What is Chemical Machining (CHM)?

Chemical machining is a machining process in which material removal carried out with the help of chemicals. These chemicals react with work-piece material and dissolves it.

It is one of the non conventional machining process.

Continue reading to know about its working process, construction, advantages, etc.

Contents:

Construction:

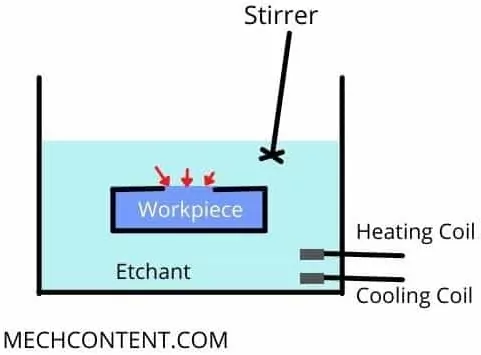

The below figure gives the basis idea of chemical machining.

Chemical Machining setup consists of the following components.

1) Chemical :- The chemical used in this process is also called as etchant. This chemical is responsible for the removal of the material from the work-piece.

It chemically reacts with the desired portion of work-piece material & dissolve it.

The types of etchants used in machining depends on the material of work-piece.

2) Cooling & Heating Coil :- The Cooling & Heating coil is used to maintain desired temperature of the chemical or etchant during the process.

3) Stirrer :- The stirrer helps in the mixing of the chemical or etchant.

Chemical Machining Working:

The chemical machining is done in following processes or steps :-

1) Cleaning :- In this step, the work-piece is cleaned using solvent to removes the dust, oil contaminants from the work-piece. It is necessary to clean, as the masking will not be done properly due to dust or oil contaminants.

2) Masking :- Masking is the process of applying the maskant or cover on the cleaned work-piece surface. This maskant or cover does not react with chemical or etchant.

It protects the covered portion of work-piece surface from being dissolved.

3) Scribing :- In this process, the maskant is removed from the portions of work-piece surfaces which has to be machined. It is done before the immersing work-piece in the chemical or etchant.

4) Etching :- In this process, the workpiece is immersed in the chemical or etchant. The chemical reacts with the work-piece surface where maskant is not present & dissolves this portion of the work-piece.

5) De-masking :- After the etching process, the remaining applied maskant is removed.

Therefore, in such way, chemical machining works.

Advantages of Chemical Machining:

- It produces high precision metal parts.

- It can machine any shape & size.

- Machining of work-piece from all sides at the same time.

- Less skilled labors can handle process

- High surface finish

- High machining accuracy

Disadvantages of Chemical Machining:

- Chemical solution used in this process is dangerous for human health.

- It is a slow process.

Applications of Chemical Machining:

- In drilling different sizes holes on plates.

- In machining of various automobiles parts.

Read also: