What is Fin in Heat transfer?

Fin is the extended surface that is used to increase the rate of convective heat transfer. The fins are generally used on the surface where the heat transfer rate without the use of fins is insufficient to cool or heat the body.

As per the formula of convective heat transfer, the rate of heat transfer is directly proportional to the area exposed to the convective medium.

Therefore the fins help to increase the area exposed to the circulating medium. Firstly, The heat is transferred from the body to the fins by means of conduction, then this heat from the fins is transferred away by convection.

Let’s see more in detail.

In this article, we’re going to discuss:

- Properties of fins:

- Types of fins:

- Performance of fins:

- Advantages of fins:

- Disadvantages of fins:

- Application of fins:

Properties of fins:

The material for fins are selected on the basis of the following properties:-

1) High thermal conductivity

2) Light-weight

3) Castability

4) Corrosion-resistant

Types of fins:

Based on the operating condition and area available the fins are classified as,

1) Straight fins: The straight fins are generally arranged normally to the surface of the body and in parallel directions.

Based on the cross-section, the straight fins are further classified as,

A) Rectangular profile straight fin

B) Trapezoidal profile straight fin

C) Concave profile straight fin

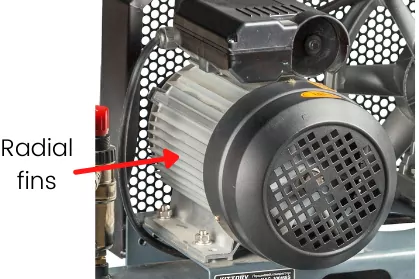

2) Radial fin: Radial fins are fitted on the cylindrical surface as shown in the figure. Based on the cross-section, these fins are also classified as,

A) Rectangular profile

B) Trapezoidal profile

3) Annular fin: The annular fins are of annular shape fixed on the periphery of the cylindrical body.

It is also classified on the basis of cross-section used for fins as follows,

A) Trapezoidal profile annual fin

B) Rectangular profile annual fin

C) Concave profile annular fin

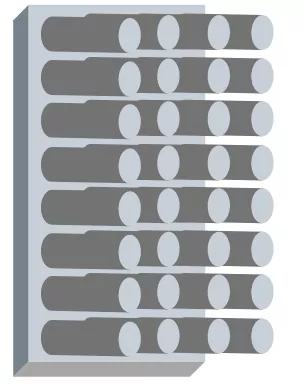

4) Pin fin: The pin fins have a lower cross-section area but in this case, the surface area exposed to the convection is more.

Performance of fins:

The performance of the fins is measured by using the following parameters:

A) Fin effectiveness:- The fin effectiveness shows the relation between the rate of heat transfer by using fins and by without the use of fins.

Mathematically, fin effectiveness is given by,

`E_{\text{Fin}}`=`\frac{Q_{\text{Fin}}}{Q_{\text{Without fin}}}`

B) Fin efficiency:- Fin efficiency gives the relationship between the actual rate of heat transfer and maximum possible heat transfer through fin.

Mathematically, Fin efficiency is written as,

`\eta_{\text{fin}}`=`\frac{Q_{\text{Actual}}}{Q_{\text{Max}}}`

Advantages of fins:

The fins have the following advantages:-

- Increase in the rate of heat transfer

- Easy and cheap way for cooling of equipment

- It is not necessary to increase the convective heat transfer coefficient by using different cooling mediums.

Disadvantages of fins:

- The weight of the body increases due to the fins.

Application of fins:

Based on the purpose of fins, to increase the rate of convective heat transfer, the fins are used in the following applications:-

1) Radiator used in automobile

2) On engine surface in bikes

3) Compressors

4) Codensers of refrigerator or AC

5) On electric transformers

6) On electric motor

7) In other electric and electronic components

FAQ’s

-

What is fin in heat transfer?

Fins are the extended bodies attached to accelerate heat transfer rate by increasing the area exposed to convective heat transfer.

-

What are the types of fins?

There are four types of fins which are Straight fin, Radial fin, Annular fin, and Pin fin.

Good information 👍

The Information was very Helpful!!

Keep sharing