Leaf spring is one of the suspension systems which consists of a number of curved shape plates (known as leafs) that are held with each other with the help of a central bolt.

As per the shape and number of plates used, there are different types of Leaf springs. Here we are discussing the semi-elliptical leaf spring.

In this article, we’re going to discuss:

- What is Semi elliptical leaf spring?

1.1. Construction: - Nipping of leaf spring:

- Advantages of Semi elliptical leaf spring:

- Applications of Semi elliptical leaf spring:

What is Semi elliptical leaf spring?

Semi elliptical leaf spring is one of the types of leaf spring which is widely used in heavy vehicles for rear suspension.

As per the name, it consists of a number of flat plates of rectangular cross-section bend in a semi-elliptical shape.

Construction:

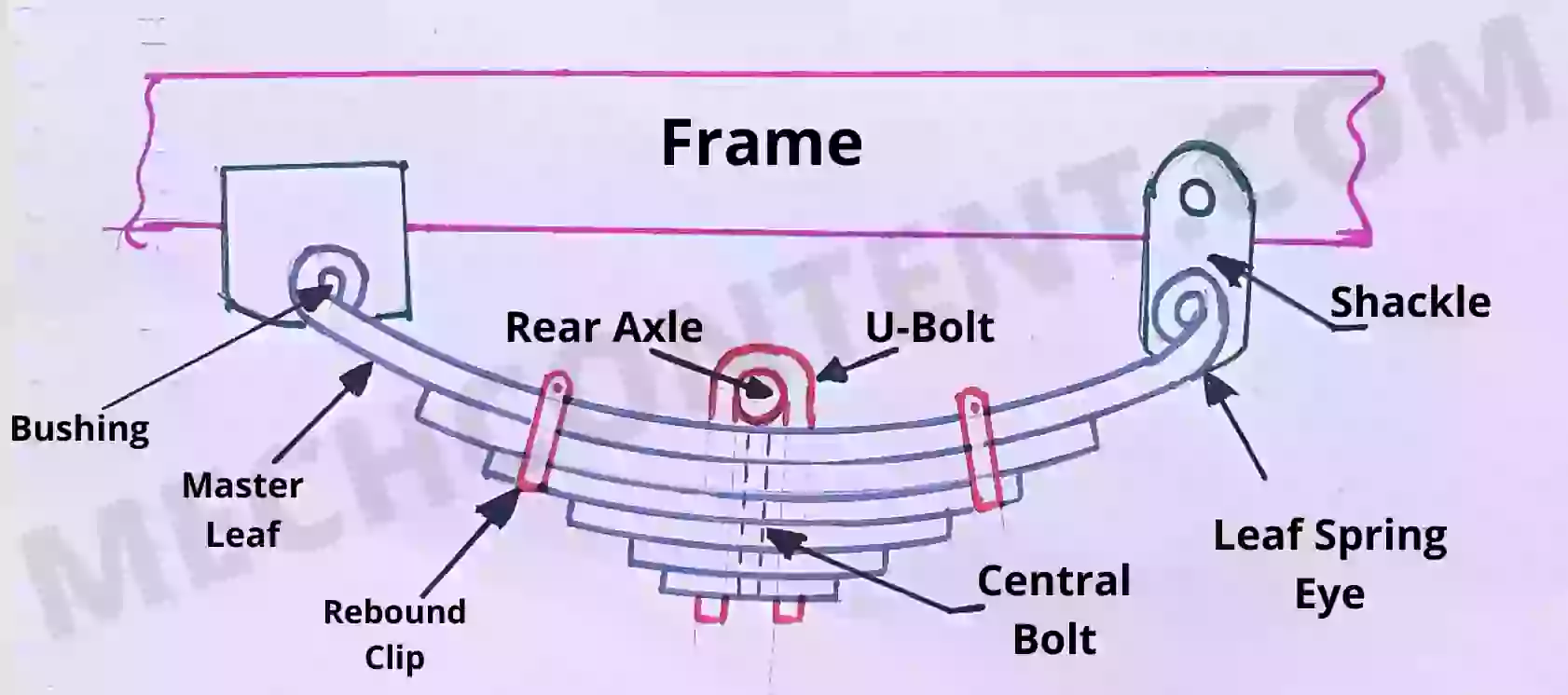

The leaf’s used in this spring has different lengths. All the leafs are arranged together with decreasing order of length. It means, the longest leaf is on top and short leaf is at bottom.

The upper leaf is known as the master leaf and other leafs under master leaf are known as graduated leafs. All the leafs and rear axle are hold together with the help of U-bolt.

One end (Left eye) of the master leaf is fixed to the frame, and another end (right eye) of the Master leaf is connected to the shackle. The shackle can rotate to compensate the deflection of the leaf spring.

When leaf spring moves upward due to bumping, the shackle rotates about the fulcrum to compensate for horizontal deflection.

The rebound clips are used, which holds the master leaf and graduated leafs together. Hence, the stresses are distributed over the complete length of each leaf.

In leaf spring, stresses due to bearing load are distributes over the complete length of each leaf. Hence, it has the ability to withstand the higher working load.

Nipping of leaf spring:

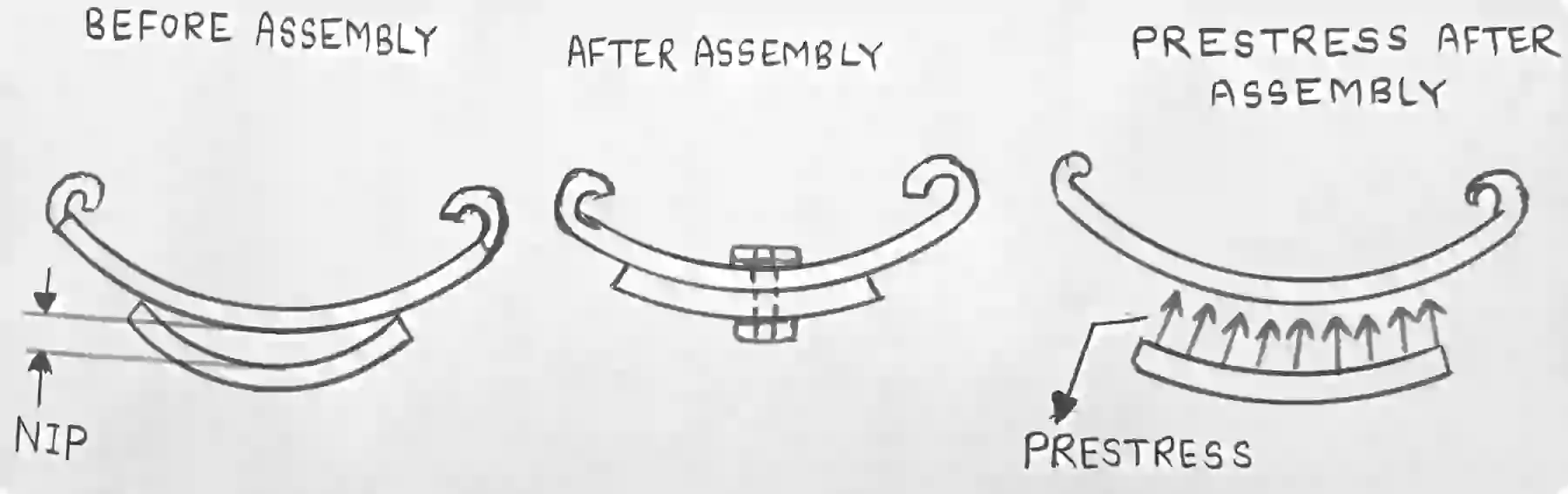

Nipping is method to apply pre-stress on graduated leafs for sharing of load equally.

Generally, the maximum load comes on the Master leaf, Hence Due to nipping, stress on the main leaf is reduced by sharing with graduated leafs.

This method increases the efficiency of the leaf Spring, that increases the life of the leaf spring.

How nipping is done?

As shown in the above figure, nip is the gap between the adjacent leaf spring when they are not assembled. The nip is generated by reducing the radius of curvature of the next adjacent leafs.

In the same manner, radius of curvature for every next leaf is reduced for provision of nip.

Then by using U-Bolt all the leafs are tight together to remove the gap between the leafs.

Due to this, the pre-stress is generated in each leaf, which tries to regain its original shape. Thus pushes its upper leaf in upward direction. This method is known as nipping of leaf spring.

Nipping helps to distribute load on master leaf to each graduated leaf.

Advantages of Semi elliptical leaf spring:

It has the following advantages:

- It can work for heavy load.

- It absorbs vibration due to irregular road surfaces and provides the comfort ride.

- It keeps the vehicle tires in contact with the road on the irregular road surface.

Applications of Semi elliptical leaf spring:

Semi elliptical leaf springs are mainly used in heavy vehicles such as:

- Truck

- Buses

- Train