What is Hydraulic Braking System?

A hydraulic braking system in automobiles is a brake operating system that uses hydraulic fluid for its operation. Using this system, the driver can generate great braking force by applying less effort on the brake pedal.

This system is more efficient than the mechanical braking system.

It is a self-lubrication system hence no external lubrication is required. In this system, With less effort, we can achieve high braking force to stop the vehicle.

Continue reading to know more about its working principle, construction, working, advantages, applications, etc.

Contents:

Hydraulic Braking system working principle:

The hydraulic braking system works on the principle of Pascal’s Law.

PASCAL’S LAW:- The Pascal law states that “Pressure at any point in a static fluid is equal in all directions”.

Hence such pascal’s law is used in the hydraulic braking system to apply the brake.

Hydraulic Braking system construction:

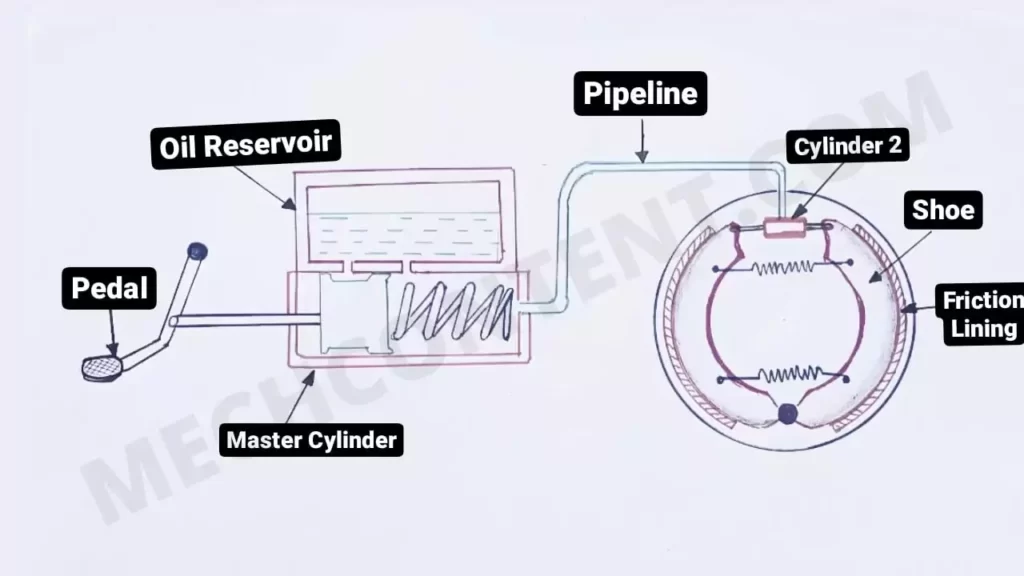

The below figure indicates, the structure of the hydraulic braking system:

A hydraulic braking system in Automobile consists of the following components:-

1) PEDAL: The brake pedal is pivoted and connected from the middle to the piston rod. When the brake pedal is pressed, the piston pushes the hydraulic oil inside the master cylinder.

2) MASTER CYLINDER:- It consists of piston, oil & return spring.

Return spring is used to maintain pressure on the piston therefore when the driver releases the brake pedal, the piston comes to its original position.

3) OIL RESERVOIR:- The oil reservoir is connected to the master cylinder which maintains the oil quantity inside the system.

4) CYLINDER 2:- It is located inside the wheel drum. It consists of two two-piston and the piston rods are connected to the shoes. When oil comes from the master cylinder, oil enters cylinder 2 and both pistons move out.

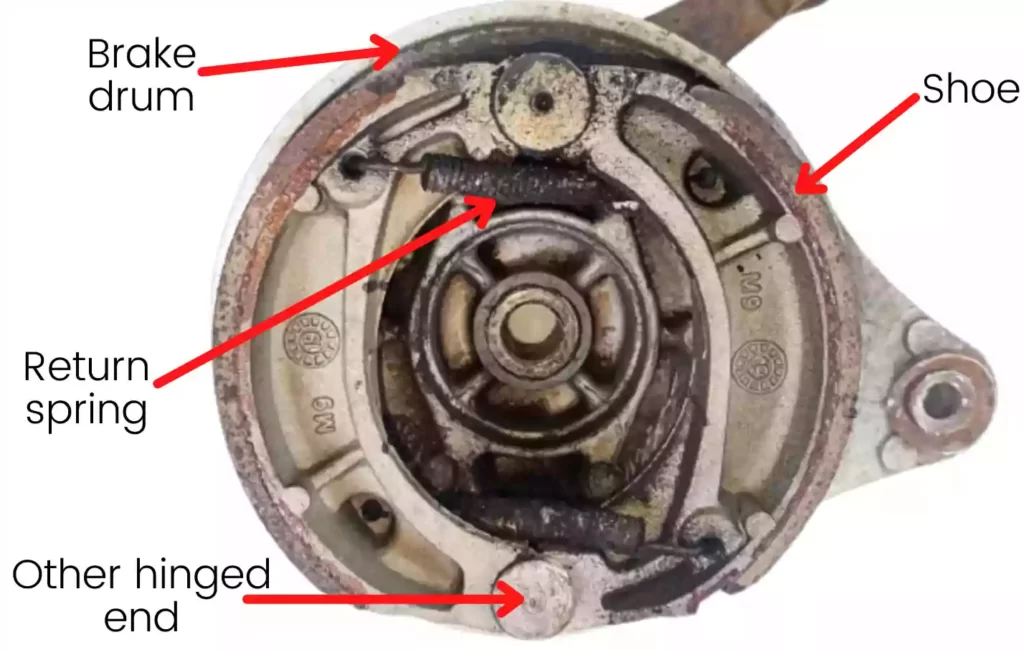

5) BRAKE SHOES:- There are 2 brake shoes used in the brake drum. Both piston rods are connected to one end of the shoes. Other ends of the shoes are hinged Brake shoes have friction lining on the outer surface.

Hence when the driver presses the pedal, the piston rods of cylinder 2 expand resulting in brake shoe expansion. Therefore due to friction between the shoes & brake drum, the wheel stops.

The shoes are connected with the return spring. Therefore When the driver releases the clutch pedal, pressure on the oil releases. Hence shoes come to their original position due to spring force.

6) PIPELINE:- It is used to flow oil from master cylinder to cylinder 2.

Hydraulic Braking system working:

Let’s see how the Hydraulic Braking system works to stop the wheel:-

When the driver presses the brake pedal, the piston pushes the oil inside the master cylinder.

Oil from the master cylinder moves to cylinder 2 through a pipeline/hose. As oil enters inside cylinder 2, both piston expands due to oil pressure.

Due to piston movement, brake shoes expand inside the brake drum. Therefore due to friction between shoes & brake drum, the wheel stops.

The cylinder bore of the master cylinder is smaller, thus the driver has to put less force over the pedal to build pressure on the oil.

While the bore of cylinder 2 is larger in comparison with the master cylinder. Therefore the brake force generated at cylinder 2 is higher.

Hydraulic Braking system advantages:

Hydraulic Braking System has the following advantages:-

- Fewer efforts are required to press the brake pedal

- It is a self-lubrication system hence no external lubrication is required.

- Simple Construction

- Smooth Operation

- Losses due to friction are much less.

Applications:

The hydraulic braking system is very popular in different applications like:-

- Buses

- Truck

- Car

Difference between hydraulic and mechanical brakes:

| Sr. No. | MECHANICAL BRAKES | HYDRAULIC BRAKES |

|---|---|---|

| 1 | Brakes are Less Powerful. | Brakes are more Powerful. |

| 2 | External Lubrication Required | No External Lubrication is required as it is a self-lubrication system. |

| 3 | Less effort is required for an operator to apply a Brake. | Less effort is required for an operator to apply Brake. |

| 4 | Less costly | It is costlier. |

| 5 | Friction Losses are more. | More efforts are required for an operator to apply Brake |

Read also about the other brakes: