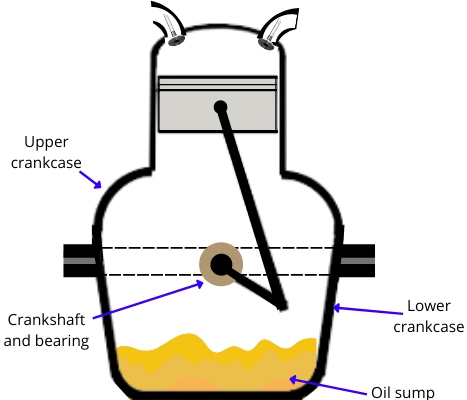

Crankcase is the enclosure or housing made for mounting of the crankshaft. It is one of the main components of the engine that creates an enclosure for the vital engine components like crankshaft, connecting rod, bearings, etc.

The crankcase is mostly formed by the two different halves. The upper half of the crankcase is made by the lower portion of the engine block and the lower half of the crankcase is connected to the upper half to form a crankcase cavity.

The bearing journals of the crankshaft are fitted between the upper and lower crankcase.

The engine crankcase is generally made from the same material as an engine block because both of them are subjected to the same amount of temperature stress.

The lower part of the crankcase also acts as an oil reservoir for storing the engine oil.

The crankcase helps to protect the engine components from dirt and can withstand the crankshaft firmly against the forces coming from the piston.

Crankcase function:

Following are some of the important functions of the engine crankcase:-

1] Enclosure to the vital components:-

The crankcase creates an enclosure for the crankshaft, connecting rod, bearing, etc. It protects the engine components from dirt and shocks.

2] Rigid structure to mount crankshaft:-

The crankcase holds the crankshaft firmly by means of crankshaft bearings and is capable to withstand forces that arise due to the running of connecting rod, crankshaft, etc.

3] Holds the lubricating oil:-

In 4 stroke engines, the lower portion of the crankcase acts as an oil sump. The oil from the oil sump is spread over the different engine components and again it returns to the oil sump of the crankcase.

4] Pressurising chamber in the 2-stroke engine:-

In 2 stroke engine, the crankcase acts as a pressurizing chamber that along with the piston help to compress and feed the intake charge into the cylinder through the auxiliary port.

Thus the crankcase performs a vital role in the running of the two-stroke engines.

5] Helps to cool the oil:-

The lower part of the crankcase is in contact with the running air. Thus this air helps to cool the oil inside the crankcase by convective heat transfer.

Parts of Crankcase:

The crankcase of the Internal combustion engine consists of the following parts:-

1] Upper crankcase:

The lower portion of the engine block serves as the upper crankcase that makes half enclosure for the crankshaft.

2] Lower crankcase:-

The lower crankcase is connected to the upper crankcase by means of bolts or studs. The lower crankcase has a lower half portion for fitting the bearing.

It also works as an oil sump for the engine oil.

3] The crankcase has multiple openings to connect the breathing line, PCV valve, crankcase pressure gauge, oil drain, etc.

Positive crankcase ventilation:

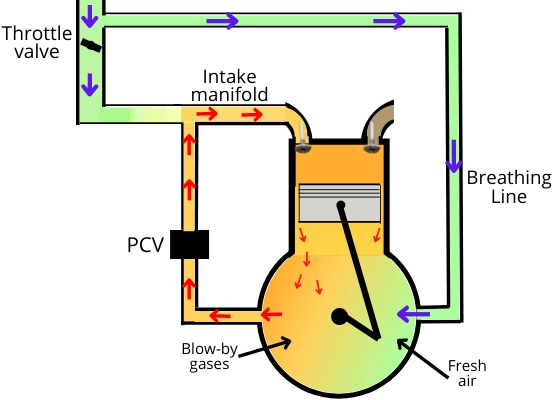

The crankcase ventilation is needed to remove the blow-by gases from the crankcase.

Due to the high pressure inside the combustion chamber, some gases get leaked from the piston rings into the crankcase. These blow-by gases are combustion products that contain impurities.

These impurities get mixed with the lubricating oil and form a sludge in the crankcase. This sludge can corrode the engine components.

Thus the crankcase ventilation system removes the blow-by gases from the crankcase by the use of the vacuum present in the intake manifold and replaces them with fresh air.

The above figure shows the schematic diagram of the positive crankcase ventilation.

As shown in the above figure, one end of the PCV valve is connected to the intake manifold and another end is connected to the crankcase.

The breathing line is used to replace the blow-by gases with fresh air. One end of the breathing line is connected to the crankcase and another end is connected to the fresh air line before the throttle valve.

The PCV valve is the unidirectional valve and it gets opened when the pressure inside a crankcase rises due to the blow-by gases. Thus due to the pressure difference between the intake manifold and the crankcase, the gases inside the crankcase moves towards the intake manifold.

At the same time, the breathing line supplies fresh air to the crankcase.

Crankcase Evacuation:

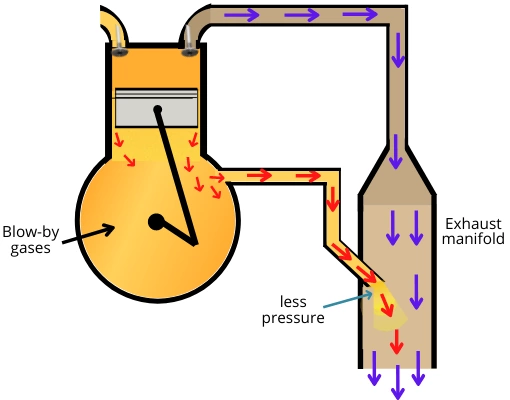

Crankcase evacuation is the process of building a vacuum inside a crankcase to remove all blow-by gases and to increase the power output of the engine.

The blow-by gases increases the pressure inside a crankcase and this pressure rise inside a crankcase opposes the downward motion of the piston during the power stroke. Hence the engine loses some power to oppose the pressure inside the crankcase.

Therefore in some engines, the vacuum is developed inside a crankcase to remove the gases from the crankcase to reduce the pumping losses. Therefore the crankcase evacuation helps to increase the power output of the engine.

The excessive pressure building in the crankcase also leaks the gaskets and piston rings.

To create a vacuum, some cars use a dedicated vacuum pump while some cars take the help of the exhaust flow to develop a vacuum. The general diagram for vacuum generation by use of exhaust flow is shown below

As shown in the figure, the inclined pipe is fitted inside the main header of the exhaust manifold.

The high-velocity exhaust gases lowers the pressure at the entry of the inclined pipe which is inserted into the main header. Hence it helps to draw the gases from the crankcase and creates a vacuum.

Crankcase pressure sensor:

The crankcase pressure sensor is the sensor used to check the pressure of engine oil in the crankcase. The crankcase pressure sensor gives input to the PCM about engine oil pressure.

The sensor tells about the excessive pressure buildup in the crankcase and avoids the leakage of gaskets and seals.

As the pressure in the crankcase exceeds the limit, the PCM shows the error code PO51B.

Crankcase oil filter:

A crankcase oil filter is used to separate the oil contaminants from the crankcase blow-by gases before it enters the intake manifold.

The PCV helps to avoid the excessive building of pressure inside the crankcase by sending the blow-by gases again to the intake manifold.

During this ventilation process, some traces of the engine oil are carried along with the blow-by gases.

Without using the filter, these gases along with the small extent of engine oil will directly enter in the engine. Thus to avoid these, the crankcase oil filter is used.

FAQs:

-

What is the crankcase used for?

The crankcase is used to hold the crankshaft and to protect engine components.

-

What is the difference between an engine block and a crankcase?

The piston is mounted inside the cylinders made into the engine block while the crankshaft is mounted into the crankcase.

-

What is the purpose of crankcase ventilation?

The purpose of crankcase ventilation is to remove the blow-by gases from the crankcase and send it again to the intake manifold.