Friends, Are you looking for a Knock sensor? then this article is definitely going to be helpful to you, we have shared a lot of valuable information about knock sensor. We discussed Knocking or Detonation in our other article. Thus today we are going to discuss the Knock sensor which is used to stop knocking in the IC engine.

Knock sensor is the knocking phenomena sensing sensor that helps the engine from getting damaged by the knocking and to improve engine performance. Knocking is the abnormal combustion that happens inside the engine which over a long time badly damages the engine components.

In this article, we’re going to discuss:

- What is a Knock sensor?

- Knock sensor working principle:

- Knock sensor function:

- Construction:

- How does a knock sensor work?

- Advantages:

- Disadvantages:

- Bad knock sensor symptoms:

- Bad knock sensor causes:

What is a Knock sensor?

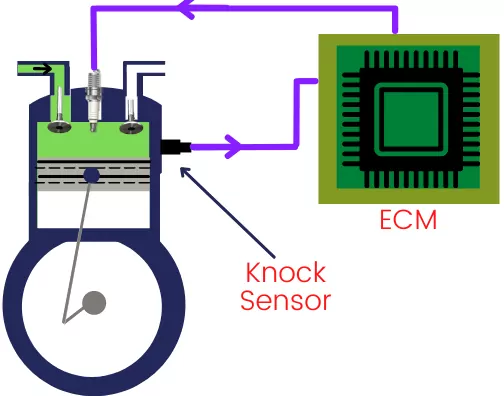

The knock sensor is the device that detects the engine cylinder vibrations due to knocking and sends the electric signal to the ECM (Engine control module).

When the ECM receives an electric signal, the ECM retards the ignition timing or spark timing and stops the occurrence of knocking inside the engine.

The voltage of the electric signal produced by the knock sensor depends on the intensity of the knocking.

Thus the knock sensor helps the Internal combustion engine by sending the knocking signals to ECM, Since the knocking over time has a bad impact on the engine, the high temperature and vibrations produced during knocking damage the engine components.

The knock sensor is screwed onto the engine’s block or at the cylinder head.

Knock sensor working principle:

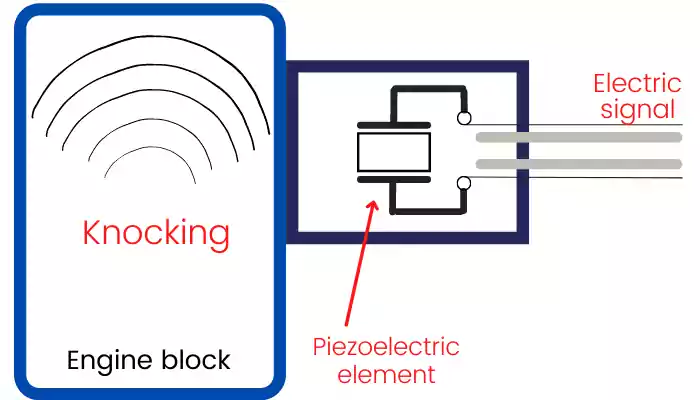

The knock sensor is the piezoelectric type sensor which uses the piezoelectric element that senses the vibrations produced inside the engine due to knocking and sends electric signals to the ECM.

When the ECM receives signals of a certain voltage from the engine, ECM retards the ignition timing. Hence ignition starts closer to the TDC than before which reduces the knocking tendency inside the engine.

By retarding the ignition timing, the knock sensor reduces the peak pressure and temperature inside the engine and resulting in knocking stops.

Knock sensor function:

The purpose of using a knock sensor in engine is as follows:-

- To stop knocking in the engine.

- To reduce the waste of power.

- To improve the fuel economy.

- To increase the torque output.

- To sense the vibration inside the engine.

Construction:

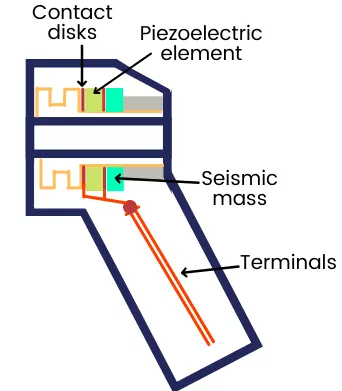

The knock sensor consists of the following key elements:-

Piezoelectric element: The piezoelectric element is the ceramic disc. When the piezoelectric element is subjected to pressure during engine vibration, the accumulation of electric charge occurs in this element.

Contact disks: The contact discs are located on both sides of a piezoelectric element. The contact disks help to conduct the electric charge accumulates in a piezoelectric element to the terminals.

Seismic mass: Due to the inertia of the seismic mass during engine vibration, the pressure on seismic material changes continuously in a rhythmic manner. Hence this change in pressure is sensed by the piezoelectric element that causes the accumulation of electric charge in this element.

How does a knock sensor work?

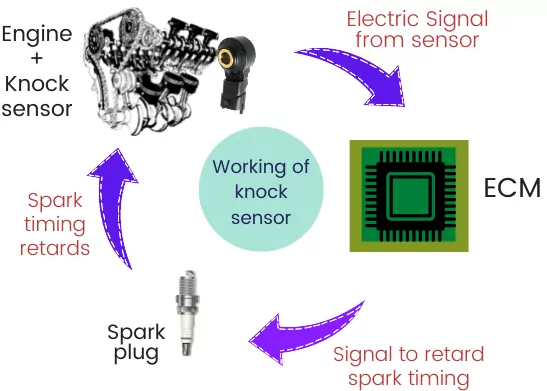

The knock sensor is screwed onto the engine block. When the knocking starts in the engine, high pressure and vibrations are created inside the engine. Due to high vibrations, the electric charge starts accumulating inside the piezoelectric element.

There are contact discs are located on both sides of a piezoelectric element, hence the electric charge produced inside the element flows from the contact discs to the terminals which are further connected to the ECM (Engine control module).

The magnitude of electric charge voltage depends on the intensity of vibrations produced during the knocking.

When the ECM receives the electric signal from the knock sensor, ECM retards the ignition timing until the knocking stops. Hence due to this, the ignition occurs closer to TDC than before, and in such a way, the Knocking stops inside the engine.

After the knocking stops, the ECM sets the ignition timing as before.

Advantages:

The advantages of the knock sensor are as follows:-

- Reduces the tendency of knocking

- Improves the horsepower

- Improve fuel economy

- Reduces the engine vibrations caused by knocking

- Secures engine components from getting damaged due to knocking

- Reduces the emissions of unburnt gases

- Improves the engine performance

Disadvantages:

The disadvantages of the knock sensor are as follows:-

- Lower accuracy due to the noise generation during knocking.

- Requires timely maintenance.

- High cost.

- More complexity.

- Falis over time hence timely replacement is required which is costly.

Bad knock sensor symptoms:

The bad knock sensor symptoms are as follows:-

- An audible knocking sound is produced.

- An engine warning light will get ON.

- ECM will store the corresponding trouble code.

- Engine power lack.

- More fuel consumption and less acceleration.

Bad knock sensor causes:

The knock sensor fails due to the following reasons:-

- Breakage of sensor wiring.

- Incorrect installation

- Damaged due to drop

- Hammering during loosening

FAQs:

-

What is the purpose of a knock sensor?

The main purpose of the knock sensor is to stop the knocking in the engine.

-

What does knock sensor do to the engine?

The knock sensor senses the vibrations produced inside the engine due to knocking and sends an electric signal to the ECM. Then ECM retards the ignition timing to reduce the knocking in the engine.

-

is a knock sensor important?

Yes, the Knock sensor plays the main role in the IC engine to reduce the knocking in the engine. Hence it improves the engine performance.

-

What causes a knock sensor to go bad?

The knock sensor goes bad mostly due to the breaking of the knock sensor wire and due to improper installation.

-

What are the signs of bad knock sensor?

The signs of a bad knock sensor are an audible knocking sound produced from the engine, Check engine light will get ON as well as engine fuel consumption increases, etc.

-

Where is knock sensor located?

The knock sensor is located at an engine’s block or at a cylinder head.

Read also:

Media Credits:

- Knock sensor image used in Featured Image by Bosch Motorsport