What is a Vapour compression refrigeration system (VCRS)?

Vapour compression refrigeration system is one of the types of refrigeration system, Extensively used in refrigeration, Air conditioning for industrial, domestic, and automobile uses.

This system uses the compressor to compress the refrigerant.

The different kinds of Refrigerants used in VCR like NH3, R-134a, R-12, R-22, etc.

Contents:

Construction:

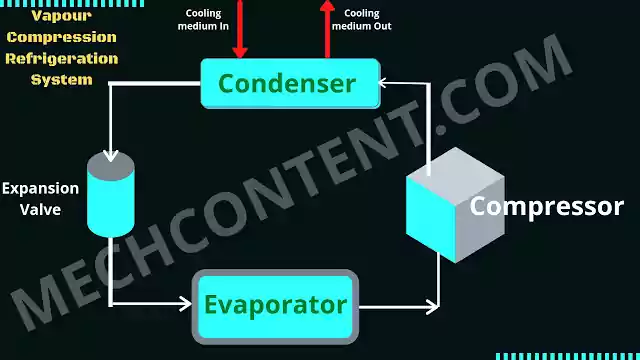

The key components of a vapour compression refrigeration system are Compressor, Condenser, Expansion Valve, and Evaporator.

This is the basic diagram of the Vapour compression refrigeration system.

Compressor:- It is used to compress the refrigerant to high pressure. So it converts the low-pressure vapour refrigerant to the high-pressure hot vapour refrigerant.

Condenser:- It is used to remove the heat of highly compressed vapour refrigerant with the help of cooling medium (Air or water). So it converts the high-pressure hot vapour refrigerant to high-pressure cooled liquid refrigerant.

Expansion valve:- This valve is used in a system to convert high-pressure liquid refrigerant to low-pressure and low-temperature.

Evaporator:- It is used to absorb heat from the enclosed space (Space where we want to create a cooling effect) with the help of refrigerant. So after passing through the evaporator, the refrigerant gets converted into low-pressure hot vapours.

Working of Vapour compression refrigeration system:

When the refrigerant comes inside the compressor, the compressor compresses the refrigerant and increases its pressure & temperature.

After coming from the compressor, hot high-pressure vapour refrigerant enters into the condenser. In a condenser, refrigerant gets cooled by a cooling medium. Hence vapour refrigerant gets converted into a liquid state.

After the condenser, the high-pressure liquid refrigerant enters into the expansion valve. By expanding the refrigerant, the expansion valve reduces the pressure and temperature of the refrigerant. So the liquid refrigerant converts into vapour state.

After the expansion valve, low-temperature vapour refrigerant enters into the evaporator. In the evaporator, the refrigerant absorbs the heat from the outer enclosed space. So due to absorbing the heat, refrigerant temperature increases and gets converts into a gaseous state.

After the evaporator, the low pressure vapour refrigerant again enters into the compressor. In such a way, the whole cycle continuously repeats till a preset temperature is not get achieved in an enclosed space.

Advantages of the VCR system:

The advantages of the Vapour compression refrigeration system are as follows:-

- VCR system has a High COP (Coefficient of performance)

- It has less running cost.

Disadvantages of the VCR system:

The disadvantages of the Vapour compression refrigeration system are as follows:-

- The initial cost of a VCR system is high.

- Need prevention of refrigerant leakage.

- The refrigerant required is costlier.

Applications:

The applications of the Vapour compression refrigeration system are as follows:-

- Domestic Refrigerator.

- Industrial Refrigerator.

- Domestic Air Conditioning.

FAQs:

-

What are the 4 stages of vapour compression refrigeration cycle?

The four stages of the VCR cycle are Compression, Condensation, Expansion, and Evaporation.

-

Where is the Vapour compression refrigeration system used?

A VCR system is used in Industrial Refrigerators, Domestic Refrigerators, and Air conditioners.

-

What are the limitations of the Vapour compression refrigeration system?

VCR system has limitations that, Its capital cost is high as well as it requires costly refrigerant.

You may also like this: