Single plate clutch is a type of friction type Automobile clutch, a Single clutch plate (also known as friction plate) is used. The friction plate has a friction lining on both sides.

When the pressure plate applies force to the friction plate, this friction lining on the friction plate helps to hold the flywheel and pressure plate and rotates all three parts as a single unit.

Hence in such a way, power transmits from the flywheel to the gearbox.

Let’s see in detail about the single plate clutch.

Contents:

What is a Single plate clutch?

A Single plate clutch is a friction-type clutch that consists of a single friction plate (Clutch plate). This friction plate is located between the flywheel and the pressure plate.

This friction plate has a friction lining on both sides. In the running position of the vehicle means when the clutch is engaged, the pressure plate presses the friction plate on the flywheel, Therefore due to friction between them power transmits from the rotating flywheel to the pressure plate.

Single plate clutch diagram:

Construction of Single plate clutch:

1) Single plate clutch consists of main three parts are friction plate, pressure plate, flywheel. And other parts are clutch pedal, clutch spring, and bearings.

2) The flywheel is a connected engine shaft & the pressure plate is mounted on the clutch shaft which is connected to the flywheel with the help of a bolt & spring.

3) Clutch shaft has a splines hence friction plate freely moves on the clutch shaft.

4) Spring is used to press the pressure plate against friction plate to keep the clutch in an engaged position.

5] The clutch pedal is connected to the pressure plate with the help of linkages.

Working of Single plate clutch:

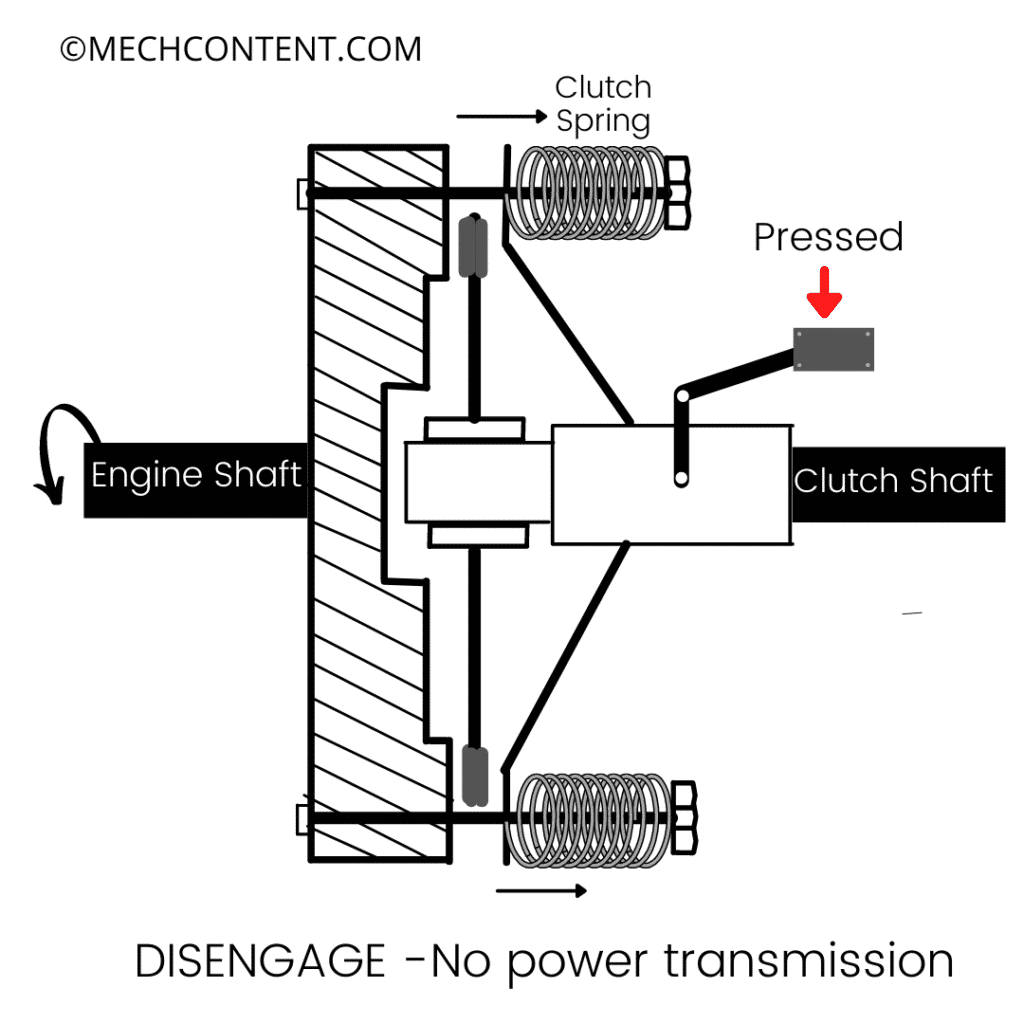

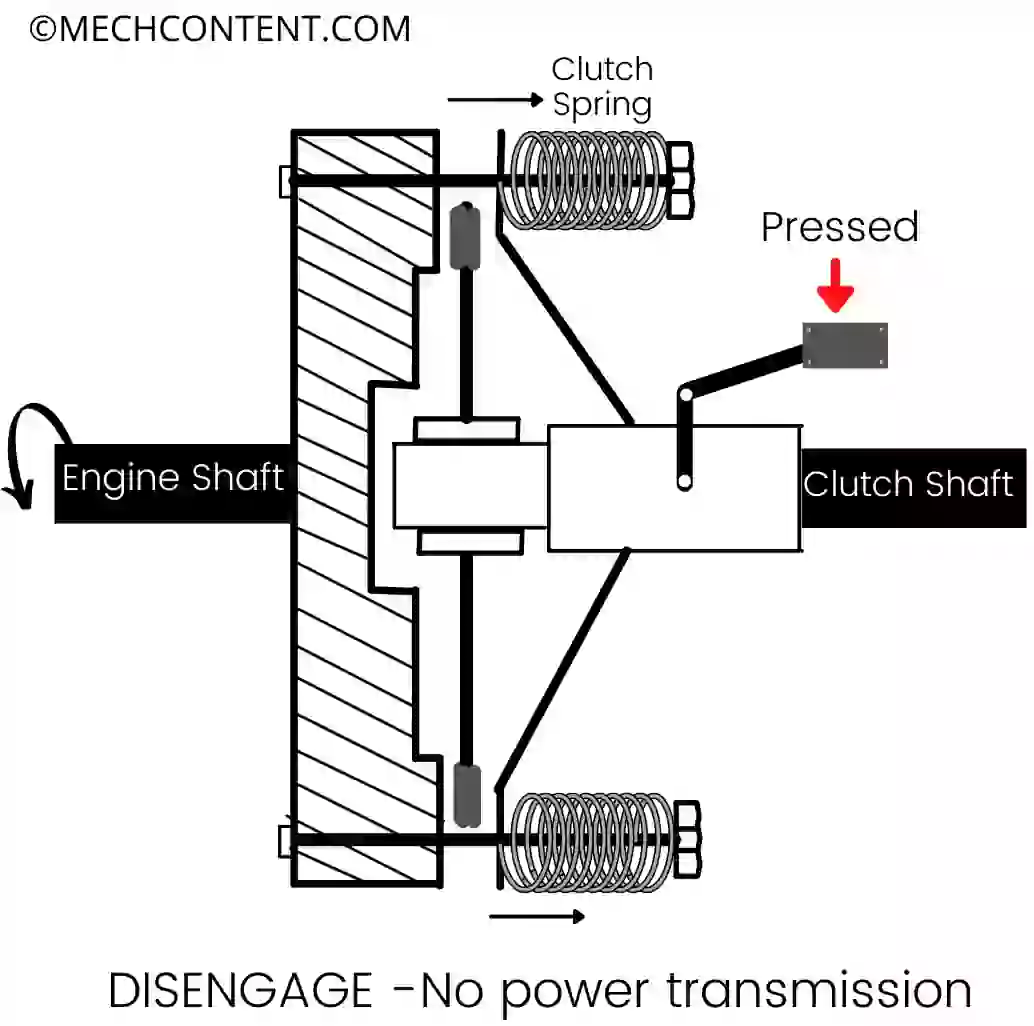

Disengagement:-

1) In an engaged position of the clutch means when a vehicle is running, the pressure plate is pressing the friction plate against the flywheel hence power continuously transmits from the flywheel to the clutch shaft.

2) When the clutch pedal is pressed by the driver, the pressure plate moves towards the right side against the compression of the spring.

3) When the pressure plate moves towards the right side, the force on the friction plate is removed hence friction plate is released therefore clutch is Disengages.

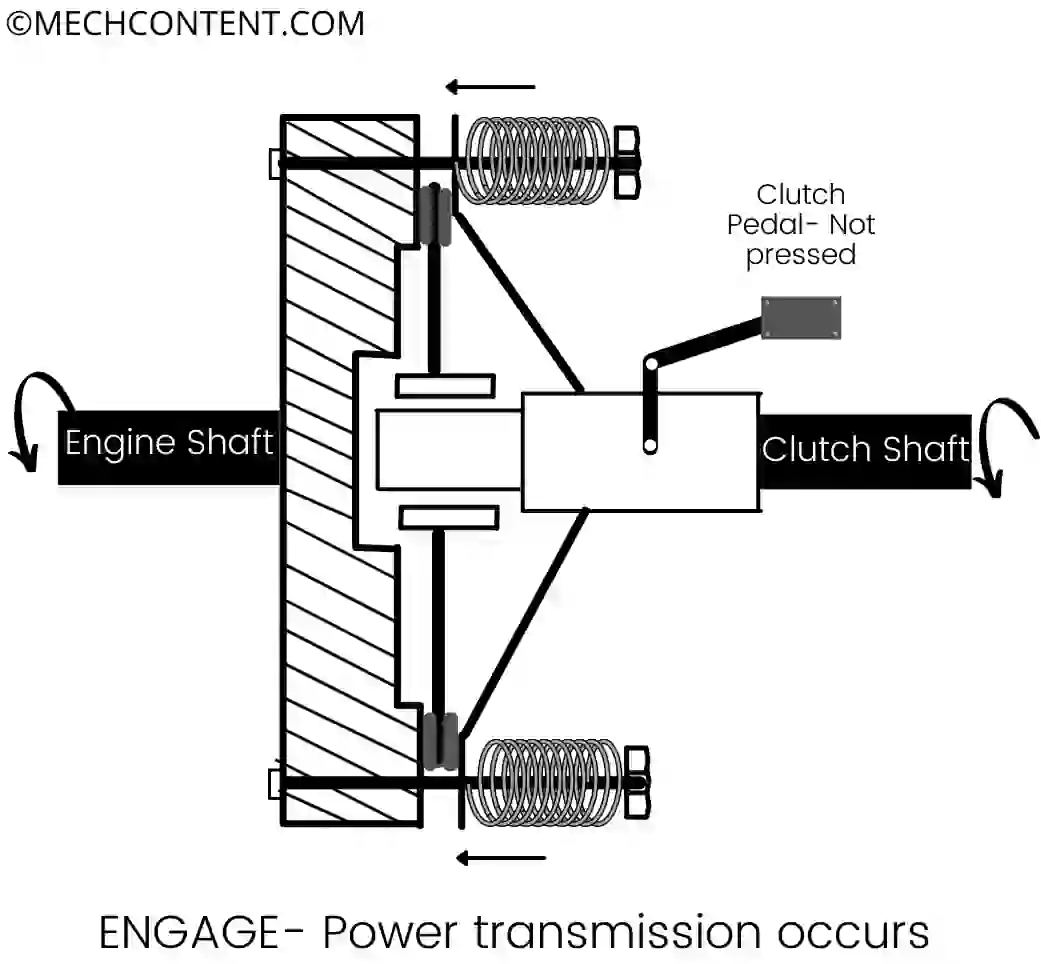

Engagement:-

1) When the clutch pedal is released by the driver, the pressure plate moves towards the left side due to the expansion of the compressed spring, hence the clutch Engages.

2) In a running condition of the vehicle, power continuously transmits from the flywheel to the clutch shaft because the clutch pedal is depressed hence clutch is engaged condition.

3) When the driver shifts gear or slows down the vehicle then the clutch is in disengaged condition.

Single plate clutch formula:

Maximum torque transmitted by single plate clutch for uniform pressure:-

`T=\frac{2}{3}\times \mu \times W [ \frac{ ( R_{1}^{3}-R_{2}^{3} )}{ ( R_{1}^{2}-R_{2}^{2} )} ]`

W = Axial thrust on the plates

R1 = Outer radius of friction surface.

R2 = Inner surface of the friction surface

μ = Coefficient of friction

Maximum torque transmitted by single plate clutch by uniform wear theory:-

`T=\frac{1}{2}\times \mu \times W(R_{1}+R_{2})`

Applications:

The applications of single plate clutch founds in the following vehicles:-

- Trucks

- Buses

- Cars

Advantages:

The single plate clutch has the following advantages:-

- It gives a faster response.

- Easy to change gears using this type of clutch

- Less power loss

- Smooth operation

Disadvantages:

The single plate clutch has the following disadvantages:-

- It requires wider radial space.

- High maintenance required

- Less power transmission capacity

- The rate of wear and tear is quite high.

FAQs:

-

Why single plate clutch is used in heavy vehicle?

A single plate clutch gives faster response than a multi plate clutch and it requires wider radial space. Hence as in heavy vehicles has wide space is available hence generally Single plate clutch is used to give a faster response.

-

What is disadvantage of single plate clutch

A single plate clutch has the disadvantage that It requires wider radial space.

Read also: