A Turbine, as we all know, is a device that transforms fluid energy into mechanical energy. In this article, we’ll study about a steam turbine, which uses steam to rotate the turbine.

A steam turbine is a rotating machine that converts the energy of the steam (by virtue of its pressure and temperature) into the mechanical energy of the rotor. For this purpose, the pressure energy of the steam is converted into kinetic energy and then it is utilized to move the moving blades that are mounted onto the rotor of the turbine.

Contents:

What is a steam turbine?

The steam turbine is one of the energy converters which converts the pressure energy of steam into mechanical energy in the form of the rotation of the shaft.

The modern steam turbine was developed in 1884 by Anglo-Irish engineer Charles Algernon Parsons.

In many industries and power plants, steam turbines are used for power generation or to drive different equipment like a pump, compressors, etc.

Principle:

In the steam turbine, the pressure of the steam is dropped partially or completely to increase the velocity (Kinetic energy) of the steam. This high kinetic energy steam is further passed over the ring of moving blades mounted on the rotor.

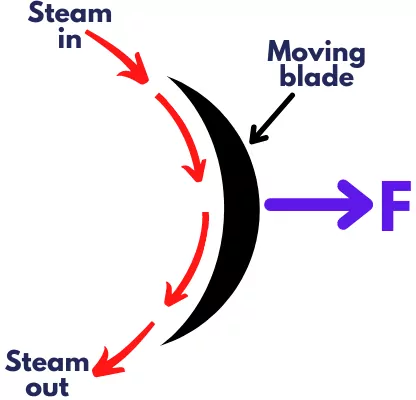

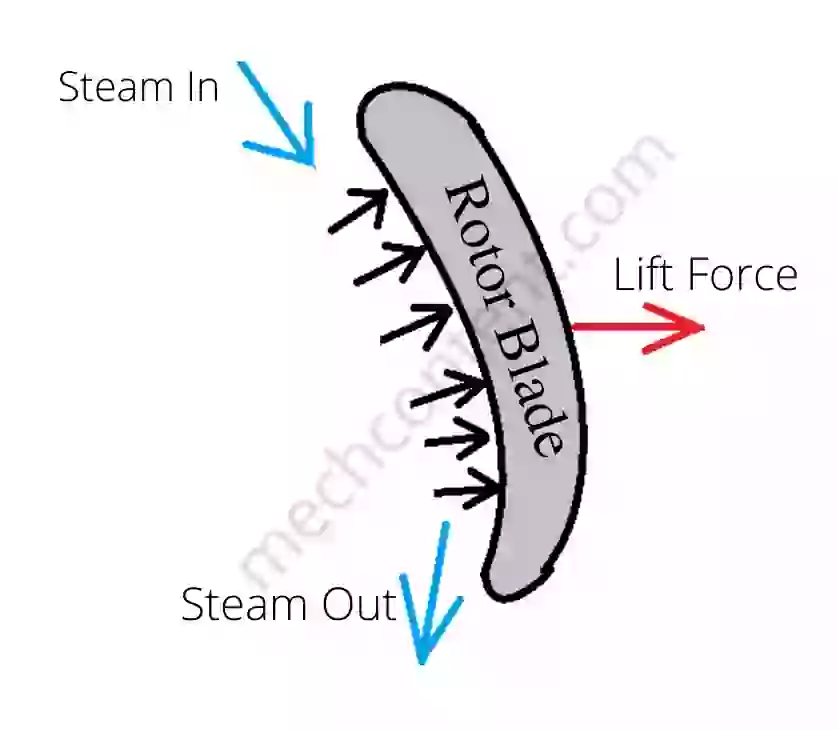

As shown in the above figure, after passing the steam onto the moving blades, the steam changes its direction and undergoes a change in momentum (As steam velocity gets decreased).

This results in creating an impulsive force (F) onto the moving blade. As the moving blade is mounted on the rotor, this force helps to rotate the turbine rotor.

Thus, in the steam turbine, the pressurized steam is expanded in multiple stages which causes the rotation of the turbine output shaft.

Types of steam turbine:

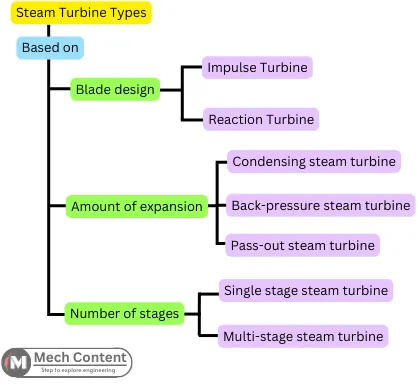

Steam turbines can be classified on the basis of different criteria that are discussed below.

Based on blade design:

Based on the blade design and the method of creating an impact on the blades, the turbines are classified as follows:

1] Impulse turbine:

In an impulse turbine, the blades are moved by the impulsive force developed by the high-velocity steam.

In an impulse turbine, the ring of fixed nozzles is used to convert the pressure energy of the steam into kinetic energy. Thus, the nozzles drop the pressure and increase the velocity of the steam as well as also help to provide direction to the steam.

After getting desired velocity and direction, the steam is passed over moving blades. Here the steam loses its velocity to rotate the moving blades of the turbine.

2] Reaction turbine:

While passing through the moving blades, the high-pressure steam undergoes expansion and gets accelerated. This acceleration of the steam develops the reaction force onto the moving blades. These types of turbines are known as Reaction turbines.

A reaction turbine consists of a number of sets of fixed blades and moving blades of aerofoil shape.

It doesn’t use the nozzles for the expansion as due to the aerofoil shape the moving blade and fixed blades act as a nozzle for the expansion of steam.

After passing the steam from the moving blade, the steam is passed over the set of stationary blades which gives direction and velocity to the steam, and then it further passed on the next set of moving blades.

Based on amount of expansion:

Depending on the exhaust of the steam from the turbine, the steam turbines are classified as follows:

1] Condensing steam turbine:

In the condensing steam turbine, the high-pressure steam is completely expanded up to the condenser pressure. This type of turbine is used in power plants that reuse the exhaust steam by condensing it into the condenser.

2] Back-pressure steam turbine:

In this type of steam turbine, the steam is expanded only up to certain intermediate pressure as this steam is further used as process steam for the different plant operations.

Example: If the steam generator produces steam at a pressure of 40 bar and for the heating, the chemical plant requires steam at a pressure of 8 bar. Thus, in this case, the back pressure turbine will expand the steam from a pressure of 40 bar to 8 bar.

The exhaust steam from with the remaining pressure from the turbine is used as a process steam in a chemical plant.

3] Pass-out steam turbine:

In this type of steam turbine, after the early phases of expansion, some steam is withdrawn at the intermediate stage, and the remaining steam is allowed to expand entirely up to the condenser pressure.

Based on number of stages:

Based on the number of stages, the steam turbine can be classified as follows:

1] single stage steam turbine:

In this type of turbine, the steam is expanded into the single stage of the turbine that includes a single ring of moving blades and a single nozzle ring.

2] multi-stage steam turbine:

This type of turbine consists of a number of stages, each stage consists of a ring of moving blades, ring of nozzles/fixed blades. It helps to extract the maximum energy of steam.

Steam turbine parts:

The steam turbine consists of the following components:

1) Nozzle:

The nozzle is used to convert high-pressure and low-velocity steam into low-pressure and high-velocity steam. It means that the pressure energy is converted into kinetic energy.

2) Rotor:

The rotor is the shaft of the turbine on which the moving blades are mounted. The output end of the rotor is coupled with the shaft of another device that needs power.

3) Moving blades:

The moving blades are mounted on the rotor. These blades are also known as rotor blades.

When the jet of high-velocity steam glides over the surface of the moving blade, the blade starts to move due to the resultant force created by steam.

In an impulse turbine, the passage between the moving blades has a constant cross-sectional area while in a reaction turbine, the passage between the moving blades has a variable cross-sectional area.

4) Fixed blades:

The fixed blades are mounted on the casing of turbine. These blades are also known as stator blades.

In an impulse turbine, the fixed blades are used to provide the direction to the steam while in the case of the reaction turbine, the fixed blades are used to expand the steam as well as to provide the direction to the steam.

5) Casing:

The casing creates an enclosure for the complete structure of nozzles and blades. The aim of the casing is to maintain the pressure inside the turbine and to avoid leakages from the turbine.

Working of steam turbine:

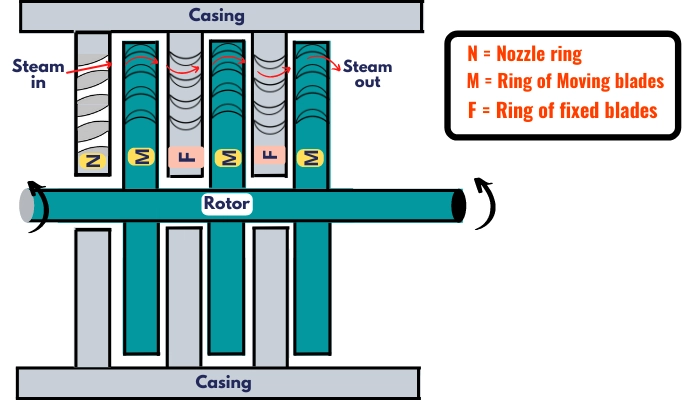

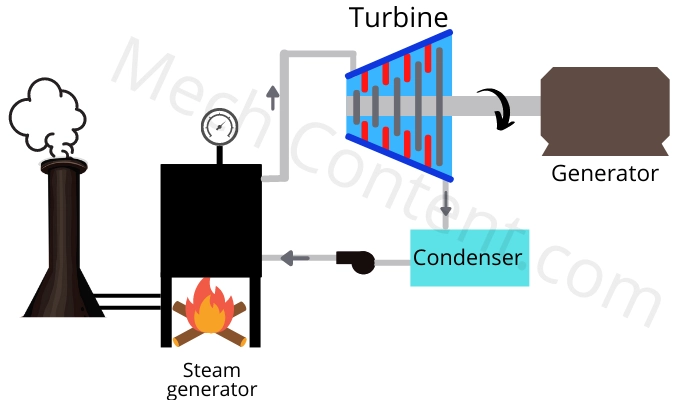

Let’s see how does a steam turbine works in a step-by-step manner with the help of the below figure.

The below figure shows the arrangement of moving blades, nozzles ring, and fixed blades inside the turbine casing.

In this arrangement, a set of moving blades and stationary blades (or set of nozzles) is known as a stage. Hence the number of stages varies as per application.

Step 1: Converting high pressure steam to high velocity steam:

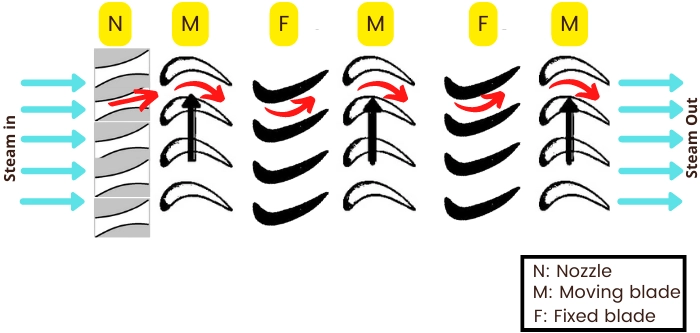

The high-pressure and superheated steam is first passed through the ring of nozzles where high-pressure steam is converted into higher velocity steam and it also gives direction to the flow of steam.

Step 2: Passing high velocity steam over rotary blades:

Now the high-velocity steam is passed over the moving blades of the turbine (As shown in the below figure).

When high-velocity steam passes through moving blades, it causes lift force on blades. Due to the lifting force, the moving blades start rotating along with the turbine rotor.

Step 3: Increasing velocity of steam and directing to next set of rotor blades:

After passing steam over the moving blades, the steam loses its velocity. Hence this low-velocity steam is not sufficient to produce lift force on the next set of moving blades.

Hence to increase the velocity of the steam, fixed blades are used after moving blades. These fixed blades are fixed to the turbine casing and are helpful in increasing the velocity of steam.

Step 4: Passing high velocity steam over next set of rotary blades:

After getting a sufficient amount of velocity and direction, the steam is passed over the second set of moving blades.

Therefore, steam is alternately passed through a set of moving blades and fixed blades. And the turbine shaft continuously rotates till steam flows inside the turbine.

Steam turbine efficiency:

The efficiency of the steam turbine can be given by the ratio of output work of the turbine to the energy supplied by the steam.

Mathematically, it can be stated as,

`\eta_{\text{turbine}}=\frac{\text{Work output}}{\text{Energy supplied}}`

The efficiency of the steam turbine can be stated by the use of below terms,

- Blade efficiency

- Stage efficiency

What is the back pressure in steam turbine?

The back pressure is the rise in the pressure at the turbine exit due to the lowering of the vacuum into the condenser.

Due to the presence of the non-condensing vapors or due to the failure of the vacuum pump, the vacuum inside the turbine gets lowered. Thus, it affects the rate of steam extraction from the exit of the turbine. This causes an increase in pressure at the turbine exit.

Thus because of the building of back pressure, the steam inside the turbine does not get expanded completely and a lot of energy gets wasted at the condenser. Thus, it lowers the power output and the turbine efficiency.

Applications:

Now we have understood the steam turbine but do you know where it is needed?

1] To rotate generator: The steam turbine is used for power generation in steam power plants. The turbine extracts the energy from the high-pressure steam to rotate the rotor. The output of the turbine is coupled with the shaft of the generator to produce electrical power.

2] To rotate pump or compressor: The steam turbine is also used as an alternative to electricity to rotate the different equipment like compressors, pumps, chillers, etc.

3] The steam turbine is also used for the combined purpose of power generation and heating. After the expansion of the steam into the turbine, the exhaust steam is used for heating in a chemical plant.

It was also used in old cargo ships to rotate the propeller of the ship.

FAQs:

-

What does a steam turbine do?

The steam turbine converts the pressure energy of steam into the mechanical energy of the shaft. This mechanical energy is further converted into electrical energy by generators at power stations.

-

Where is steam turbines used?

The steam turbine is generally used in power plants and industries to generate electricity with the help of a generator.

-

How many types of steam turbines are there?

The main two types of steam turbines are

1] Impulse turbine

2] Reaction turbine -

What is the working cycle of steam turbine?

The steam turbine is used in the Rankine cycle.

Thank you for reading. We have covered all of the information on the steam turbine, hope you enjoy it. If there any queries, leave them in the comments section below and we will gladly answer them.

Read also: