Are you looking for supercharging information, then here we wrote a detailed article about Supercharging. As we already discussed about the engine, device which consumed the air-fuel mixture and produces power. So practically in the engine, due to some reasons, less power obtains at the output such as due to the improper combustion, less speed, etc.

Hence to increase the power output of the engine, One option is increasing engine speed, but the problem with increasing the speed is that it also increases the many issues like stresses on the engine components, more fuel consumption, wearing of parts, So overall it reduces the engine life.

Hence to increase the power output of the engine, researchers studied for proper combustion to increase the power output and then invented a great device which is a supercharger. Now you may ask, “Supercharger, but how does this device increase engine power output?”. So, friends Supercharger is helps in proper combustion which results in more power output. So today we are going to learn a lot about that.

Supercharging is the process of compressing the inlet air before it enters into the engine, increases the air density which helps in proper combustion and increases the power output of the engine.

In this article, we’re going to discuss:

- What is supercharging in ic engine?

- Supercharger working principle:

- Purpose of supercharging in ic engine:

- Supercharging Parts and Construction:

- How do superchargers work?

- Types of supercharging in ic engine:

- Roots vs twin screw vs centrifugal:

- Supercharging in si engine:

- Supercharging in ci engine:

- Advantages and disadvantages of supercharging in ic engine:

What is supercharging in ic engine?

Supercharging is the process of increasing the Naturally aspirated engine (Normal engine that doesn’t use an external device to force the intake air) power by increasing the intake air density. So, Supercharging is the process of compressing the intake air while the device used for the supercharging is known as a Supercharger.

Supercharging provides high compressed air with the help of a compressor. Compressed air within the same swept volume contains more oxygen which helps for proper burning of fuel and results in more power output.

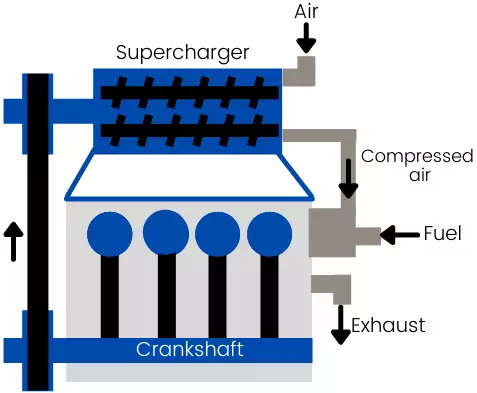

Supercharging is the forced induction system. The supercharger used in this process is generally a kind of compressor driven by the engine crankshaft power with the help of belt drive or chain drive.

Supercharger working principle:

The supercharger works on the following principle:-

The supercharger uses the engine power output (Power available at the crankshaft) to compress the intake air which further helps in proper combustion inside the combustion chamber. In such a way, the supercharger gives more power output and increases mechanical efficiency.

Purpose of supercharging in ic engine:

The purpose of the supercharging in internal combustion engine is as follows:-

- To provide the compressed (High density) air to engine.

- To increase volumetric and mechanical efficiency of the engine.

- To increase the power output and Torque of engine.

- Reduce the fuel consumtion.

- Reduce the detonation problem in CI engines.

Supercharging Parts and Construction:

Parts:-

The supercharger is consists of the following key components:-

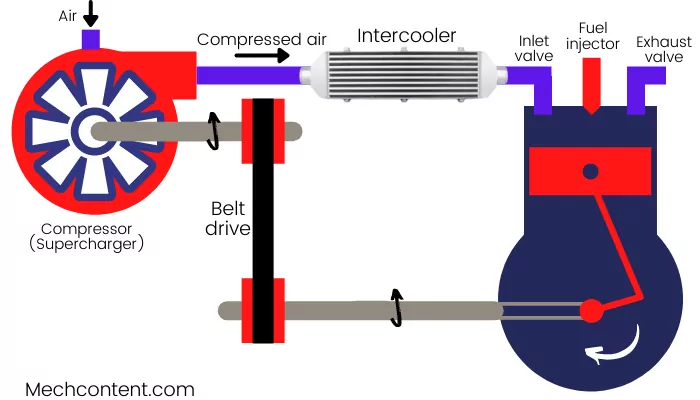

1] Compressor (Supercharger): The compressor which is worked as a supercharger runs on the power received from the engine crankshaft with the help of a belt drive. There are 3 types of compressors (Superchargers) most commonly used in supercharging.

The compressor helps to supply the compressed air to the engine. The output of the compressor is connected to the intercooler where the air is passed to remove the heat from the air. The below figure shows the centrifugal-type compressor.

2] Filter: The filter is located before the intake of the compressor to take inside dirt-free air from the atmosphere. The filter is installed at the inlet way of a compressor.

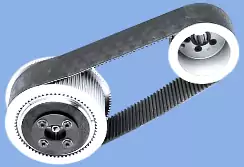

3] Belt drive system: As we know, the compressor runs on the engine power, hence the belt drive helps to transmit power from engine crankshaft to compressor.

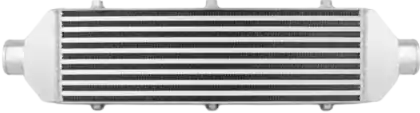

4] Intercooler: The intercooler is located after the output of the compressor or supercharger which works as a heat exchanger to remove the heat from the hot compressed air. The water or air is used as a cooling medium in the intercooler.

The intercooler also helps in increasing the density of the air that increases the volumetric efficiency of the engine.

Construction:-

1] The engine crankshaft is connected to the compressor shaft with the help of a belt drive or chain drive.

2] The supercharger/compressor output is connected to the intercooler to cool the high temperature and pressure air and then the output of the intercooler is connected to the engine intake manifold through which it supplies the high-density air to the engine.

3] The filter is installed on the input of the compressor to take dirt-free air from the atmosphere.

How do superchargers work?

The supercharging process works in the following way (Take reference of above Figure A):-

During the suction stroke, the air entered in the engine, and then air is compressed during the compression stroke.

At the end of the compression stroke, the fuel injector sprays the fuel in hot compressed air, the combustion takes place, and the power is generated by the engine.

The power generated by the engine is available at the engine crankshaft. So now, The belt drive transmits the power from the engine crankshaft to the compressor shaft.

And in such a way compressor runs and supplies the compressed air to the intercooler, where heat is removed from the air. After the intercooler, the finally air goes to the engine.

So in brief, When the engine starts, the power continuously transmits from the engine crankshaft to the compressor. The compressor receives the power from the engine and performs suction of air from the atmosphere then compresses it and supplies it through the intercooler to the engine.

In such a manner, the cycle continues.

Types of supercharging in ic engine:

The 3 types of superchargers are as follows:-

- Centrifugal

- Root

- Twin-screw

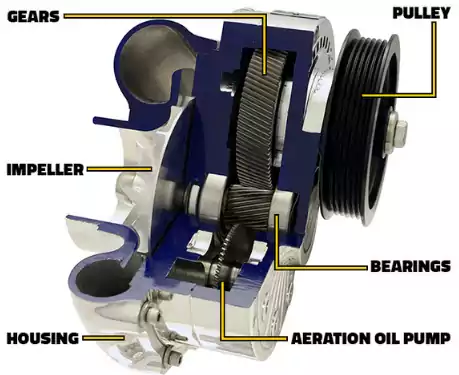

1] Centrifugal supercharger:-

The centrifugal supercharger uses centrifugal force to compress the air to high pressure. This type of supercharger run directly by the power transmission from the engine crankshaft or motor is used to run it. It sucks the air axially from the eye and compresses and delivers it radially with the help of an impeller.

It has the gear drive to run the impeller at a higher speed and increase the pressure. The centrifugal supercharger is simple and more efficient. This supercharger is installed at the front of the vehicle and filter is installed before it.

Credit: Rotrex

Credit: Procharger

2] Root type supercharger:-

The root type supercharger is the positive displacement supercharger which has three helical lobes onto the two rotors. This type of supercharger fastly spool up (Pressure and speed) and generates more power.

This type of supercharger is located above the engine, where it takes the air from the top side and pushes it to the intake manifold from the bottom.

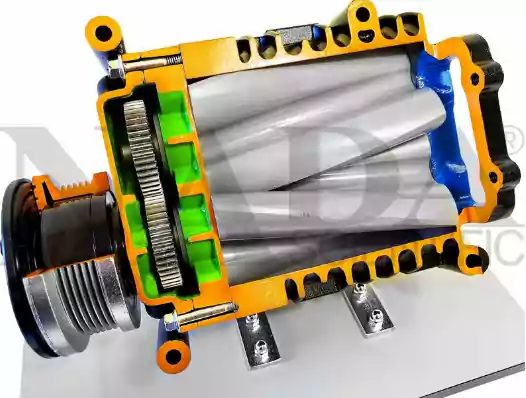

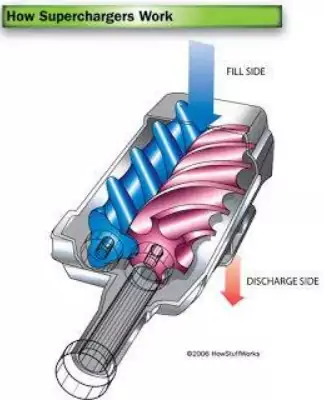

2] Twin-screw supercharger:-

The twin-screw type supercharger as its name suggests it consists of two rotors that look like a screw which are the male rotor and female rotor. It is complex in construction.

It is similar to the root type supercharger but the rotors has a different design. This type of supercharger spull up quickly and gives the higher torque. It is also the positive displacement pump.

Roots vs twin screw vs centrifugal:

| Sr. No. | Centrifugal | Root | Twin-screw |

|---|---|---|---|

| 1] | This is a Non-positive displacement supercharger. | This is a positive displacement supercharger. | This is a positive displacement supercharger. |

| 2] | This supercharger uses the impeller for compressing the air. | This supercharger uses the helical shape lobes on the rotors to compress the air. | This supercharger has two rotors that look like screws which are male and female rotor that compresses the air. |

| 3] | This type of supercharger is located at the front of the vehicle. | This type of supercharger is located at the top of the engine. | This type of supercharger is located at the top of the engine. |

| 4] | This type of supercharger takes air axially from the eye and compresses and discharges it radially. | This type of supercharger takes the air from the top and pushes it from the bottom side. | This type of supercharger takes the air from one end and pushes it from the central output. |

| 5] | This type of supercharger needs an oil supply for lubrication. | Most of this type of supercharger has self lubrication facility. | Most of this type of supercharger has self-lubrication facility. |

| 6] | It generates comparatively less heat than the root type. | It generates heat inside at the high boost level. | It only generates the heat at the output due to compressing air to high pressure. |

| 7] | Less costly | Costly | Less costly |

Supercharging in si engine:

The use of supercharging in the SI engines (Spark ignition) with the lean mixture, increases the intake pressure and temperature causes less ignition delay results in the problem of Knocking or Detonation.

Hence to use supercharging without Knocking in SI engines, the rich mixture is used which increases the ignition lag but with that, it also increases the fuel consumption.

As compared with the Naturally aspirated engine (Normal engine without supercharging), more bottom-end horsepower is obtained using the supercharging in si engines.

Hence, due to the more fuel consumption, In Si engines, supercharging is used where more power output is necessary. Examples:- Aircraft, Racing cars, etc.

Supercharging in ci engine:

Supercharging in the CI engine supplies the high-density compressed air, thus proper combustion takes place as well as gives a better power output. Because of the high pressure and temperature at the intake, the ignition lag decreases which results in reducing problems of Knocking or Detonation.

The supercharged CI engines have lower fuel consumption because of the use of compressed air. The supercharging in the ci engine increases the mechanical efficiency.

Advantages and disadvantages of supercharging in ic engine:

Advantages in case of CI engine:

- Proper combustion hence less emission of carbon monoxide.

- Reduces the fuel consumption

- Compression ratio increses hence Power increase to 1.5 to 2 times.

- Improves the power per weight of engine

- Reduces the knocking or detonation.

- Provides the more torque.

- Increase mechanical efficiency.

- Reduces the ignition lag.

- Better power starts obtaining from the start of engine.

- Less cost method.

- Reduces the exhaust smoke

- Low quality fuel can be used.

- Increase volumetric efficiency.

Disadvantages in case of CI engine:

- Increses the mechanical load on the engine.

- Requirres the engine power to run supercharger.

- Increases the thermal load on engine parts.

- Increases parts wearing.

Advantages in case of SI engine:

- Better power obtained at Bottom-end

- Increses the volumetric efficiency

- No lag

- Less costly

- Better mechanical efficiency.

Disadvantages in case of SI engine:

- More fuel consumption

- Increases loads on the engine.

FAQs:

-

What is the function of supercharging?

The function of supercharging is to maximize the engine’s power output as well as mechanical efficiency.

-

What are the types of superchargers?

There are three types of superchargers are Root, twin-screw and centrifugal.

-

What are the limitations of supercharging?

Supercharging has two main limitations: it takes an engine power to run, and it puts thermal stress on the engine.

Last words:

Supercharging is the forced induction system that supplies compressed air to the engine to increase its power output. The supercharger takes the power from the engine to run but it is an effective method that produces higher power output as compared to a naturally aspirated engine.

So friends if you found this article helpful for you then share it. If have any queries about the Supercharging then put them at below comment box, we will respond to you there.

Read also: