What is Electromagnetic braking system?

An electromagnetic Braking system is a system that is used to slow down or stop the rotation of the machine shaft with the help of an Electromagnet.

The electromagnetic braking system operates through electric actuation but produces braking action mechanically.

In this article, we’re going to discuss:

- Working principle:-

- Components of electromagnetic braking system:-

- Working:-

- Applications:-

- Electromagnetic braking system advantages and disadvantages

Working principle:-

The electromagnetic braking system works on the electromagnet field produced by the electromagnet.

What is Electromagnet?

When current passes through the coiled wire, the coil generates a magnetic field around it. It is known as an electromagnet.

In an electromagnetic braking system, the electromagnetic field produced by the electromagnet is used to stop the rotation of the output shaft.

Components of electromagnetic braking system:-

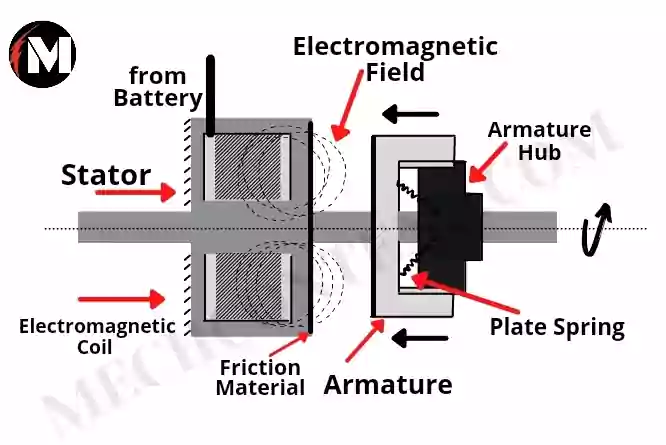

The below figure shows the basic diagram of this braking system.

The key components of the Electromagnetic Braking system are:-

1) Battery: The battery supplies the current to the electromagnetic coil whenever required to apply the brake.

2) Electromagnetic Coil:- It is a coil or spiral wire usually of copper that is located inside the stator. When the current flows from the battery to the coils, the electromagnetic field is produced around the coil.

3) Friction Material:- Friction material is attached to the stator to slow down or to stop armature rotation.

4) Armatur:- The Armature is made up of ferromagnetic material (Since the armature will get attracted towards the magnetic field) and it is mounted on the armature hub by means of splines.

Because of splines, the armature can easily slide on the armature hub. The armature is also connected to the armature hub by means of a plate spring. The Armature has a friction surface on one side.

5) Plate Spring:- Plate spring helps the armature to return to an initial position when the magnetic field is removed.

6) Armature Hub: The armature hub is used to mount the armature by means of splines. The armature hub is connected to the output shaft with the help of a key joint.

Working:-

Let’s see how brakes are applied and released:

Application of brake:

When the current supply from the battery starts to flow to the coil, the coil becomes an electromagnet and produces an electromagnetic field.

The electromagnetic field attracts the rotating armature towards the stator, Therefore friction occurs between the friction lining on the armature and the stator. Due to this friction, the armature stops and also stops the rotating shaft.

Hence in such a way brake is applied.

Releasing the brake:

When the supply of current to the coil stops, the coil stops creating an electromagnetic field.

Hence due to the removal of the electromagnetic field, the force of attraction on the armature gets removed and the stressed Spring pulls the armature towards the armature hub.

Hence in such a way brake is released and the armature and shaft can start rotating again.

Applications:-

This kind of braking system is used in the following applications:-

- Elevators & Escalators

- Medical Equipment

- Packaging & food processing machinery

- Servomotor & Robotics

Electromagnetic braking system advantages and disadvantages

The advantages of electromagnetic braking are:

- Less Maintenance

- Simple Construction

- Less Friction

- Less Noise

The disadvantages of electromagnetic braking are:

- Requirement of more electric power supply which discharges battery fast

- Chances of brake failure due to failure in electrical system.

Read also: