What is Bell Coleman Cycle?

Bell Coleman cycle (Reverse brayton cycle) is used for air refrigeration, which consists of the two isentropic processes and two constant pressure processes. In air refrigeration, its purpose is to absorb heat from the low-temperature cabin and reject it to the high-temperature atmosphere.

This cycle is used for the both heating and cooling purpose and uses air as a refrigerant (working fluid).

In this article:

Construction:

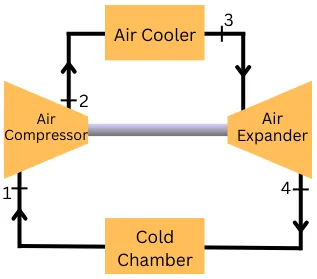

The below figure shows the basic block diagram for this cycle.

This refrigeration cycle consists of the following parts:

1) Compressor: It is used to compress the air at high pressure that comes from the cold chamber.

2) Cooler: It is a cooling device that is used to remove the heat from compressed air with the help of a cooling medium.

3) Air expander: It is an expansion device that converts the high-pressure air into low-pressure air. It causes considerable drop in air temperature. The work produced during expansion is used to drive the compressor.

4) Cold chamber: It is space which has to maintain cooled. When cold air enters the cold chamber, it takes the heat from the cold chamber and lowers the temperature of the chamber.

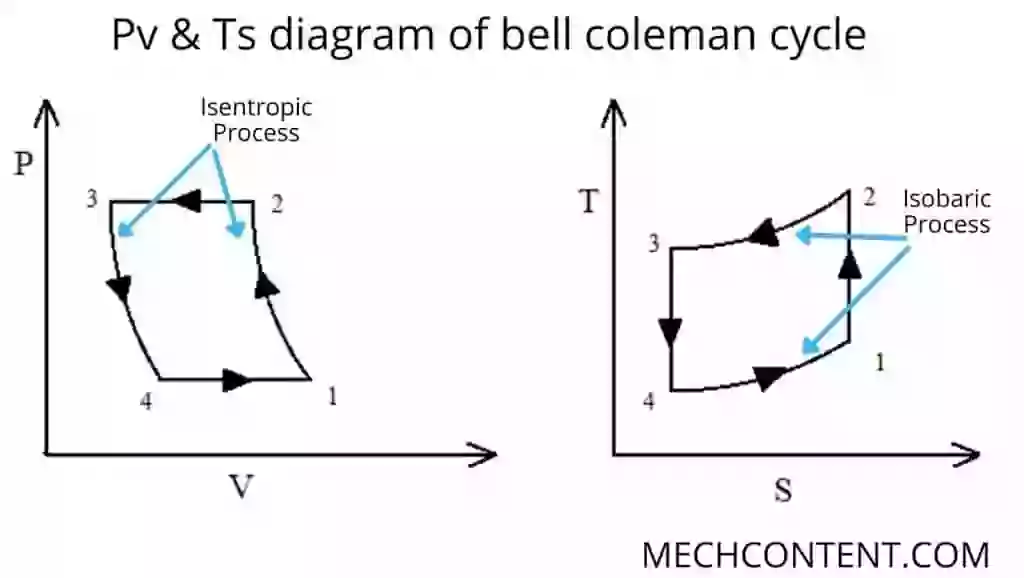

Bell coleman cycle PV and TS diagram:

This cycle consists of two isentropic processes and two isobaric (constant pressure) processes.

The four Processes in the Bell Coleman cycle are as follows:-

- Process 1-2:- Isentropic compression (from P1 to P2).

- Process 2-3:- Constant pressure heat rejection.

- Process 3-4:- Isentropic expansion (from P3 to P4).

- Process 4-1:- Constant pressure heat addition process.

Working :

The air refrigeration system based on this cycle works in following steps:

Compression:

The compressor takes the air from the cold chamber and compresses them to high pressure.

Heat rejection:

The high pressure and high-temperature air from the compressor flow to the cooler. In a cooler, heat removes from the air with the help of a cooling medium, which may be water.

Expansion:

After cooler, low temperature and high-pressure air passes through the expander. The expander expands air to low pressure & produces work that is used for the driven compressor.

Cooling:

The low pressure & low-temperature air from the expander enters the cold chamber, where air absorbs the heat from the cold chamber (which to be cooled) and provides a cooling effect.

After absorbing heat from the cold chamber, air again flows to the compressor. In such a way, the cycle continues again & again.

Advantages:

Following are some of the advantages of using this cycle:

- Simple in construction.

- Air is used as refrigerant, which is cheaply available and also non-toxic.

- No harmful, if any, leakage.

- Low maintenance cost.

Disadvantages:

Following are the disadvantages of this cycle:

- The system is bulkier, hence weight per ton of refrigeration is higher.

- High operation cost.

- Less coefficient of performance (COP) as compared to other systems.

Read also: